type r thread

A thread and thread technology, applied in the field of fasteners, can solve the problems of large local stress, unbalanced force on thread teeth, and low repeated service life of fasteners, so as to achieve increased anti-loosening friction and good force transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

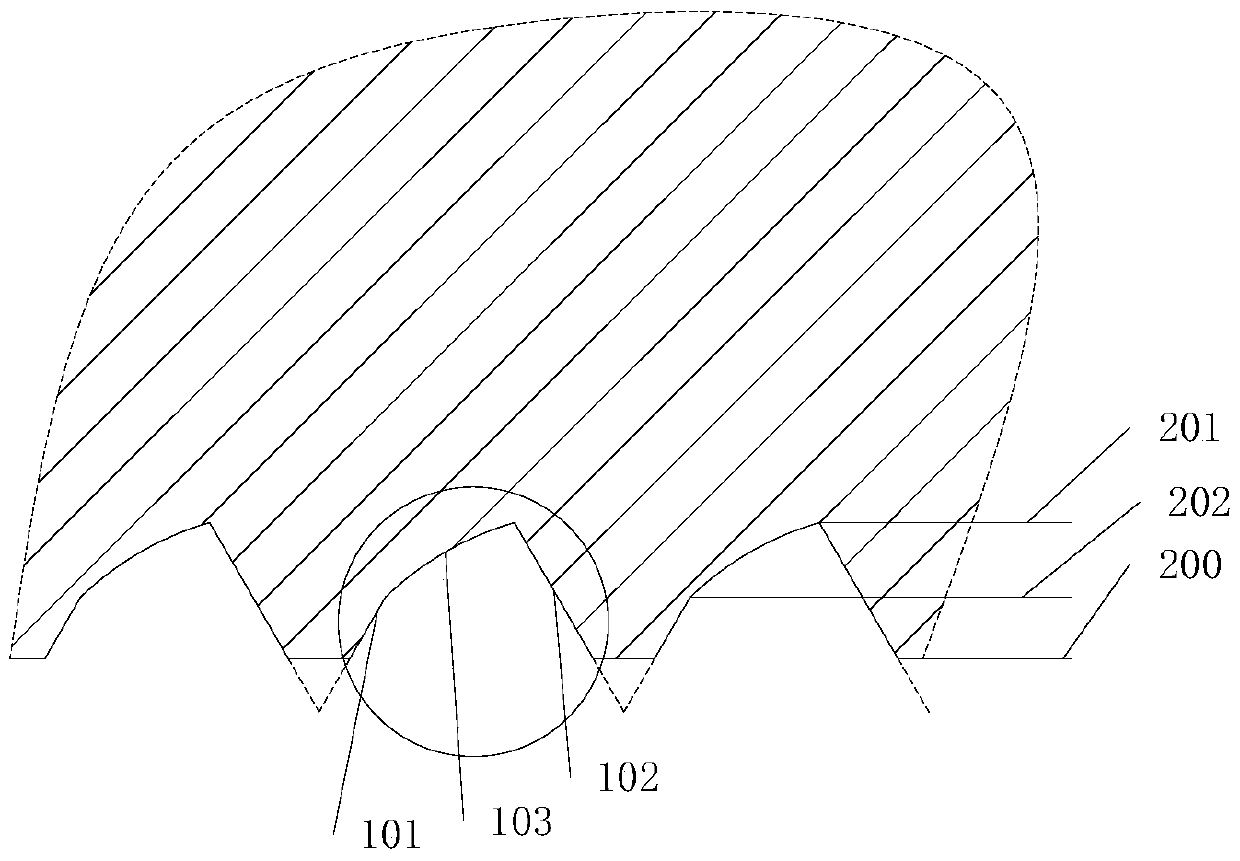

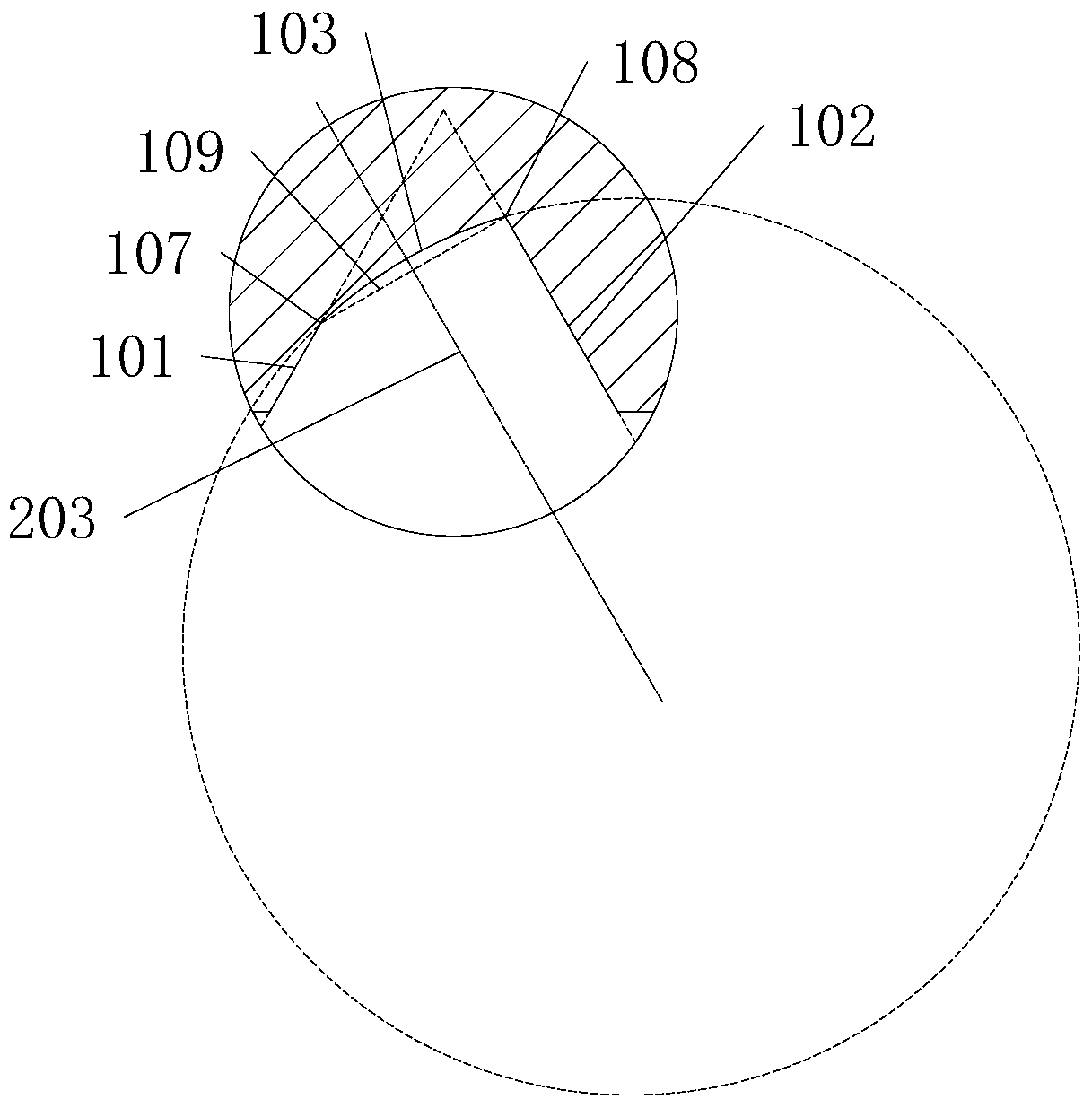

[0048] Embodiment 1, with reference to Figure 1 to Figure 3 ,as well as Figure 6 to Figure 10 .

[0049] like figure 1 and image 3 As shown, in the R-shaped thread provided by this embodiment, the two sides of the thread profile are the first lead-in side corner line 101 and the second lead-in side corner line 102, and the first lead-in side corner line 101 and the second lead-in side corner line The lines 102 are connected by a transition line 103, and the transition line 103 is recessed away from the crest.

[0050] It should be noted that: "Thread profile" determines the geometric shape of the thread, including the diameter of the workpiece (outer diameter, middle diameter and inner diameter), and the main parameters include thread profile angle, profile angle, pitch, helix angle, number of heads, etc. . "First lead-in side corner line 101" and "second lead-in side corner line 102" refer to the sides on both sides of the crest. The "transition line 103" is named "R...

