Component pick-up heads for surface mount machines

A technology for placement machines and components, applied in electrical components, electrical components, etc., can solve problems such as sufficient detection accuracy, and achieve the effects of improving detection accuracy, controlling descending stroke, and smooth lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the present invention according to preferred embodiments will be described in detail with reference to the accompanying drawings. In addition, in this specification and drawings, the same code|symbol is used for the component which has substantially the same structure, and overlapping description is abbreviate|omitted.

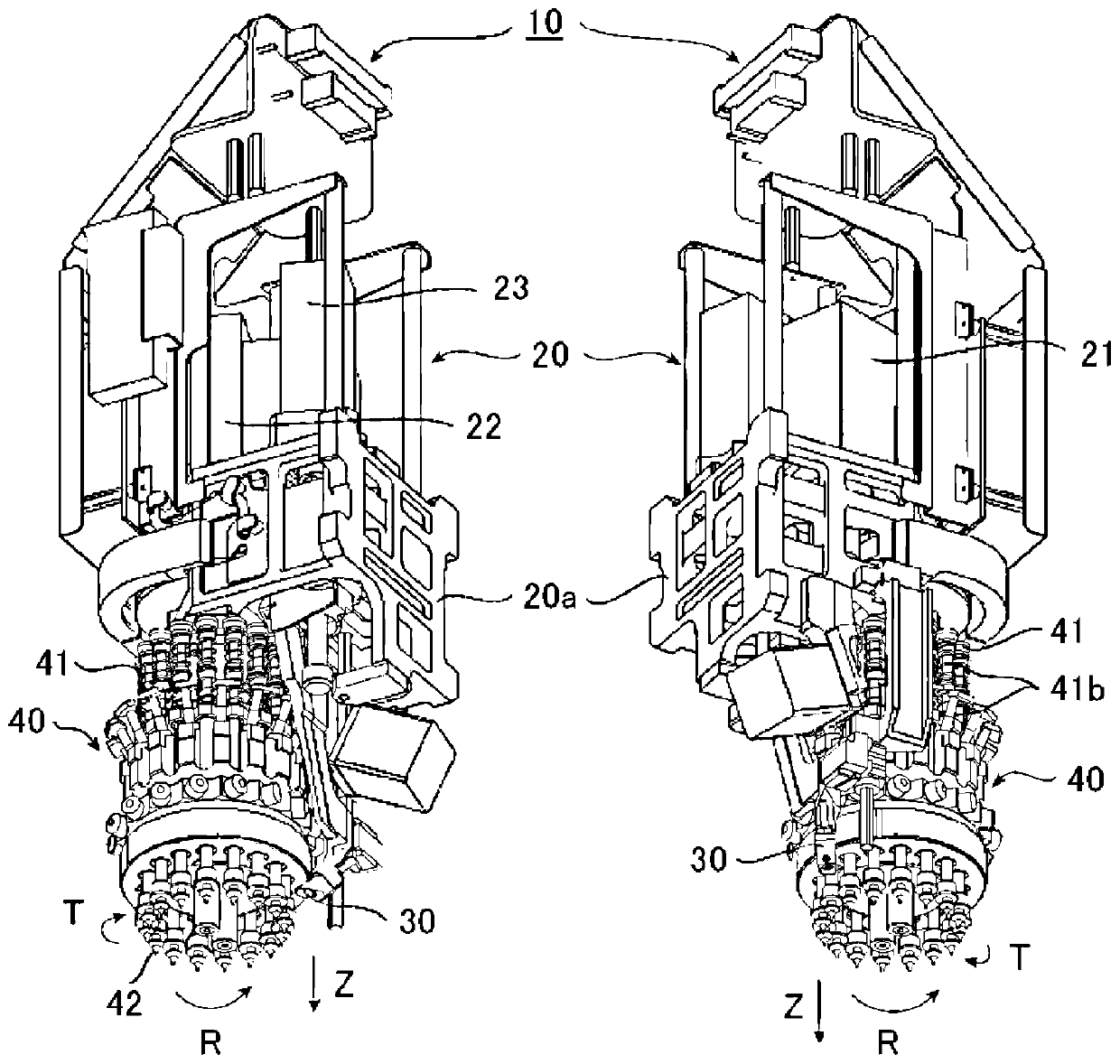

[0045] figure 1 It is a perspective view showing the overall configuration of a component suction head according to an embodiment of the present invention.

