Control system and method for dry method sorting device

A sorting device and control system technology, which is applied to chemical instruments and methods, solid separation, and separation of solids from solids with airflow, can solve problems affecting coal preparation efficiency and low intelligence, and achieve improved coal separation. Coal quality, good effect, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

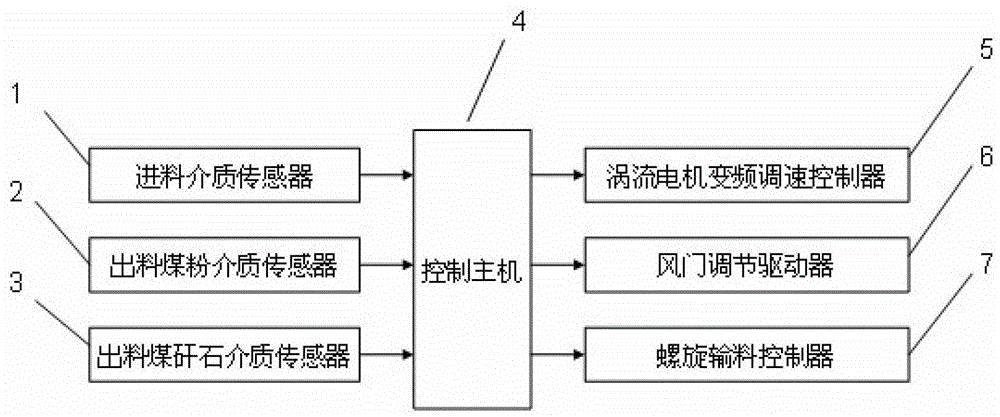

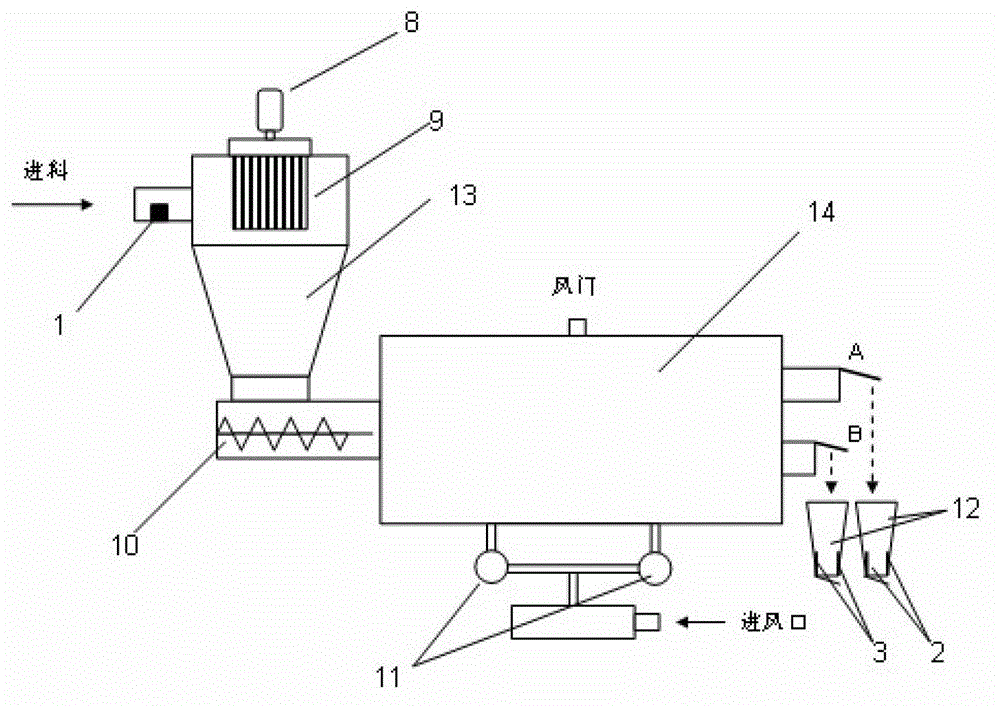

[0018] like figure 1 shown. The control system of the dry separation device of the present invention is mainly composed of a feed medium sensor 1, a discharge coal powder medium sensor 2, a discharge coal gangue medium sensor 3, a control host 4, a turbine motor frequency conversion speed regulation controller 5, and an air door adjustment driver 6 and screw feed controller 7 constitute.

[0019] The input end of the control host 4 is respectively provided with a feed medium sensor 1 located at the feed inlet of the turbine sorting device 13 and a discharge coal powder medium sensor located at the pulverized coal outlet A of the winnowing device 14 2 and the discharge coal gangue medium sensor 3 at the coal gangue discharge port B, the output end of the control host 4 is respectively provided with an eddy current motor frequency conversion speed controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com