Suction cup glaze dipping machine

A glaze dipping machine and sucker technology, which is applied in the field of daily-use ceramics production equipment, can solve the problems of unable to meet daily production needs, complex structure of glazing device, high cost, etc., and achieve high-efficiency glazing, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

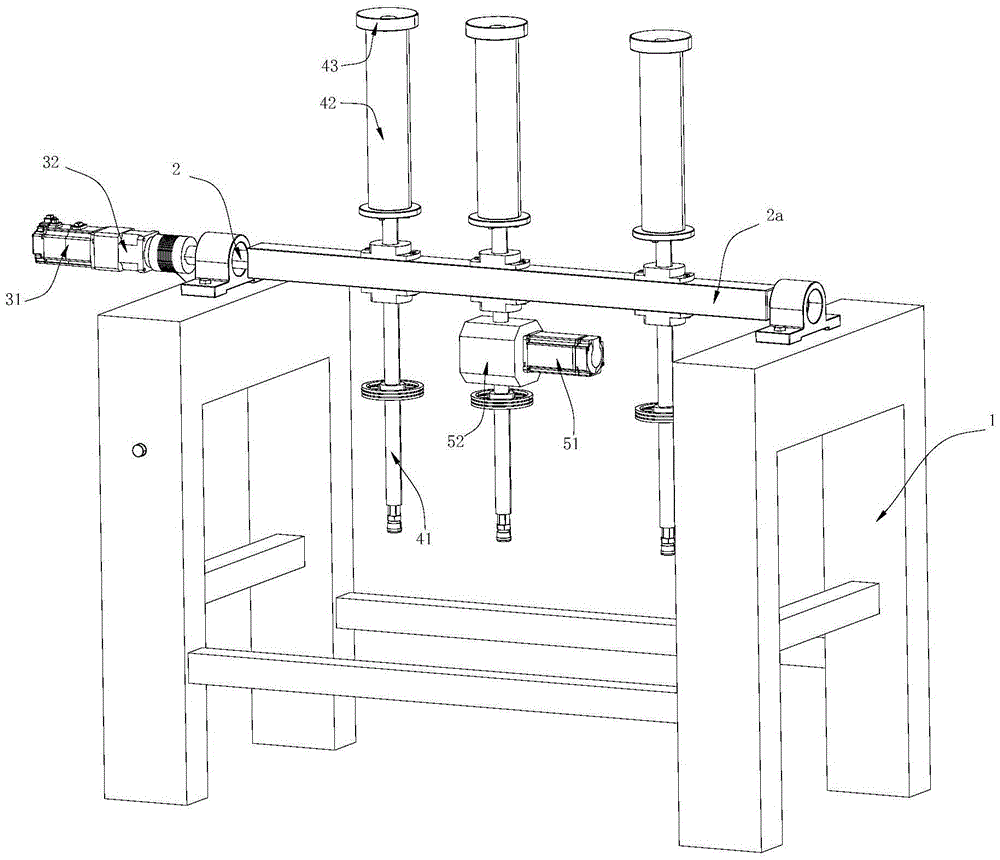

[0016] like figure 1 The suction cup dipping machine shown includes a base 1, a turning shaft 2 arranged on the base 1, a revolution drive mechanism for driving the turning shaft 2 to rotate, and three sets of glaze dipping assemblies arranged on the turning shaft 2 . The revolving drive mechanism includes a revolving motor 31 and a reduction box 32 connected to the output shaft of the revolving motor 31 ; Both ends of the overturning shaft 2 are positioned on the base 1 through bearings, the overturning shaft 2 between the bearings on both sides is a rectangular columnar body, and the three sets of dipping glazing assemblies are all positioned on the rectangular columnar part 2a of the overturning shaft 2 through the bearings.

[0017] The three sets of glaze dipping assemblies are arranged parallel to each other, and the dippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com