Laminboard socket rubber strip and application node structure thereof

A sandwich panel and plug-in joint technology, which is applied to building components, building structures, building insulation materials, etc., can solve the problems of rainwater penetration at the joints and cold bridges easily caused by the insulation layer, so as to increase the flatness and Aesthetics, guaranteed service life, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Example description

[0052] The sandwich panel plug-in joint rubber strip and its application node structure of the present invention are suitable for the transverse splicing of two curtain wall panels. The core boards are fixed on the wall purlins or columns by screws, and then the lower end of the upper sandwich board is plugged into the upper groove of the lower sandwich board, so that the sandwich board plug-in interface rubber strip fills the space between the upper and lower sandwich boards. Joints, so as to make the insulation layer of the upper and lower sandwich panels continuous and prevent rainwater from penetrating from the joints.

specific Embodiment

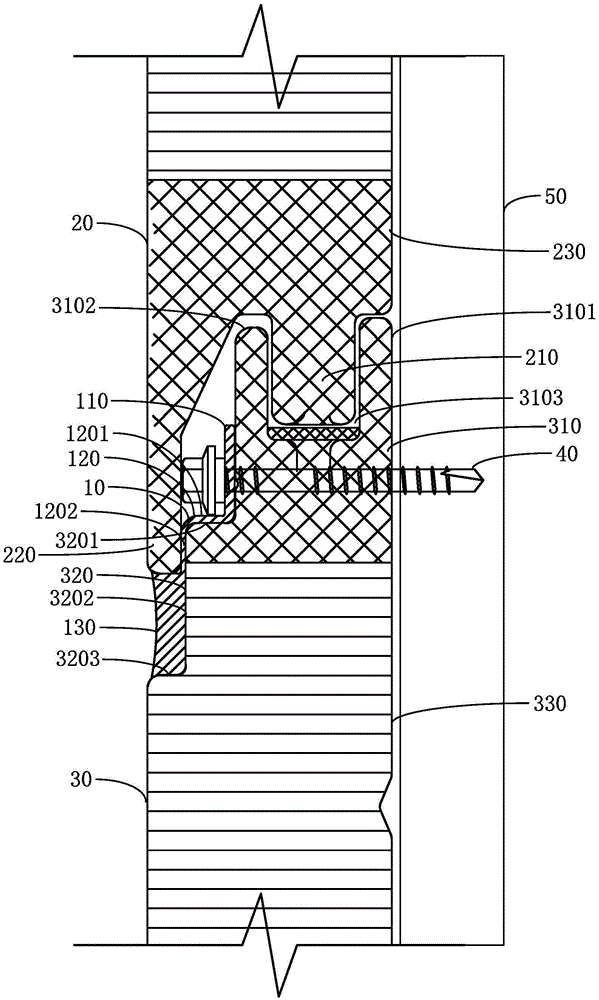

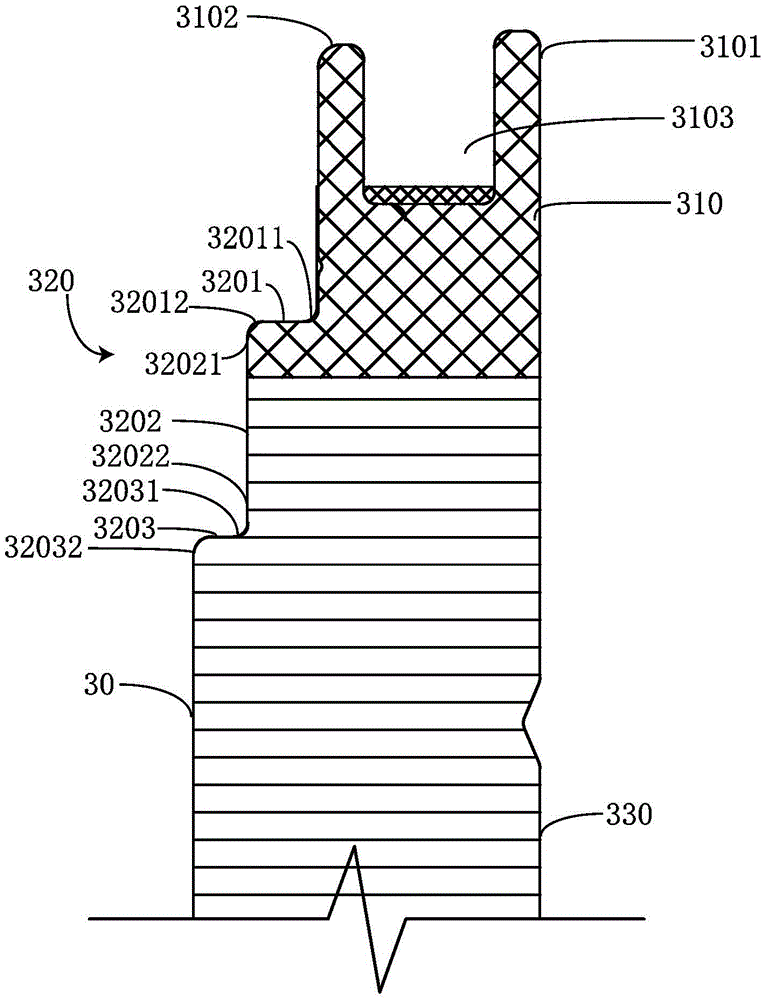

[0053] In order to solve the technical problems of the splicing method of curtain wall panels at the present stage, the thermal insulation layer breaks at the joints and easily causes cold bridges, and the joints are prone to rainwater penetration. like Figure 1-4 As shown, they are the application node structure of the sandwich panel plug-in interface rubber strip and the structural schematic diagram of the sandwich panel plug-in interface rubber strip according to the embodiment of the present invention, and the application node structure of the sandwich panel plug-in interface rubber strip includes a sandwich panel The socket strip 10 , the upper sandwich panel 20 and the lower sandwich panel 30 .

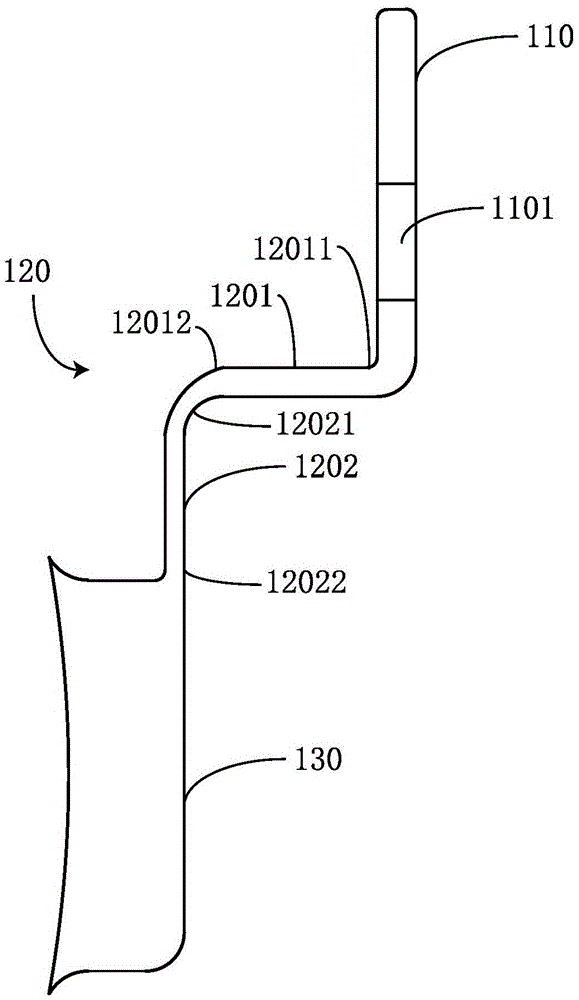

[0054] Please refer to image 3 as well as Figure 4 , are respectively a cross-sectional schematic diagram and a three-dimensional structural schematic diagram of a sandwich panel insertion interface rubber strip 10 according to an embodiment of the present invention. The sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com