A pass-through double-toothed roller crusher with side tooth plate installation and adjustment device and its adjustment method

A technology for installing adjustment and adjustment devices, applied in the direction of grain processing, etc., can solve the problems of equipment selection cost, operation cost and accessories supply cost increase, inability to add material classification equipment, and narrow crushing site space, etc., to achieve simple structure and rigidity. Good, short adjustment period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

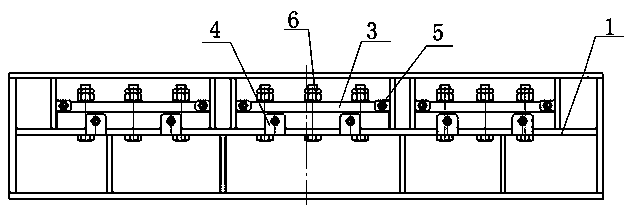

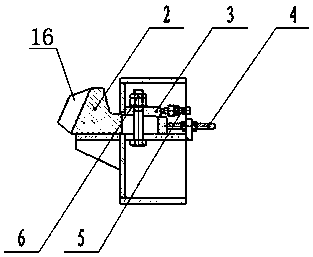

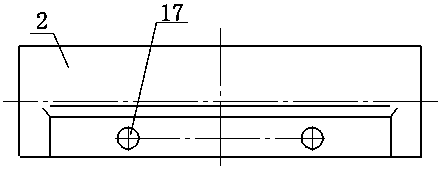

[0035] A through-type double-toothed roller crusher with a side tooth plate installation adjustment device, including: a box body, a side tooth plate, a crushing roller 7, a bearing seat 9, a coupling 10, a power mechanism and a side tooth plate adjustment device 8, a box A pair of outwardly turning crushing rollers 7 are arranged in parallel in the body, side tooth plates matching the crushing rollers are arranged on the side wall of the box body, and the crushing rollers 7 are connected with the power mechanism through bearing housings 9 and couplings 10; It is the fixed side tooth plate 15, the lower part is the movable side tooth plate 2, the movable side tooth plate 2 is close to the crushing roller 7, the fixed side tooth plate 15 extends obliquely above the movable side tooth plate 2 away from the crushing roller 7; the movable side tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com