Transformer oil tank main body

A technology of transformer oil tank and main body, applied in the field of transformers, can solve the problems of easy damage, falling off, fixing, etc., and achieve the effects of increasing air flow speed, reducing workload, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

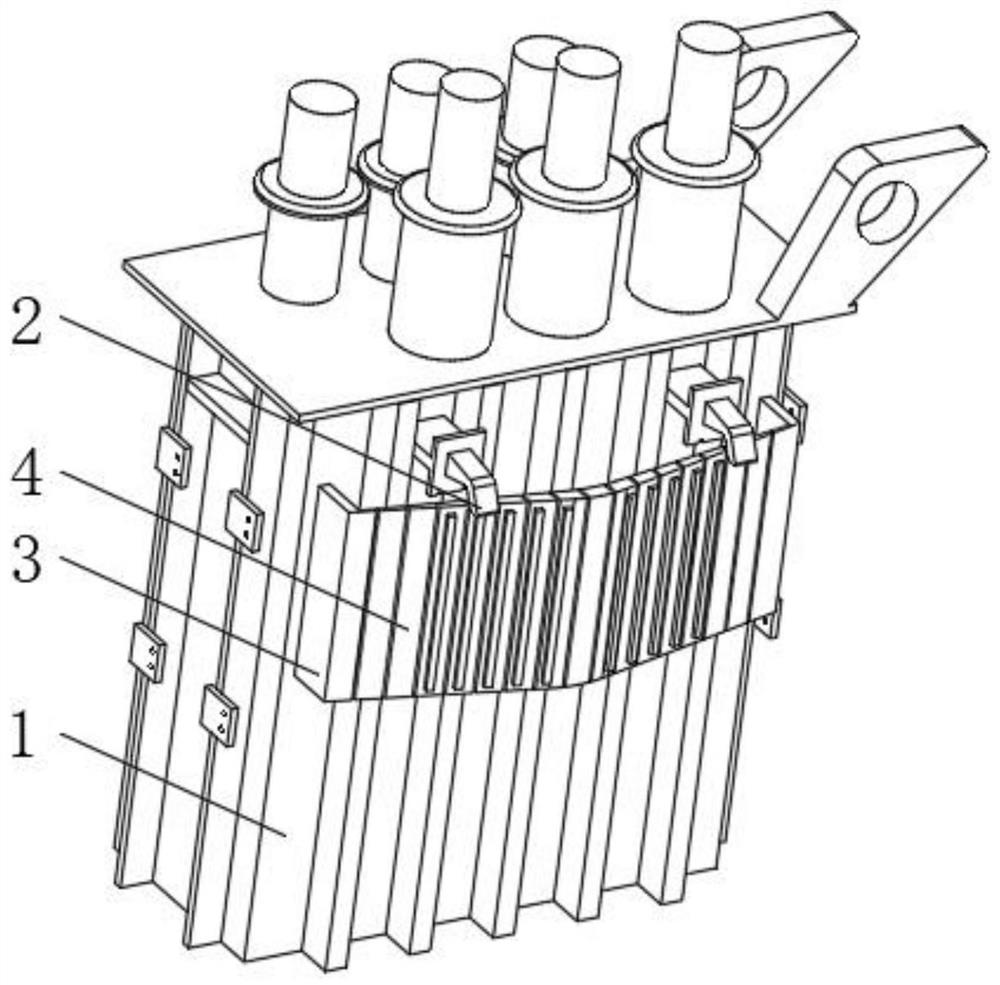

[0033] see Figure 1-3 , the present invention provides a technical solution: a main body of a transformer oil tank, including an oil tank 1, the outer side of the oil tank 1 is fixedly connected with a hook 2, both sides of the oil tank 1 are fixedly connected with an extension plate 3, and between the two sides of the extension plate 3 Settings are:

[0034] Guide device 4, the guide device 4 has a guide veneer 41, the surface of the guide veneer 41 is a magnetic metal material, one side of the guide veneer 41 is fixedly connected with an arc-shaped bump 42, and the guide veneer 41 is away from the arc-shaped bump One side of 42 is provided with an arc-shaped slot 43;

