Manufacturing method of LED light bars

A manufacturing method and LED substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low production efficiency, complex production process with lights, high production cost, etc., to improve production efficiency, facilitate automatic production, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

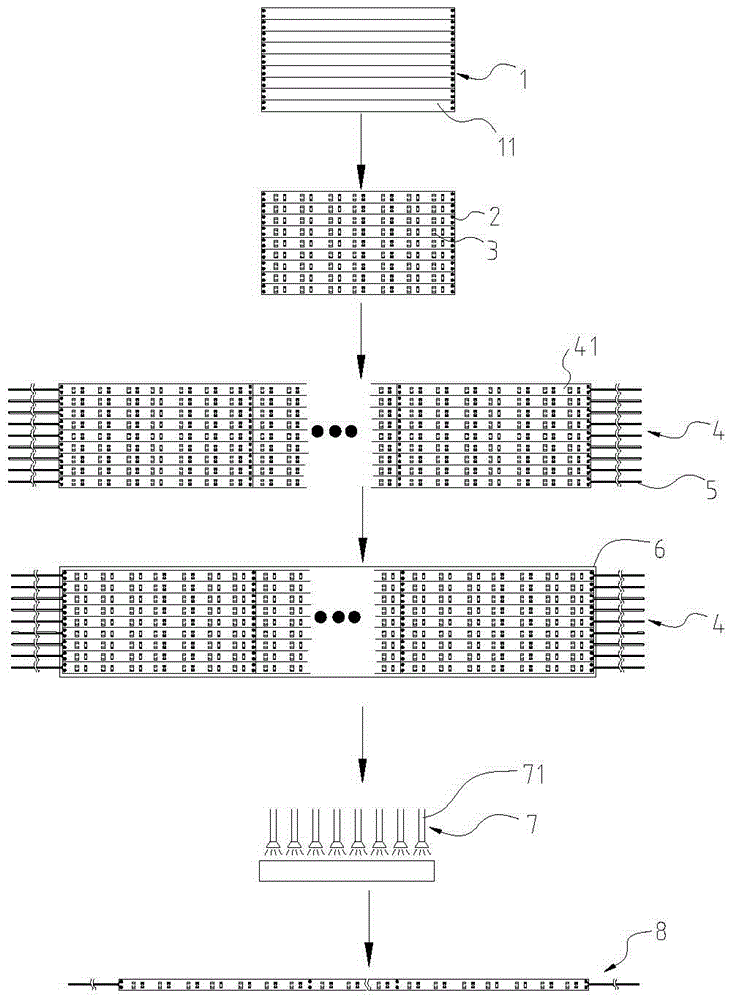

[0028] The present invention will be further described below in conjunction with the accompanying drawings of the description.

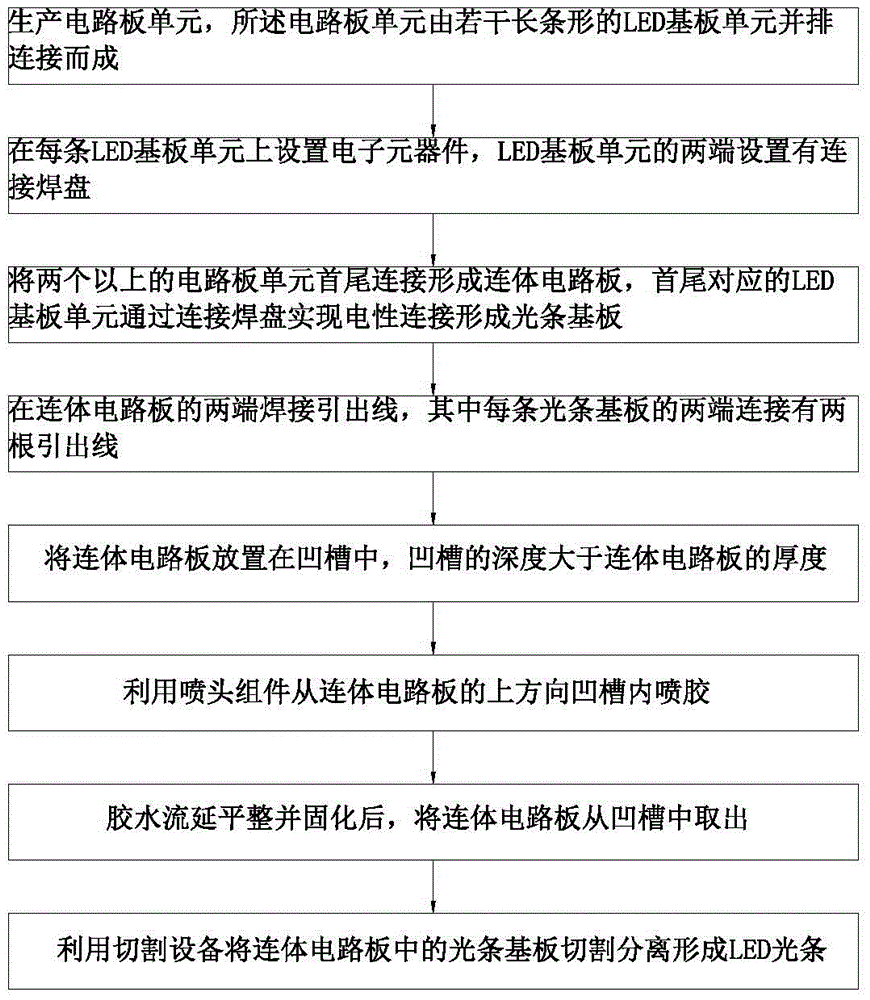

[0029] Such as figure 1 , 2 Shown, a kind of manufacturing method of LED light bar, comprises the following steps:

[0030] (1) Produce circuit board unit 1, said circuit board unit 1 is formed by connecting several strip-shaped LED substrate units 11 side by side; the circuit board unit 1 of this embodiment is a flexible circuit board, and said circuit board unit 1 It is rectangular and can be set according to requirements. The more LED substrate units 11 contained, the larger the area of the circuit board unit 1; in this embodiment, there are 9 LED substrate units 11 in total, and the length of the circuit board unit 1 is 50cm, and the width 24cm;

[0031] (2) Electronic components are arranged on each LED substrate unit 11, the electronic components include resistors and LED chips 3, and connection pads 2 are provided at both ends of the LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com