Coal picker

A coal preparation machine and clean coal technology, applied in solid separation, chemical instruments and methods, grids, etc., can solve the problems of increased labor burden on workers, high cost of coal preparation process, short residence time, etc., to reduce labor burden, Good coal preparation effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

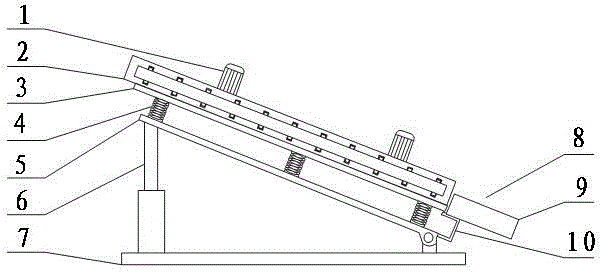

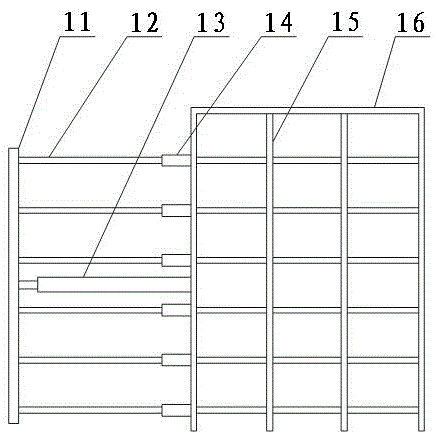

[0026] As shown in the figure, a coal separator of this patent is used to screen clean coal from raw coal, and its features include: a base 7, fastening bolts, a height adjustment device 6, a clean coal slideway 5, a vibrating screen 3, Vibration motor 1, mounting frame, retention device 2 and coal discharge device 8.

[0027] The base 7 is provided with a bolt through hole, and the fastening bolt passes through the bolt through hole to fasten the base 7 on the ground; the height adjustment device 6 is two hydraulic cylinders, and the two hydraulic cylinders are vertically arranged at one end of the base 7; One end of the slideway 5 is connected to the piston rods of two hydraulic cylinders, and the other end is hinged with the base 7. The hydraulic cylinder can adjust the slope of the clean coal slideway 5 through the expansion and contraction of the piston rods; the vibrating screen 3 is arranged above the clean coal slideway 5, and It is connected with the clean coal slidew...

Embodiment 2

[0032] Same as Embodiment 1, wherein the electric push rod 13 in the retention device 2 is replaced by a hydraulic cylinder or an air cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com