Embodiment 2

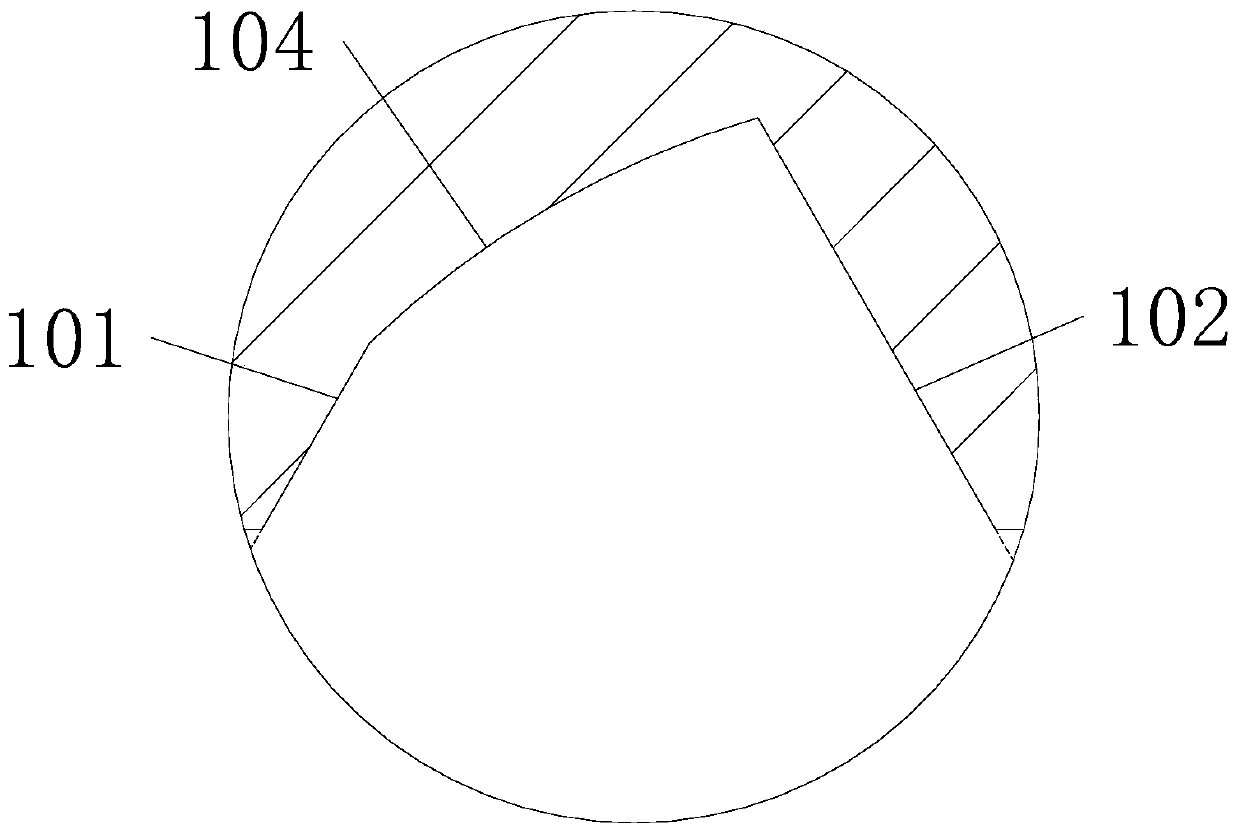

[0061] Embodiment 2, with reference to Figure 4 and Figure 5 .

[0062] like Figure 4 and Figure 5 As shown, the transition line 103 of the R-shaped thread provided by the present application can also be formed by connecting multi-segment line segments 105, and the angle range of the intersection angle between adjacent line segments is 90° to 180°. It should be noted that: here "Cross angle" means the angle towards the crest. Or it is formed by connecting multiple sections of curves 106 . The transition line 103 can be arc-shaped, and can also be formed by connecting multi-segment line segments 105, which can also achieve the effect of automatic anti-loosening. The transition line 103 is preferably an arc 104, and the effect of the transition line 103 formed by connecting multiple curves 106 is equivalent to the transition line 103 of the arc 104.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com