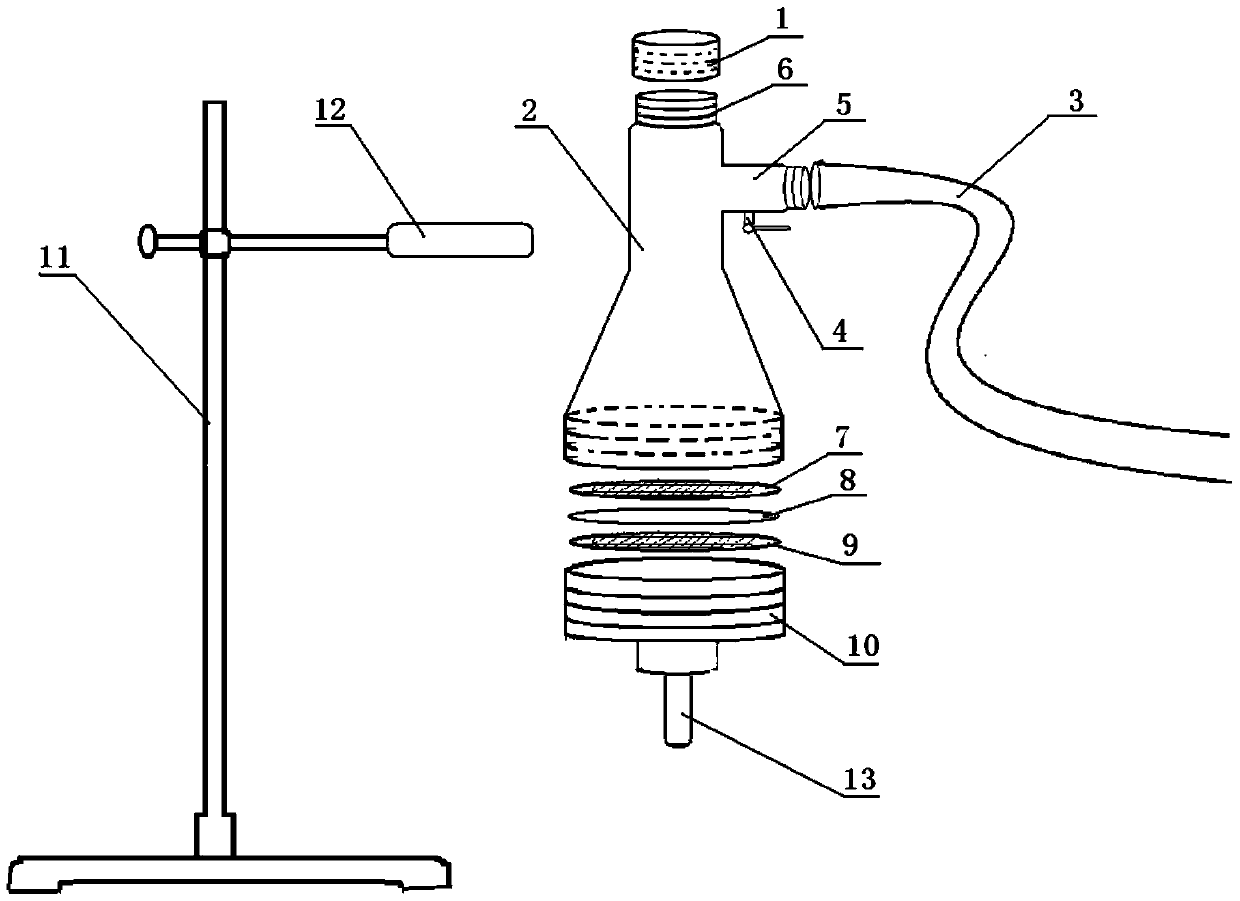

Liposome High Pressure Extrusion Filtration Device

A filter device and body high pressure technology, applied in the field of biomedicine, can solve problems such as difficulty in meeting laboratory preparation requirements, insufficient extrusion of liposome samples, cumbersome multiple continuous extrusion operations, etc., to achieve unique convenience and Effectiveness, ease of high-temperature sterilization, convenience and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

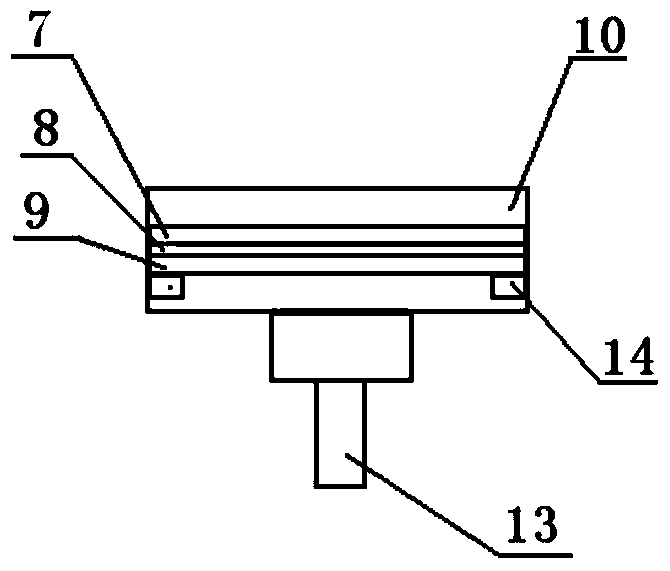

Method used

Image

Examples

Embodiment 1

[0040] Take 60 mg of dry phospholipids and 9 mg of cholesterol, dissolve them in 10 mL of chloroform, and then rotate to evaporate to form a lipid film, add 5 mL of phosphate buffer (pH 7.4) and shake by hand to form liposomes with different particle sizes. At 3-30μm (see image 3 ). Afterwards, the liposome suspension was added to the liposome high-pressure extrusion filtration device of the present invention, and after 10 times of extrusion and filtration, a liposome suspension with a particle size of about 1 μm and a relatively uniform particle size distribution was obtained (see Figure 4 ).

Embodiment 2

[0042] The liposomes are high-pressured out of the various components of the filter device (except the filter device holder 11 and the clip 12), autoclaved in an autoclave, taken out and dried, and then assembled in a sterile environment. Then, the viscous collagen swelling solution is added to the extrusion filtration device, and the sterile collagen swelling solution can be obtained after squeezing and filtering (the filter membrane is a polyethersulfone filter with a pore size of 0.22 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com