Remote bone cement filling device

A filling device and bone cement technology, applied in the direction of the fixer, can solve the problems of single propulsion mode and short length, and achieve the effects of good control, kink prevention, and large selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

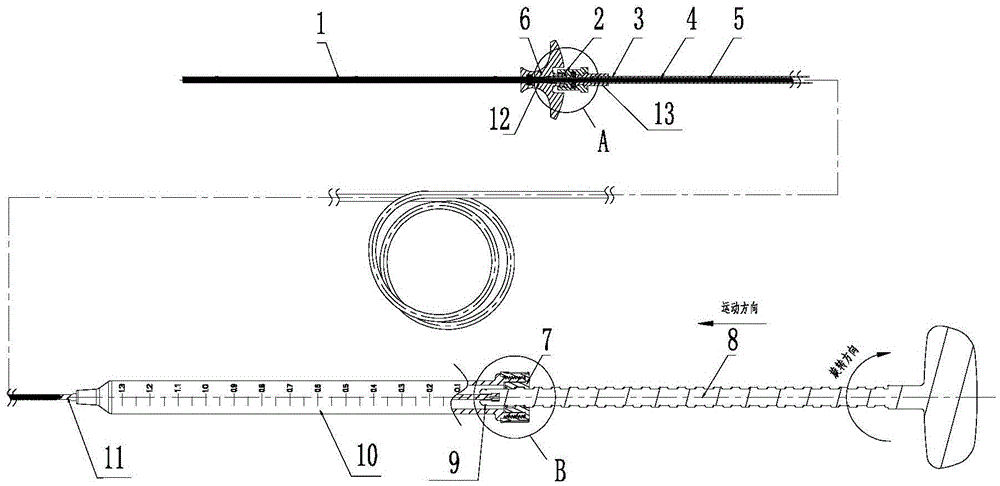

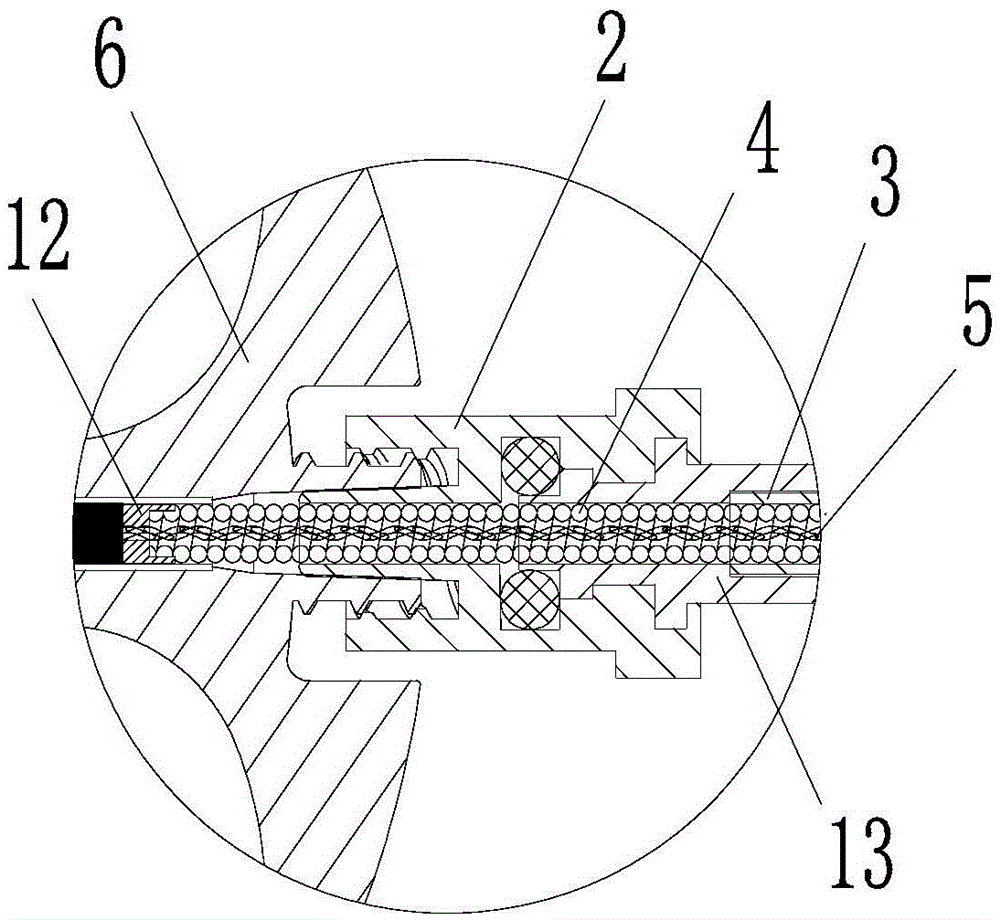

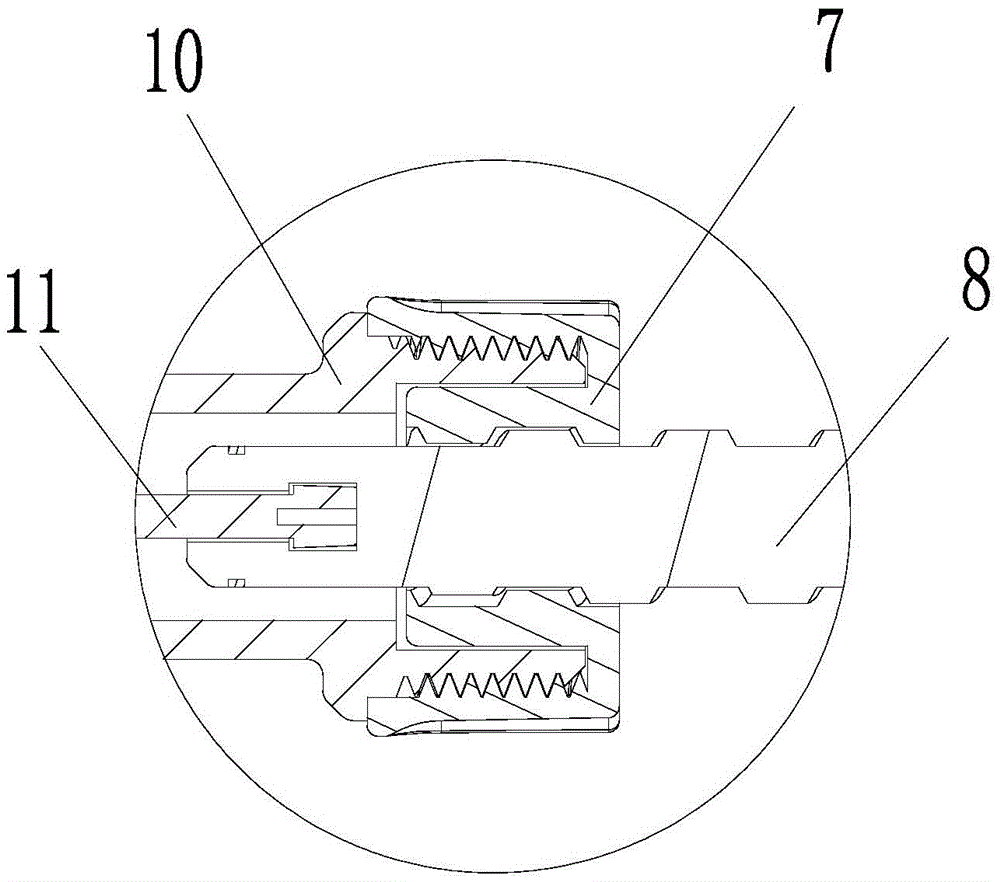

[0034] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0035] Such as Figure 1 to Figure 3 As shown, a remote bone cement filling device includes a sleeve 1, an outer tube 3 and a threaded outer tube 10, the front end of the outer tube 3 is connected to the rear end of the sleeve 1, and the rear end of the outer tube 3 is connected to the front end of the threaded outer tube 10. connection, the casing 1 is provided with a movable plug 12, the outer tube 3 is provided with a spring tube 4, the threaded outer tube 10 is provided with a push rod 8, and the push rod 8 passes through the rear end wall of the threaded outer tube 10 and is connected with the The rear end wall of the threaded outer tube 10 forms a sliding fit, or the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com