Cutting insert with asymmetric cutting edge

一种切削刀片、切削刃的技术,应用在双面正方形可转位的切削刀片领域,能够解决增加高度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

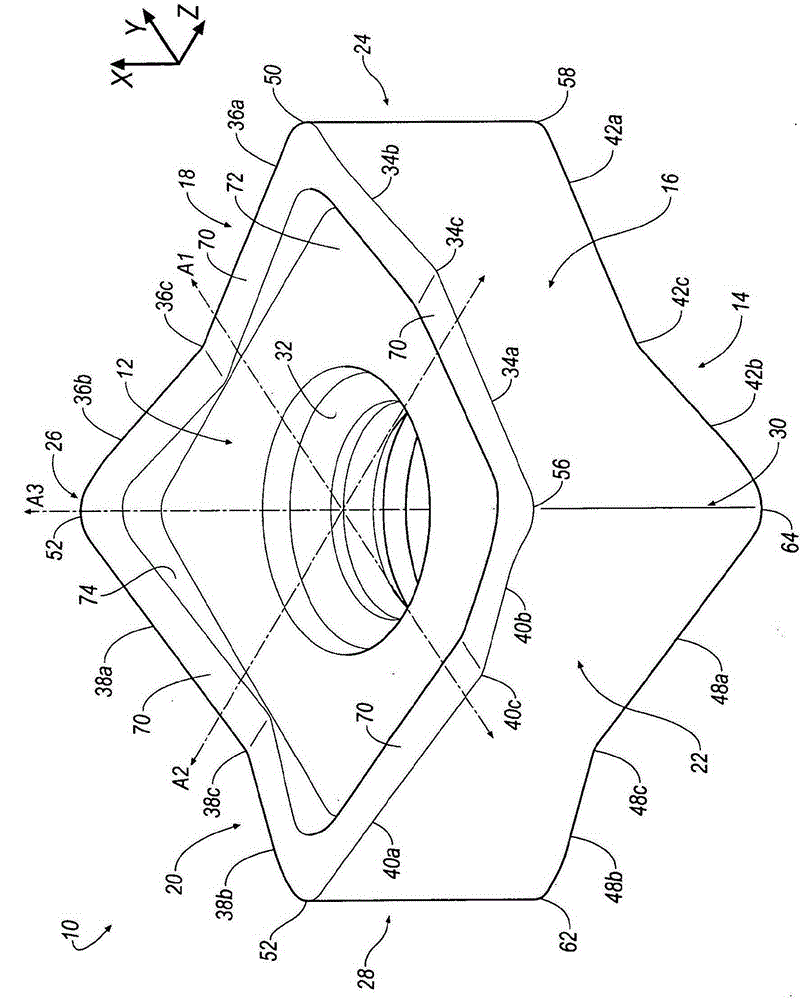

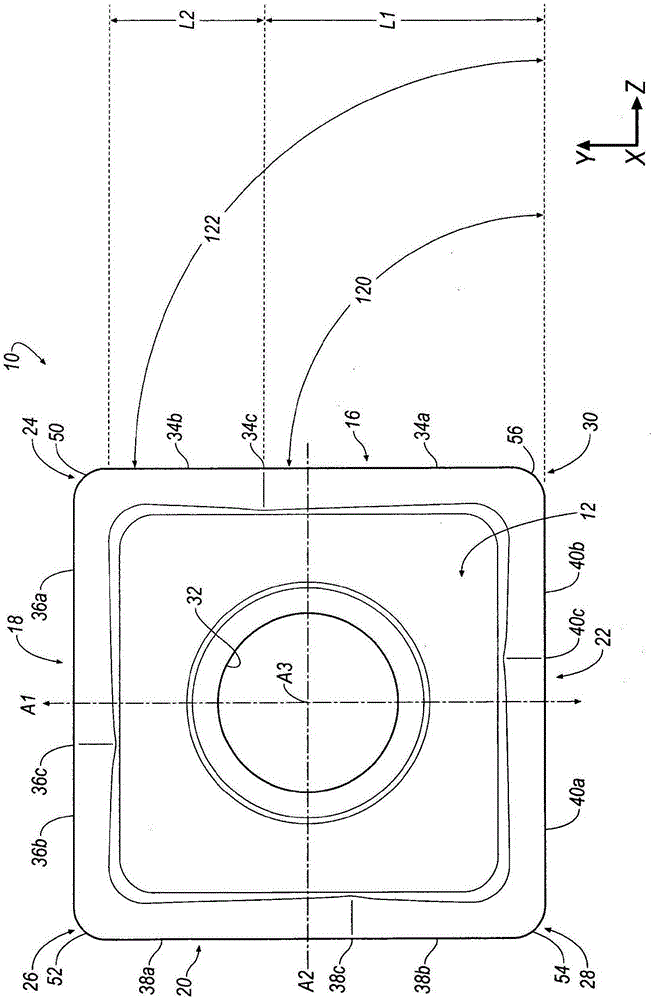

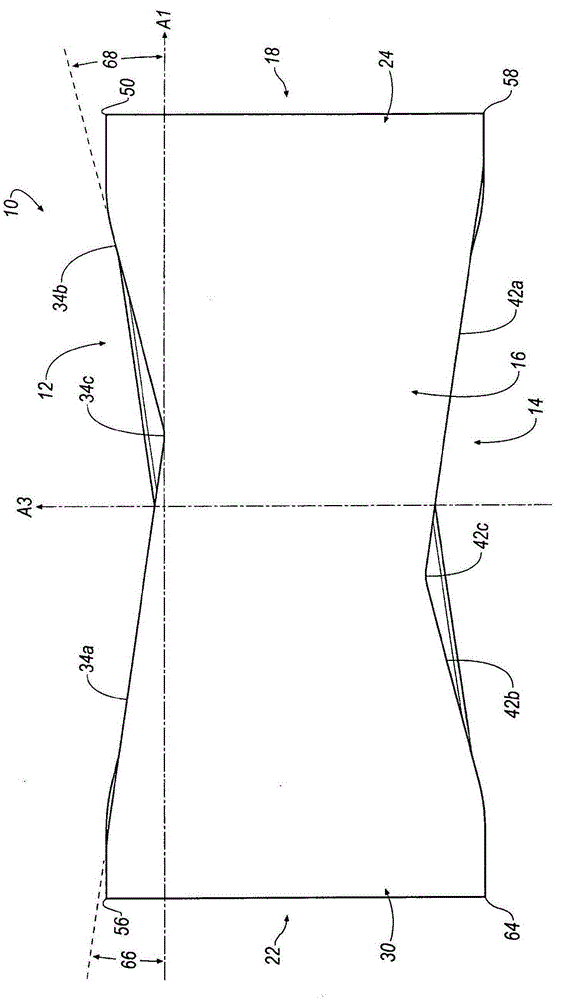

[0014] see now Figure 1-Figure 3 , shows a cutting insert 10 according to an embodiment of the invention. In general, the cutting insert 10 is double-sided, indexable and equidistant. The cutting insert 10 is typically manufactured by forming pressed and cemented carbide powder using methods known in the art. The cutting insert 10 is generally square in shape and has two identical opposing first and second surfaces 12, 14, and four circumferential side surfaces 16 extending entirely between the first and second surfaces 12, 14. , 18, 20, 22. The first surface 12 and the second surface 14 are substantially identical to each other, and the four circumferential side surfaces 16, 18, 20, 22 are substantially identical to each other. The cutting insert 10 also includes four curved corners 24 , 26 , 28 , 30 extending entirely between the first surface 12 and the second surface 14 and adjacent circumferential side surfaces 16 , 18 , 20 , 22 . The first surface 12 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com