Safety fireproof cooling wiring conduit

A wiring wire and wire pipe technology, which is applied in the field of safe fire prevention and heat dissipation wiring wire and pipe, can solve the problems of wire damage, fire, and inability to dissipate heat from wires, and achieve the effects of avoiding damage, preventing fire problems, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

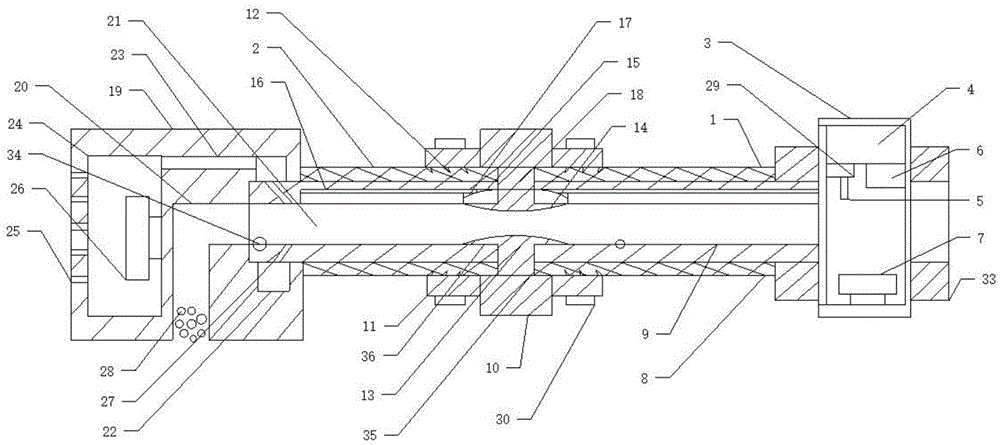

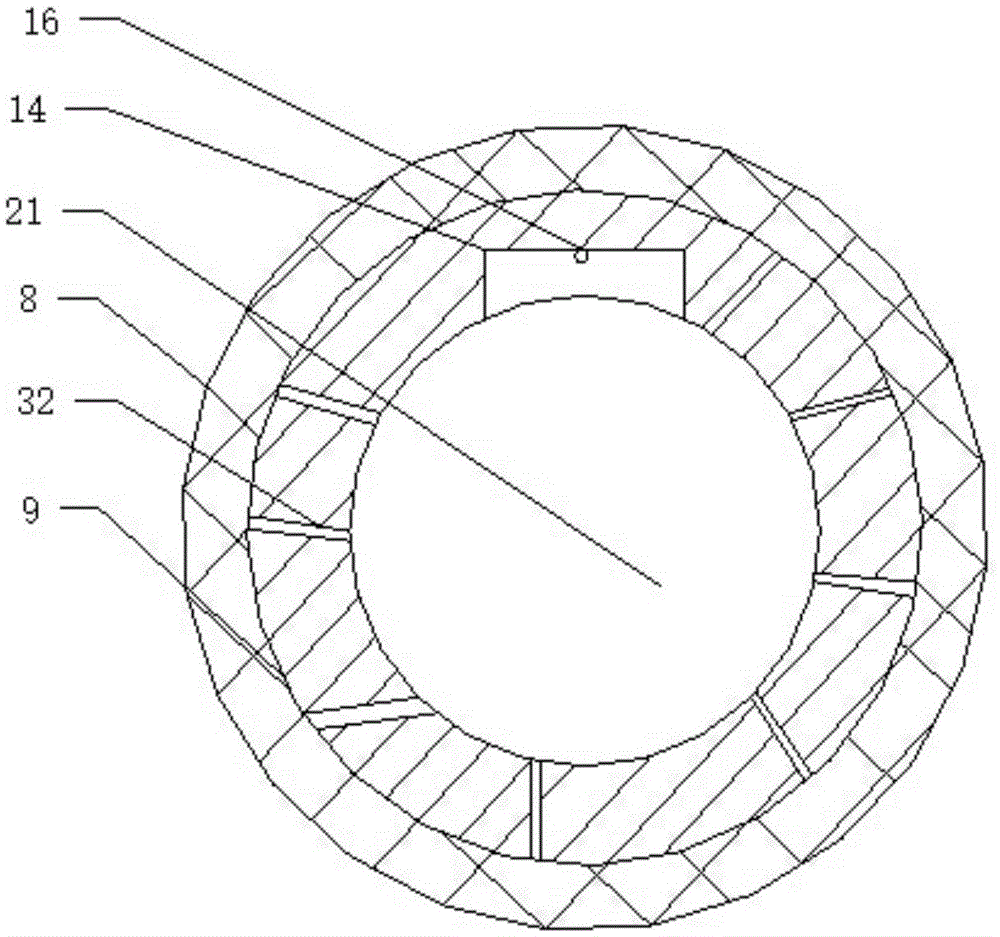

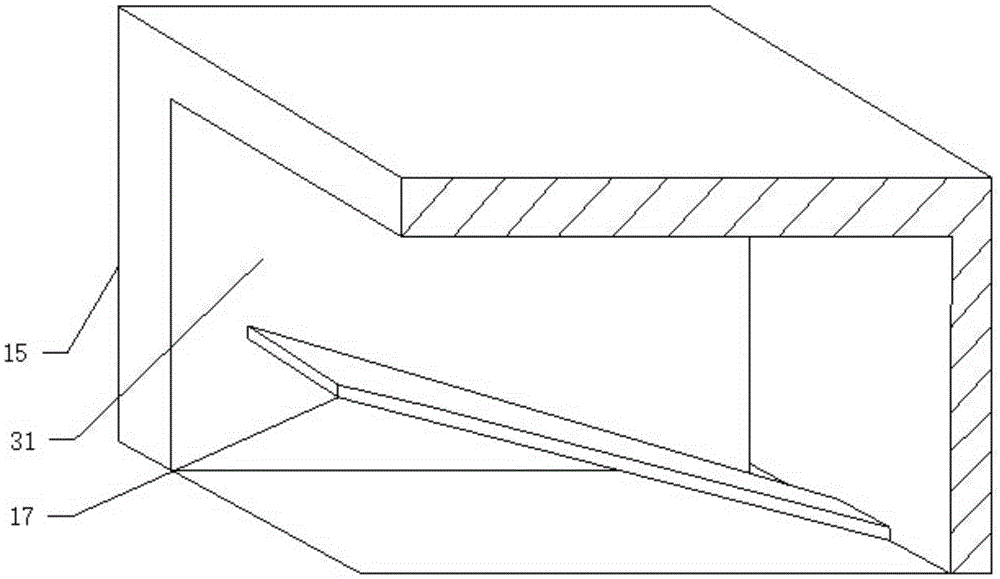

[0029] Such as figure 1 As shown, a safe, fire-proof and heat-dissipating wiring conduit includes a cable conduit 1, a cable conduit 2 and a connecting plug 10 connecting the cable conduit 1 and the cable conduit 2, the cable conduit 1 and the cable conduit 2 Each includes a cable body 9 and a protective cooling layer 8 arranged on the outer ring of the cable body 9 .

[0030] Such as figure 2 As shown, the wire tube body 9 is covered with cooling holes 32 communicating with the wire barrel 21 and the protective cooling layer 8 .

[0031] Wherein the protective cooling layer 8 is a mixed weaving of copper and stainless steel and is in the shape of a grid.

[0032] A large amount of heat will be generated during the electrification process of the electric wire, so the heat generated by the electric wire will be dissipated to the outer wall of the wire pipe body 9 and then be distributed into the air by the outer wall of the wire pipe body 9, and the wire pipe body 9 is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com