Cutting mechanism with clamping device

A technology of cutting mechanism and clamping device, which is applied in the direction of shearing device, accessory device of shearing machine, metal processing equipment, etc., and can solve problems such as difficult cutting of cutting machine fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

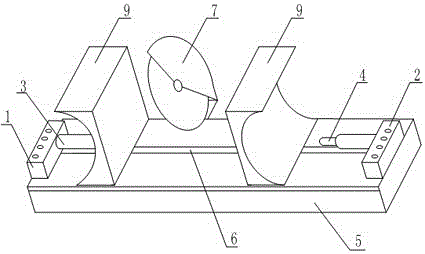

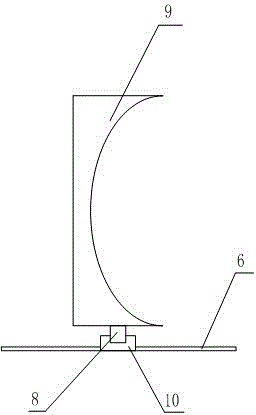

[0020] Such as figure 1 and figure 2 The shown cutting mechanism with its own clamping device includes a base 5 and a cutting mechanism 7, the cutting mechanism 7 is arranged on the rear side edge of the base 5, and the left and right ends of the upper surface of the base 5 are respectively provided with The first drive motor 1, the second drive motor 2, the output ends of the first drive motor 1 and the second drive motor 2 are respectively connected with the first electric push rod 3, the second electric push rod 4, on the base 5 The surface is also provided with a chute 6, and two sliders 10 are arranged in the chute 6, and each slider 10 is provided with a vertical rotating shaft 8, and each rotating shaft 8 is fixedly connected with a clamping Plate 9, each clamping plate 9 is that one side is a plane, and the other side is a curved surface; the cutting mechanism 7 is an electric cutter, and the cutting mechanism 7 also includes a motor and a propulsion device; the firs...

Embodiment 2

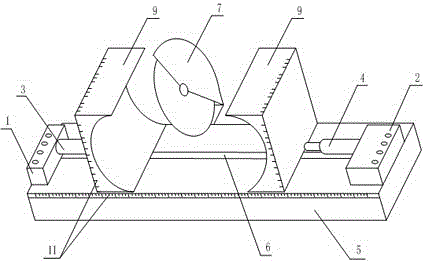

[0022] Such as image 3 In the shown cutting mechanism with its own clamping device, on the basis of Embodiment 1, the sides of the base 5 , the sides and the top surface of the clamping plate 9 are provided with scale bars 11 . The size scale bar 11 can be used to determine the specific position of the cutting place of the workpiece to be cut, so as to improve the processing accuracy.

Embodiment 3

[0024] Such as Figure 1 to Figure 3 In the shown cutting mechanism with a clamping device, on the basis of any of the above-mentioned embodiments, the chute 6 is arranged in the middle of the upper surface of the base 5, and the width of the clamping plate 9 is the same as that of the base 5 have the same width. If the chute 6 is arranged in the middle of the upper surface of the base 5, the slider 10 and the rotating shaft 8 will all be located in the middle of the entire device, ensuring symmetry and ease of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com