Tool and instrument period management method

A cycle management and tool technology, applied in the field of management, can solve the problems of incapable tool usage and life monitoring, time-consuming and labor-intensive, and achieve the effect of solving time-consuming and labor-intensive, simple operation, and realizing monitoring and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

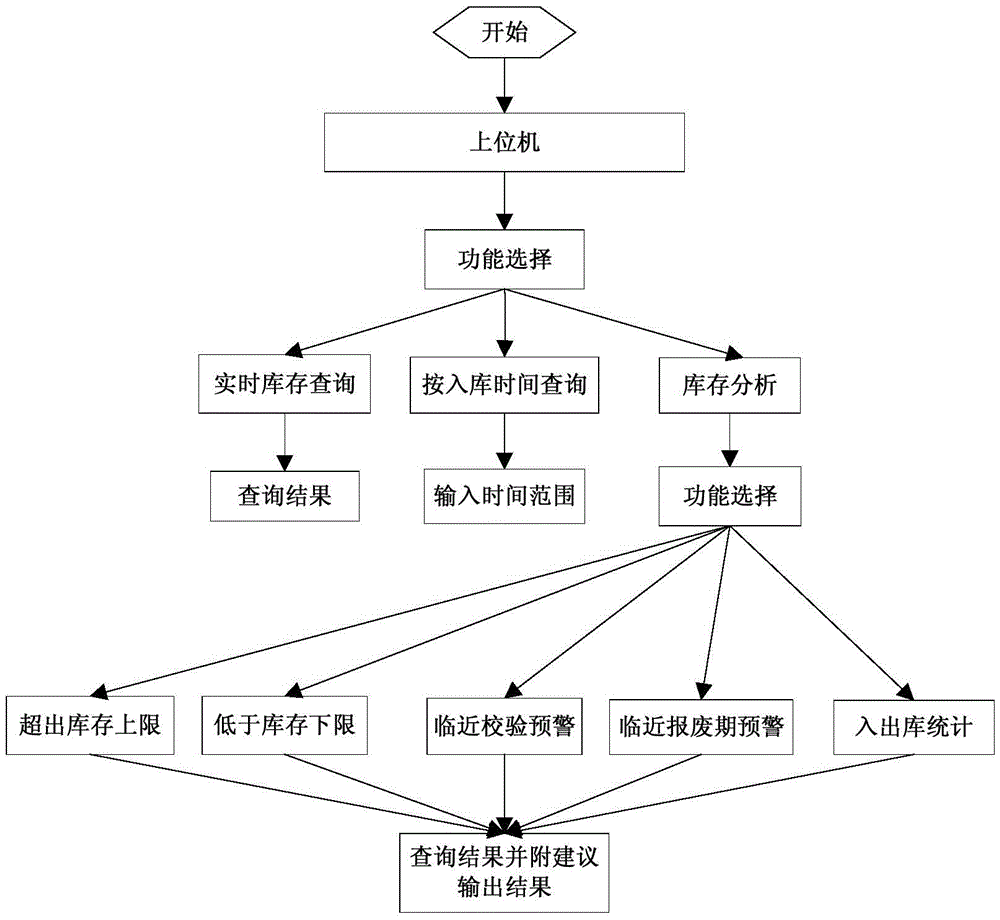

[0017] refer to figure 1 , the tool cycle management method described in the present invention includes tool storage and delivery, inventory query and scrap verification and early warning;

[0018] The warehousing and warehousing of the tools and utensils includes the following steps: paste the corresponding barcodes on the tools and utensils to be put into the warehouse, scan the bar codes on the tools and utensils to be put into the warehouse, record the time of putting in the tools and utensils to be put into the warehouse, When in storage, scan the barcode on the tool to be delivered, record the time of delivery of the tool to be delivered, and establish a database corresponding to the type, storage time and delivery time of each tool;

[0019] The inventory query includes real-time inventory query, query by storage time, and query by tool. The query by tool inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com