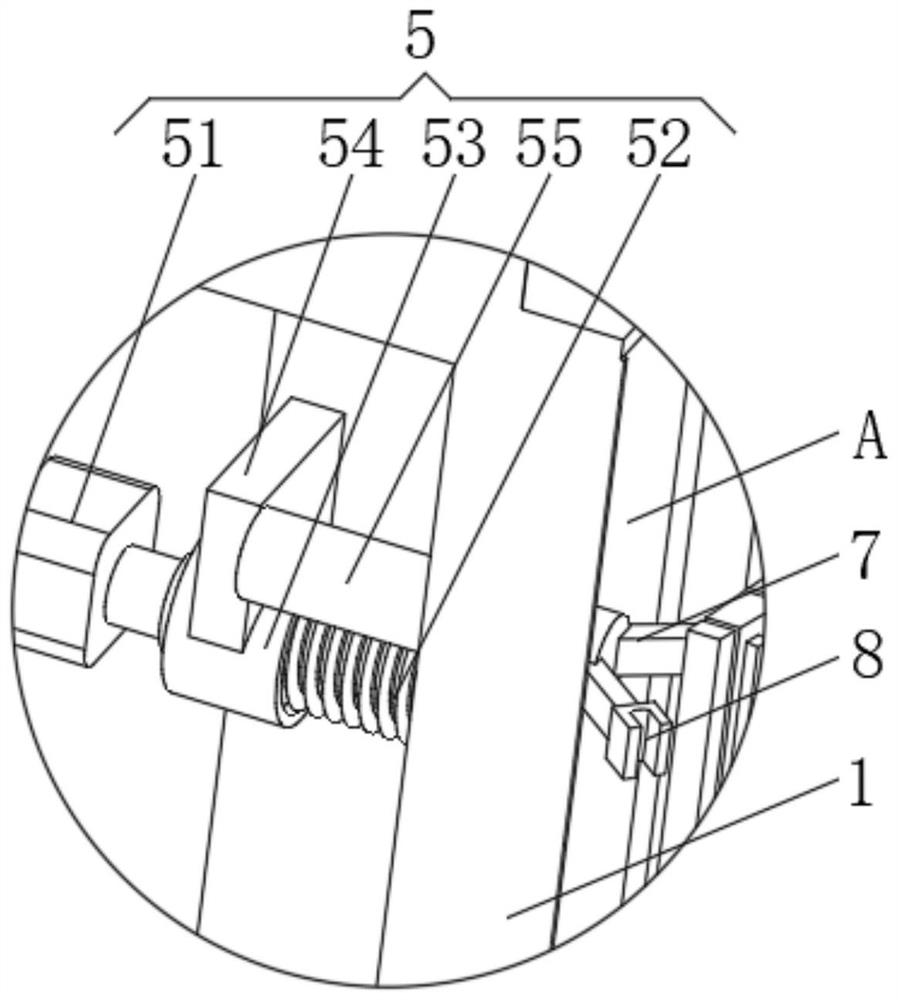

[0035]Pushing device 5, this pushing device 5 has driving motor 51, and the output end of driving motor 51 is fixedly connected with externally threaded rod 52, and the outside of externally threaded rod 52 is provided with threaded sleeve 53, and the top of threaded sleeve 53 is fixedly connected with A lo...

Embodiment 2

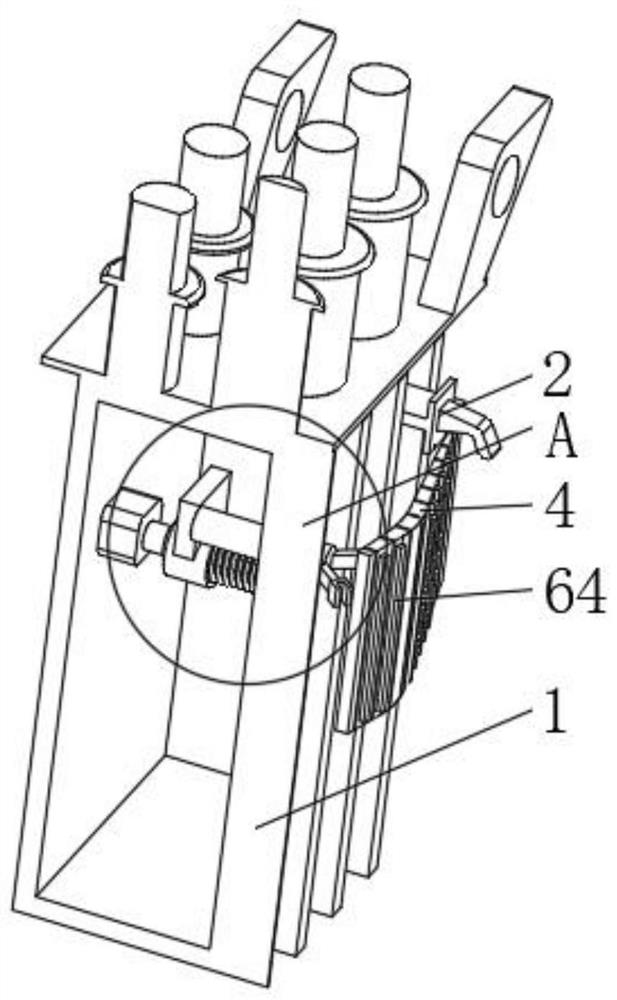

[0039] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, a separation device 6 is provided between the two sides of the epitaxial plate 3, the separation device 6 has a separation groove 61, and the separation groove 61 runs through the guide veneer 41 and the arc One side of the inner wall of the separation groove 61 is fixedly connected with a magnet block 62, and one side of the inner wall of the separation groove 61 is fixedly connected with a buffer spring 63 near the position of the magnet block 62, and one end of the buffer spring 63 is fixedly connected with a force-bearing block 64 , the force bearing block 64 penetrates the guiding veneer 41 and extends to the outside of the guiding veneer 41 .

[0040] One end of the push rod 55 extending to the outside of the fuel tank 1 is symmetrically equipped with a swing rod 7 , the swing rod 7 is rotationally connected with the push rod 55 , and the end of the swing rod 7 awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com