Starting device of brushless doubly-fed machine

A technology for starting devices and electric motors, applied in starting devices, electronically reversing motor control, electrical components, etc., can solve the problems of excessive starting current, increase of motor supporting equipment and production and operation costs, and achieve cost saving and quantity reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with the following examples.

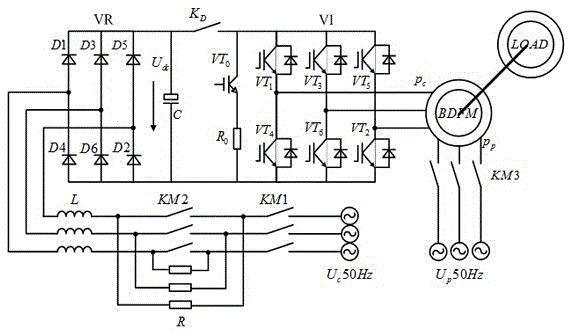

[0024] The starting method of the brushless doubly-fed motor of the present embodiment, such as figure 1 As shown, the motor has been connected with power winding P p , control winding P C And the frequency converter, the DC output side of the frequency converter is connected in parallel with the braking resistor and the three-phase full-bridge inverter circuit VI, and the output terminal of the three-phase full-bridge inverter circuit VI is connected through the control winding P C Connected to the motor, the method comprises the steps of:

[0025] Step A: In the inverter bus capacitor C and braking resistor R 0 The busbars between are connected in series with a busbar switch K D , and then disconnect the bus switch K D to disconnect the DC output of the inverter;

[0026] Step B: braking resistor R 0 A brake switch VT is connected in series 0 , turn on the brake unit switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com