Reciprocating saw mechanism

A technology of reciprocating saws and reciprocating rods, which is applied in the field of reciprocating saws and can solve problems such as faults and power reduction of reciprocating saws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

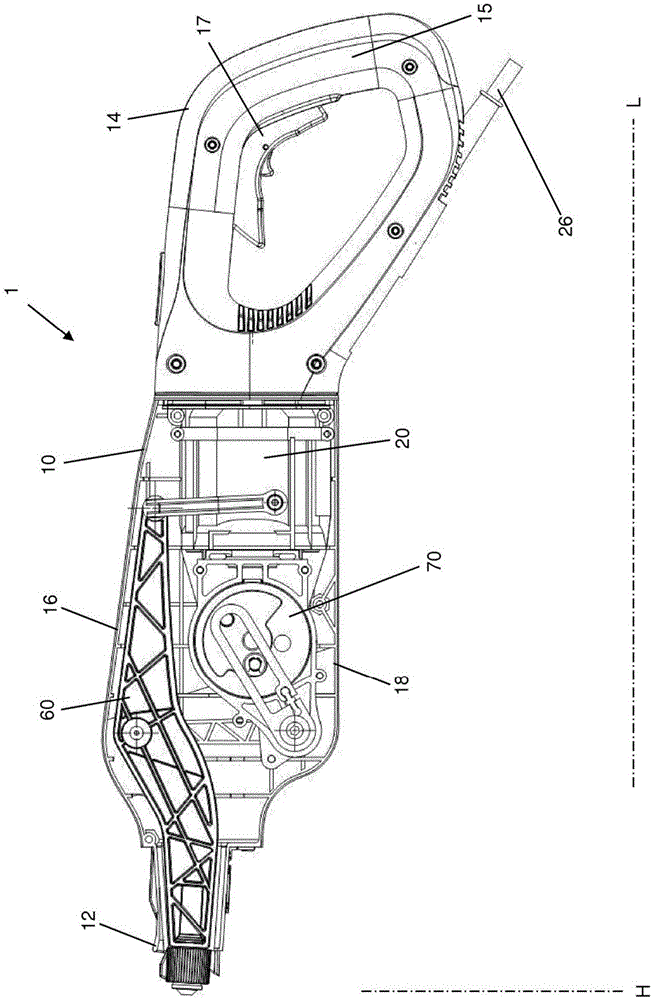

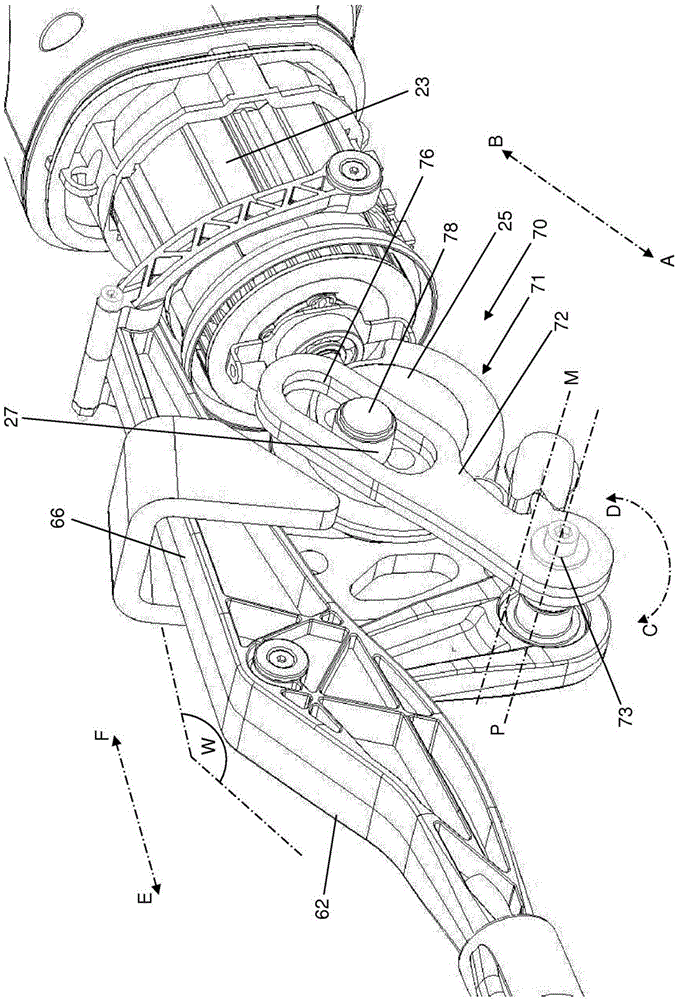

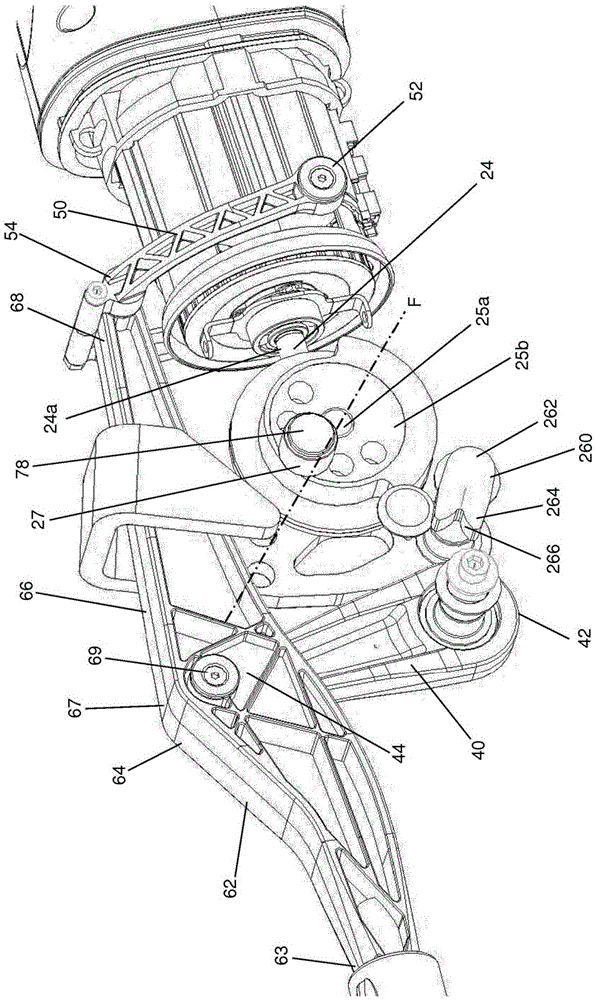

[0037] Figures 1 to 10 A first embodiment of a reciprocating saw 1 according to the invention is shown, which basically comprises a reciprocating saw housing 10, a drive 20, a first articulation rod 40, a second articulation rod 50, a reciprocating rod 60, a connecting device 70, A saw, not shown, and a control, not shown.

[0038] The reciprocating saw housing 10 has a first housing end 12 , a second housing end 14 , a housing top side 16 and a housing bottom side 18 . The saw is positioned on a first housing end 12 and has a handle 15 with a switch member 17 on a second housing end 14 . The drive 20 , the first articulated rod 40 , the second articulated rod 50 , the reciprocating rod 60 and the control are at least partially housed in the reciprocating saw housing 10 .

[0039] The driver 20 includes a driver housing 22 , an electric motor 23 including a drive shaft 24 and a drive wheel 25 , and an energy supply 26 . The electric motor 23 can be a DC motor or an AC moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com