Performance testing system and method for thermoelectric refrigeration device

A technology of thermoelectric refrigeration and testing system, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., to achieve the effects of strong simulation reproducibility and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

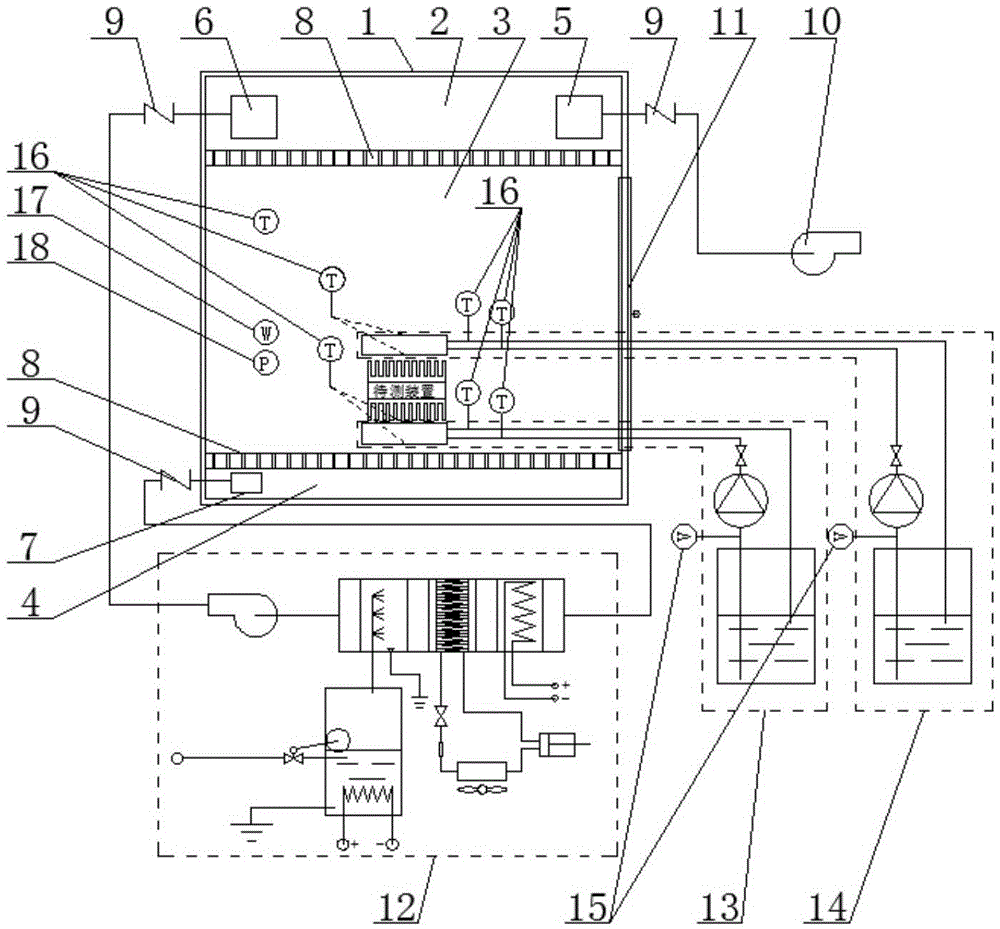

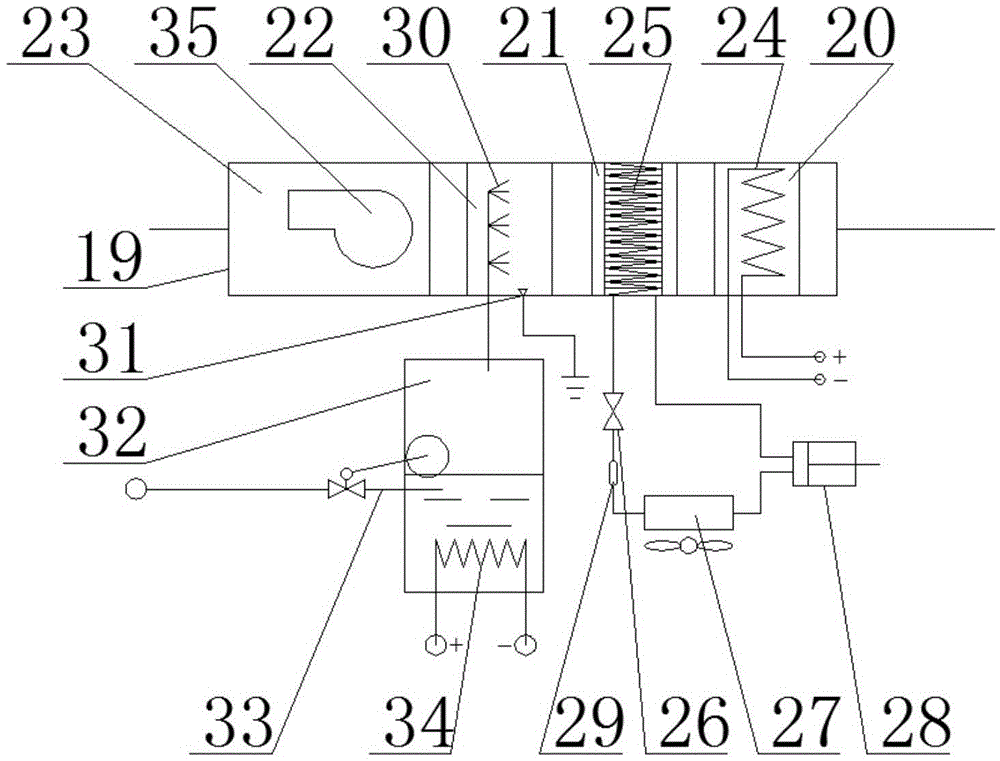

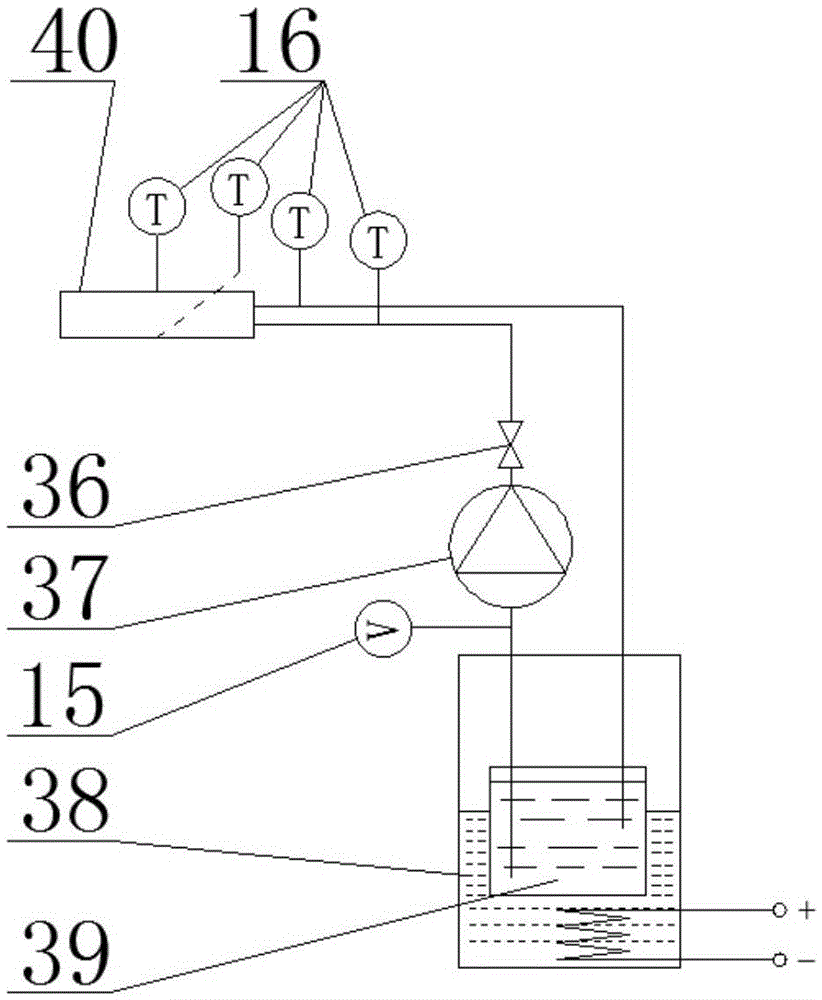

[0050] Such as figure 1 As shown, a thermoelectric refrigeration device performance testing system provided by the present invention includes a test chamber 1, a temperature and humidity control device 12, a vacuum pump 10, a hot end calorimetric module 13, a cold end calorimetric module 14, a data acquisition module, Automatic control module, power supply module, etc.

[0051] The upper and lower parts of the test chamber 1 are respectively provided with orifice plates 8 , which divide the test chamber 1 into three layers: a pressure stabilization layer 2 , a test layer 3 and an air return layer 4 . The orifice plate 8 is a flat plate with evenly distributed communicating holes, which plays the role of uniform air supply. The voltage stabilizing layer 2 is provided with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com