A smart material strain gauge for monitoring strain on asphalt pavement and its application

An alert material and asphalt pavement technology, applied in the field of road monitoring, can solve the problems of poor durability and low survival rate of monitoring components, and achieve the effects of low price, excellent alert performance and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiment:

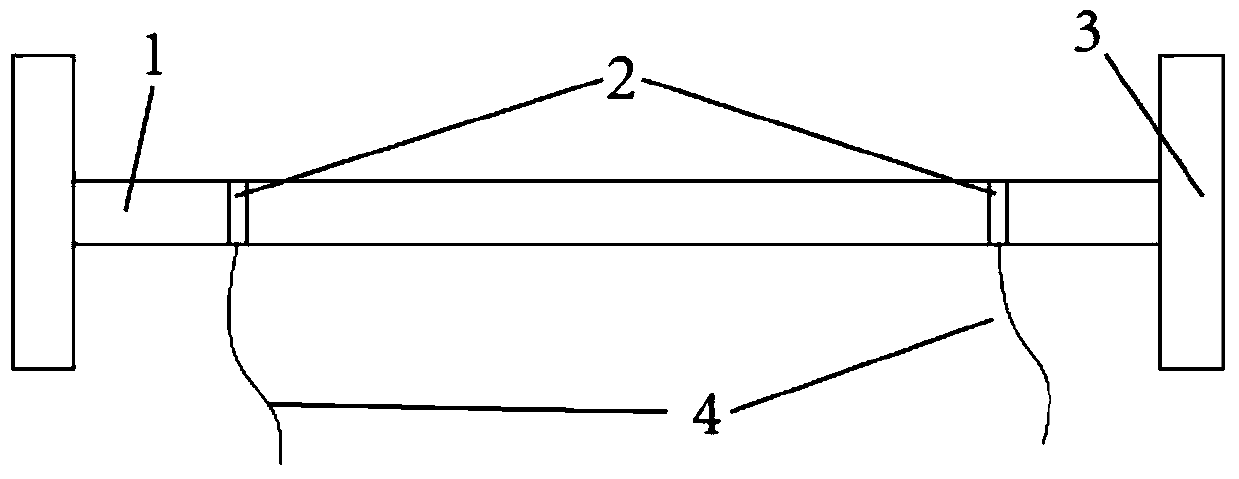

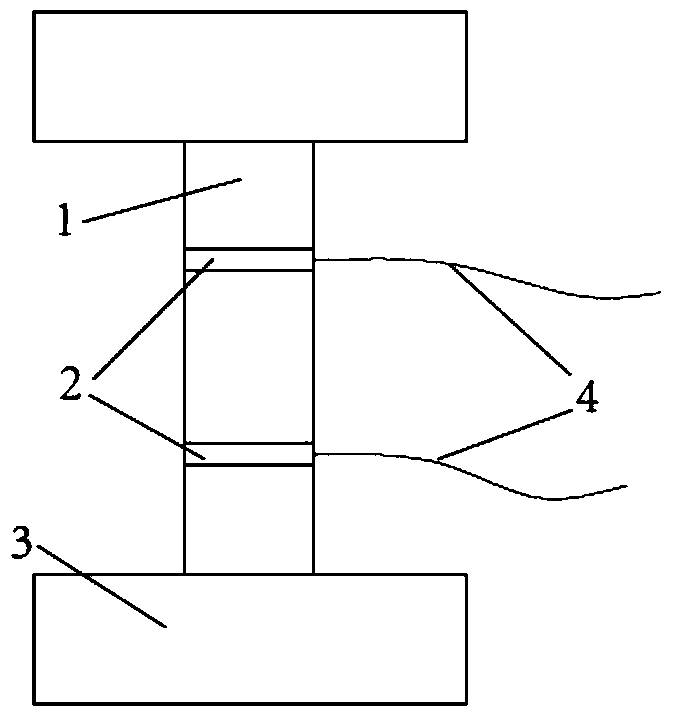

[0034] Such as figure 1 with figure 2 As shown, a sensitive material strain gauge for monitoring asphalt pavement strain includes a cylindrical bar 1, a cylindrical baffle plate 3 for fixing the cylindrical bar 1 installed at both ends of the cylindrical bar 1 respectively, and the cylindrical bar 1 is set There are several built-in electrodes 2, the cylindrical baffle 3 is made of black nylon 66, the cylindrical strip 1 is made of the nylon 66-based composite smart material, the outer side of the cylindrical strip 1 is provided with an encapsulation layer, and the built-in electrodes 2 and External line 4 is connected.

[0035] The nylon 66-based composite smart material in the two types of strain gauges is made by mixing and stirring molten nylon 66 and the conductive phase. During preparation, the black nylon 66 and the conductive phase should be fully mixed first, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com