Production die for opened profiles

One type, mold technology, applied in the production field of open-type profiles, can solve problems that affect the quality of profiles, mold life, mold cantilever deformation, unfavorable metal flow, etc., to achieve force relief, quality and mold life assurance, and simple processing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

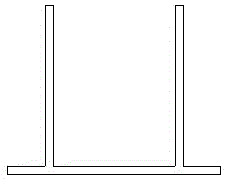

[0018] figure 1 A cross-sectional view of a typical open profile is shown.

[0019] below to produce figure 1 The profile shown is an example to design the mold.

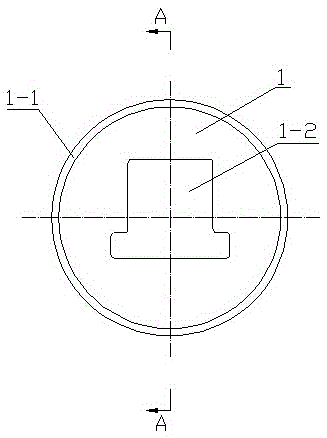

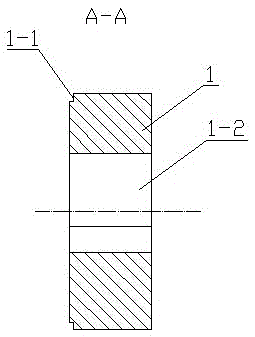

[0020] Such as Figures 2 to 8 Shown: the present invention mainly is made up of upper mold 1 and lower mold 2. Steps 1-1 and 2-1 that cooperate with each other are respectively arranged on the opposite surfaces of the upper mold 1 and the lower mold 2, and the upper mold 1 and the lower mold 2 are connected to each other through the steps 1-1 and 2-1.

[0021] A diversion hole 1-2 is provided at the center of the upper die 1, and an extrusion hole 2-2 consistent with the shape of the opening profile is provided on the lower die 2 below the diversion hole 1-2. The lower die 2 inlet end of the graphic center surrounded by the extrusion hole 2-2 is provided with a splitting table 2-3, and the splitting table 2-3 protrudes from the plane of the lower die 2 inlet end, and stretches into the guide of the upper die 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com