Device for controlling sinker to be opened and closed and full-automatic computerized flat knitting machine adopting device

A sinker and right-sliding technology, which is applied to flat knitting machines with individual moving needles, textiles, papermaking, knitting, etc., can solve the problems affecting the quality of knitting needle knitting and transfer, and the floating of old loops, so as to achieve knitting Sufficient, the quality of clothing pieces is improved, and the effect of ensuring the quality of transfer rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

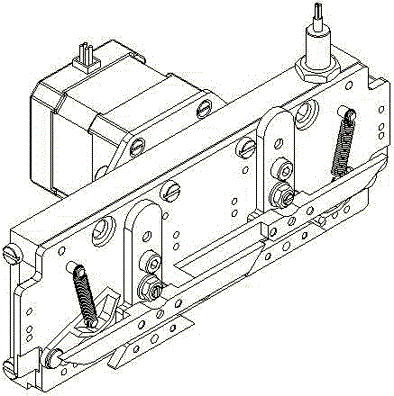

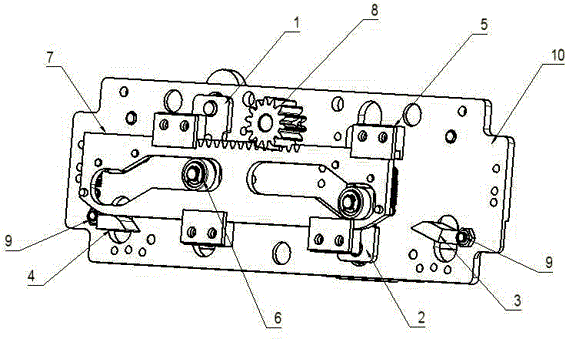

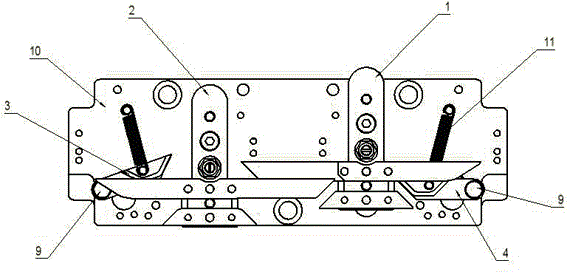

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

[0023] A device for controlling the opening and closing of the sinker of the present invention is an improvement to the existing sinker control device, aiming at solving the problem that the sinker in the existing control device cannot press down the old loops carried by the knitting needle when the yarn is bent. action, causing the old coil to float up.

[0024] Therefore, the present invention provides a device for controlling the opening and closing of the sinker to improve the quality of knitting and transfer by adding a push-down action to the old loops brought up by the knitting needle when the yarn is bent. The core technology of the control device of the present invention lies in the addition of a pressing action, that is, there are three processes in the opening and closing process of the sinker, closing-opening-closing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com