Claw-type manipulator with telescoping and rotating functions

A manipulator and claw-type technology, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve problems such as inaccurate grasping, damage to equipment, and falling, so as to ensure the reliability of grasping, diversification of actions, and grasping get precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

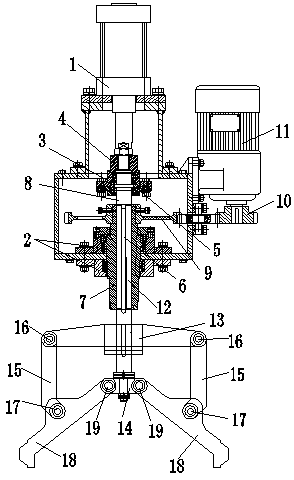

[0009] Combine below figure 1 Specific description embodiment:

[0010] A claw-type manipulator device with telescopic and rotating functions, including a cylinder 1 and a bearing seat 2, the output end of the cylinder 1 is connected with a connecting rotary joint 3, and the connecting rotary joint 3 includes a housing 4, inside the housing 4 A bearing 5 is provided, the housing 4 is fixedly connected with the output end of the cylinder 1, the bearing 5 is connected with the main shaft 6; the bearing housing 2 is provided with a rotating hollow shaft 7, and the rotating hollow shaft 7 is provided with There is a shaft key 8. The shaft key 8 passes through the rotating hollow shaft 7 and then enters the connecting rotating joint 3 to connect with the bearing 5. The outer wall of the rotating hollow shaft 7 is connected with a driving gear 10 through a driven gear 9. The driving gear 10 is connected with a motor 11; the hollow rotating shaft 7 is provided with a through hole 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com