Composite molded product and method for manufacturing same

A manufacturing method and composite molding technology, which can be applied to layered products, other household appliances, conductive adhesive connections, etc., can solve the problems of time-consuming, difficult to volatilize solvents, dissolution of base film or abnormal swelling and appearance, etc. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0070] Below, use figure 1 and even Figure 7 The composite molded product and its manufacturing method according to the first embodiment of the present invention will be described.

[0071] (1) Overview of composite molded products

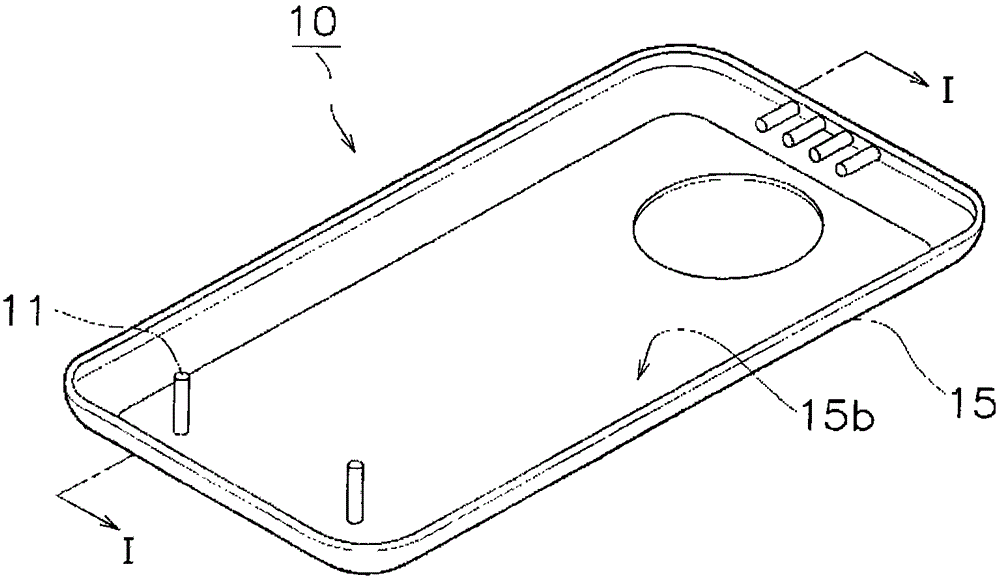

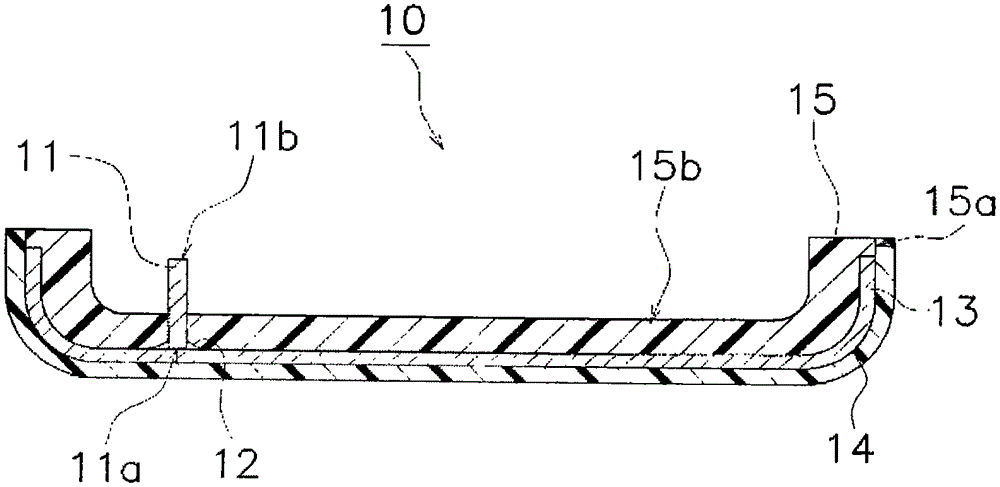

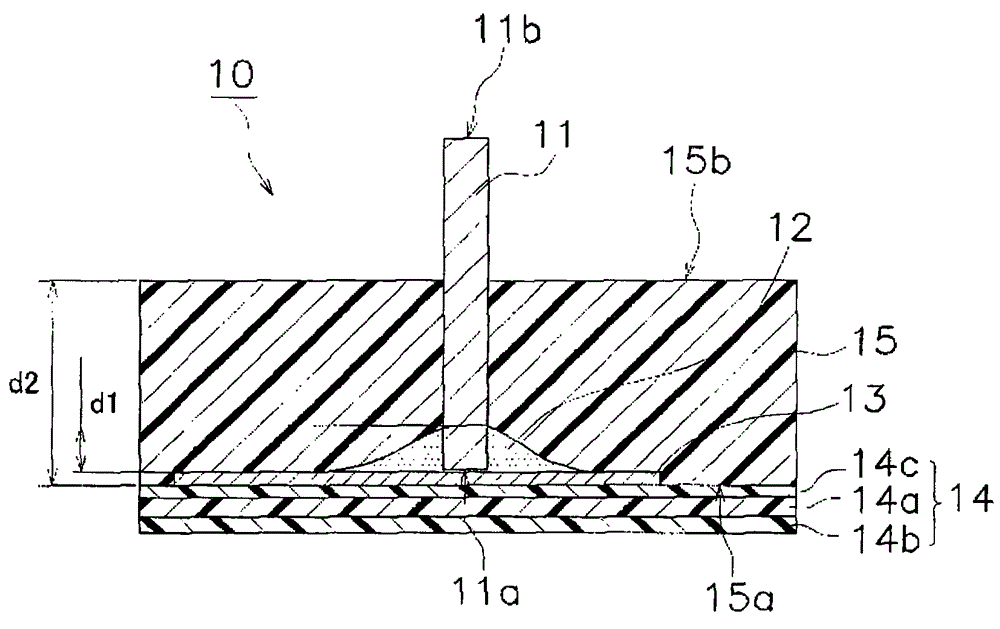

[0072] figure 1 It is a perspective view for explaining the outline of the structure of the composite molded article which concerns on 1st Embodiment of this invention. figure 2 for along figure 1 Cross-sectional view of the I-I line. In addition, in image 3 in, zoomed in on figure 2 The periphery of the connection portion of the contact pin and the electrode pattern layer in the cross-sectional configuration shown in .

[0073] figure 1 and even image 3 A composite molded product 10 shown in , includes a contact pin 11 , a conductive adhesive 12 , an electrode pattern layer 13 , a transfer layer 14 , and a molded body 15 . The molded body 15 has a structure obtained by molding a thermoplastic resin by injection molding described la...

no. 2 approach

[0103] (4) Overview of composite molded products

