Attitude-control engine vector thrust measurement and calibration integrated device and measurement method

A vector thrust and engine technology, applied in the calibration/testing of force/torque/power measuring instruments, measuring devices, force/torque/power measuring instruments, etc., can solve the problems of large mutual interference and large uncertainties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention will be further described below in conjunction with accompanying drawing:

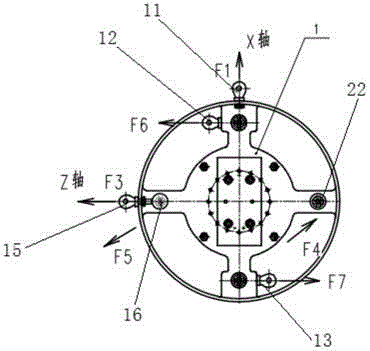

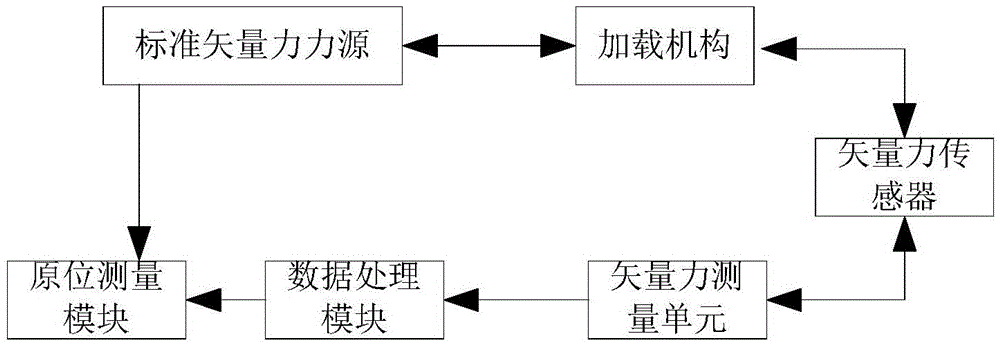

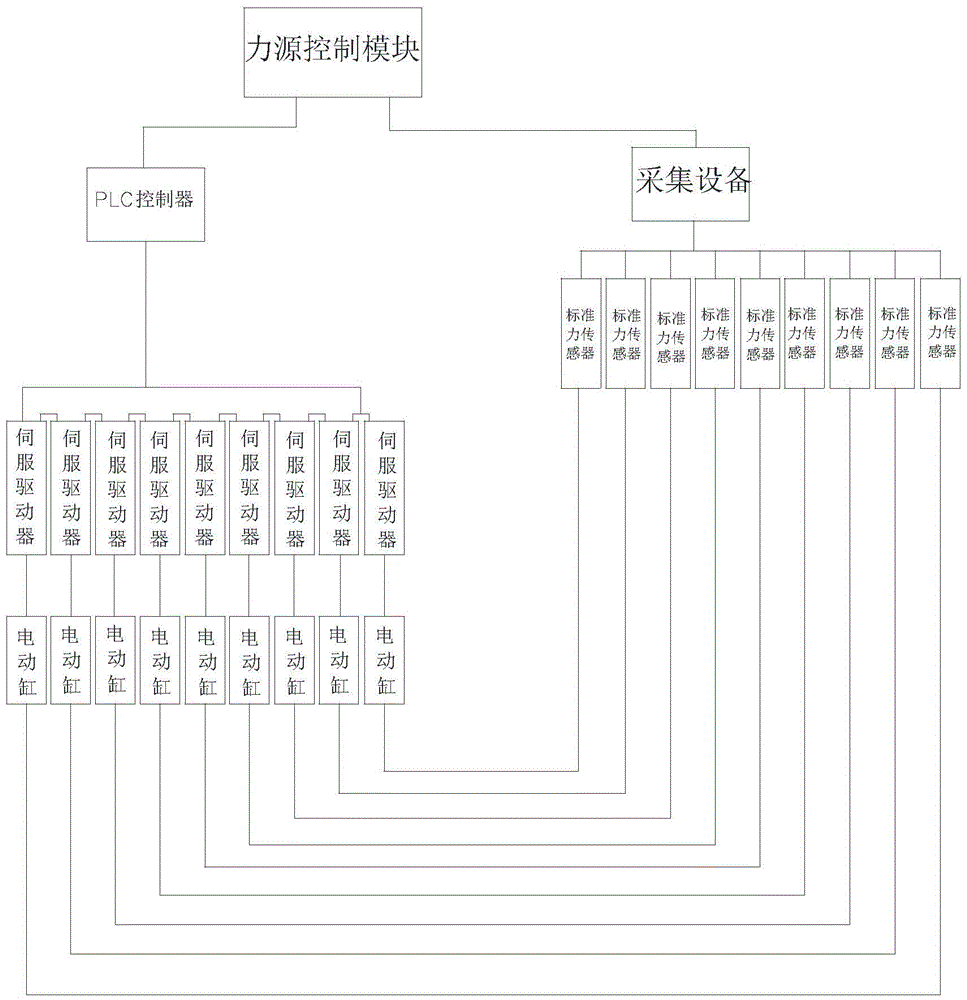

[0101] The attitude control engine vector thrust measurement and calibration integrated device is used as the main means for attitude control engine vector thrust acquisition. It is characterized in that: the device consists of two parts: vector thrust measurement device and vector thrust in-situ calibration device; During the working process of the attitude control engine, the vector thrust is measured; the measurement range of the main thrust Fx is 0-2000N, the lateral force Fy and Fz are 0-60N, the X-axis moment Mx is 0-20N·m, and the Y-axis moment My is 0 ~10N·m, Z-axis moment Mz is 0~50N·m; its axial thrust static measurement expanded uncertainty is 0.5% (k=2), lateral thrust static measurement expanded uncertainty is 2% (k= 2) Expanded uncertainty of torque static measurement: 2% (k=2); vector thrust in-situ calibration device can perform in-situ calibration on the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com