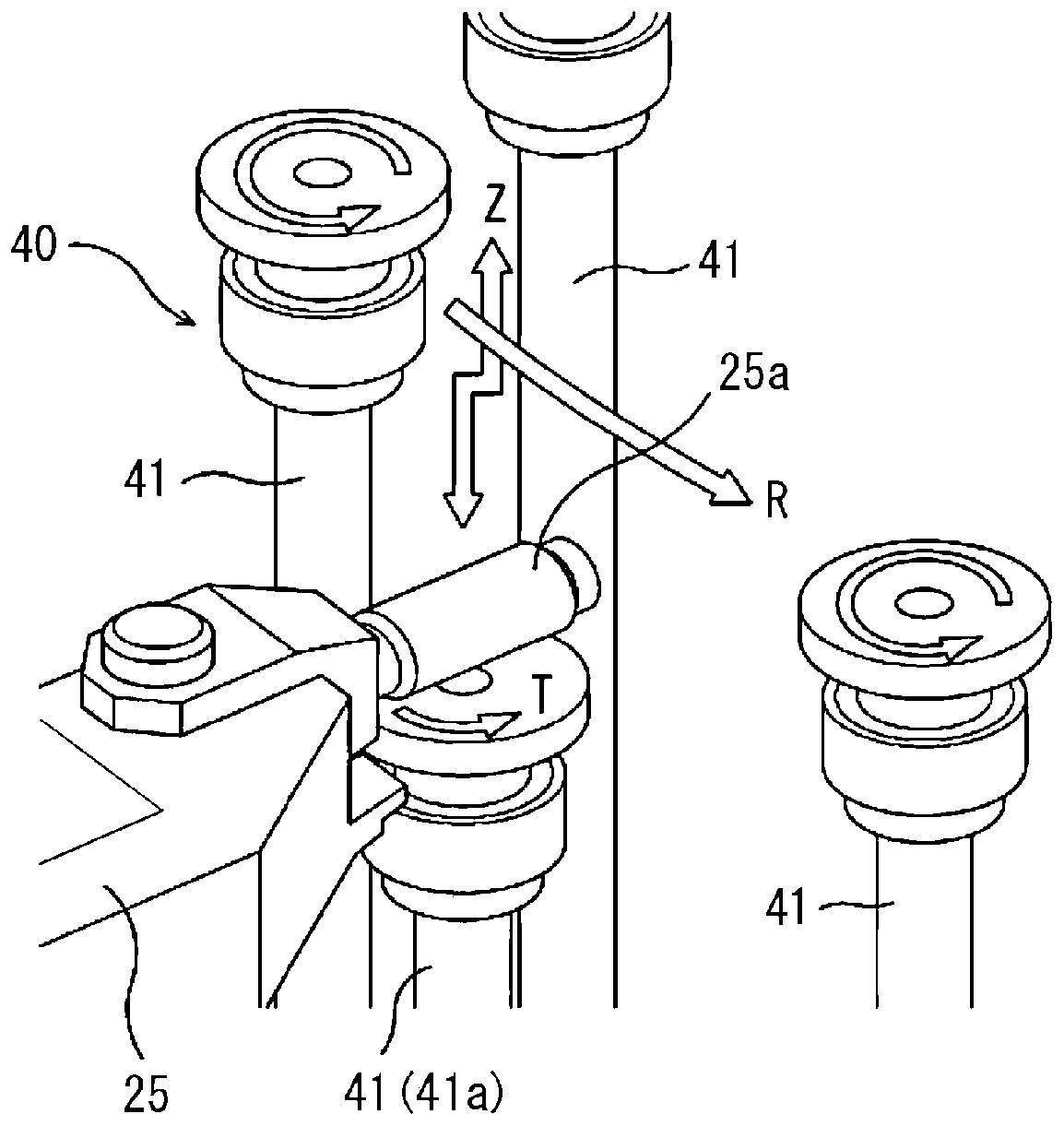

[0046] Such as figure 1 As shown, the component holding head 10 is a rotary head type component holding head, and the rotary head 40 is mounted on the head main body (main frame) 20 so as to be rotatable in the R direction around the vertical axis. In the spin head 40, a plurality of main shafts 41 are arranged at equal intervals along the circumferential direction, and a suction nozzle 42 is attached to the lower end of each main shaft 41 as a component holding mechanism for sucking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com