[0104] Next, use Figure 8 and even Figure 10 A composite molded article according to a second embodiment of the invention will be described. Figure 8 A composite molded product 10A according to the second embodiment is shown, Figure 9 (a) shows the contact pin 11F used for the composite molded product 10A. Figure 10 (a) means along Figure 8 The section of line II-II, Figure 10 (b) shows a section along line III-III. The composite molded product 10A according to the second embodiment differs from the composite molded product 10 according to the first embodiment in that the shape of the contact pin 11F is a flat plate extending in a strip shape; This point supports the protrusion 16 and the rib 17 . Since the composite molded product 10A according to the second embodiment has the same basic structure as the composite molded product 10 according to the first embodiment, the composite molded product 10A will be descr...

no. 3 approach

[0118] (6) Overview of composite molded products

[0119] In the composite molded articles 10 and 10A according to the first and second embodiments described above, the contact pins 11 and 11F are exposed on the side opposite to the electrode pattern layer 13 and the transfer layer 14 . However, the direction in which the contact pins are exposed may be the opposite side to the composite molded product 10, 10A. For example, the electrode pattern layer 13 may have a structure through which contact pins penetrate.

[0120] Figure 11 The composite molded product 10B according to the third embodiment shown has a structure in which contact pins 11F penetrate through the electrode pattern layer 13 . Figure 11 The contact pin 11F shown is used as Figure 10 (a) As already described, the opening 11Fc is formed in the one end 11Fa and the other end 11Fb.

[0121] The other end 11Fb of the contact pin 11F penetrates not only the electrode pattern layer 13 but also the conductive a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com