Wood splitting locating and anti-vibration mechanism of combined wood splitting device

A combined and equipment technology, applied in the direction of wood splitting devices, wood processing appliances, manufacturing tools, etc., can solve the problems of poor wood splitting effect, unstable vibration, serious energy consumption, etc., to ensure the wood splitting effect, convenient operation, The effect of timely adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

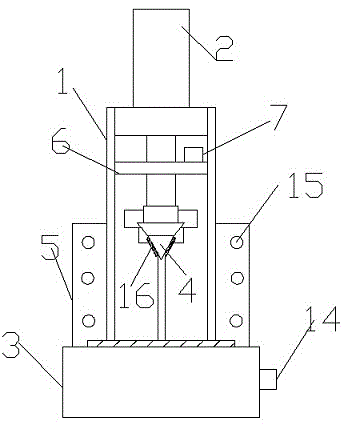

[0015] Such as figure 1 , 2 Shown: the wood splitting positioning anti-shock mechanism of a kind of combined wood splitting equipment of the present embodiment, includes supporting frame body 1, hydraulic cylinder 2, anti-vibration backing plate 3 and chopping knife 4; Both sides of described supporting frame body 1 are A baffle 5 is provided; wherein each surface of the baffle 5 is provided with several protrusions 15 .

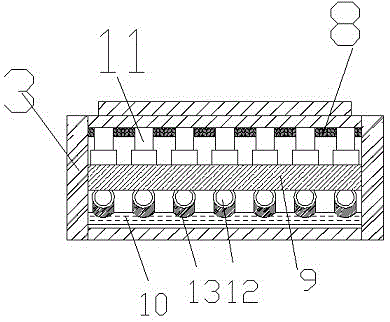

[0016] The hydraulic cylinder 2 is fixed on the top of the support frame 1 and the hydraulic shaft passes through the support plate 6 and is connected and fixed with the chopper 4. The support plate 6 is provided with a positioning sensor 7; 3 One side is connected to the weight sensor 14, and the inner cavity is provided with a rubber pad 8, a plywood 9 and a bottom plate 10 in sequence; the top of the inner cavity of the anti-vibration back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com