Anchor chain spray nozzle

A nozzle and anchor chain technology, applied in the direction of jetting devices, etc., can solve the problems of fixed nozzles not being able to adjust the angle at will, delay in the construction cycle of ships, and large workload, etc., to achieve good flushing effect, reduce rework, and accurately adjust the water output effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

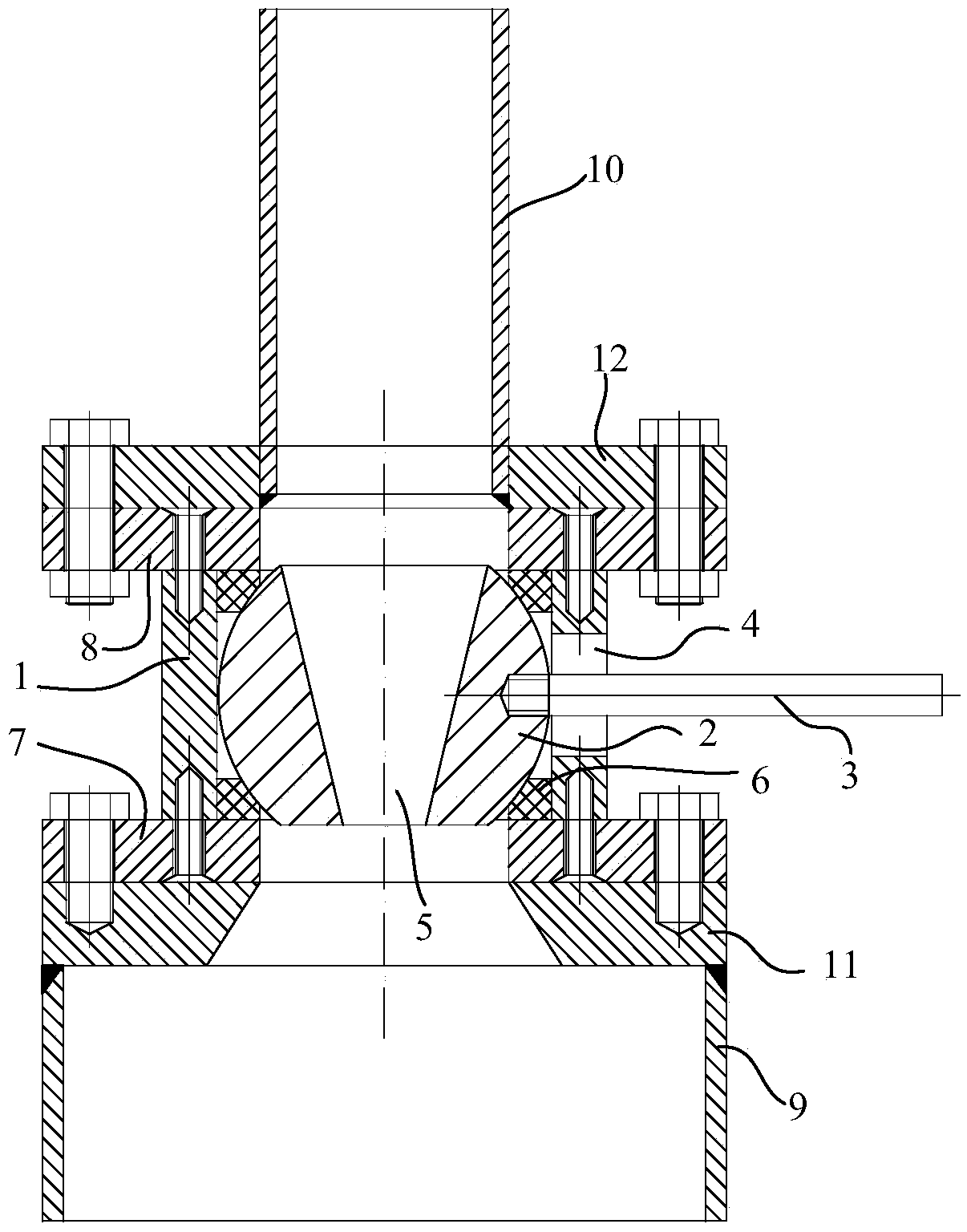

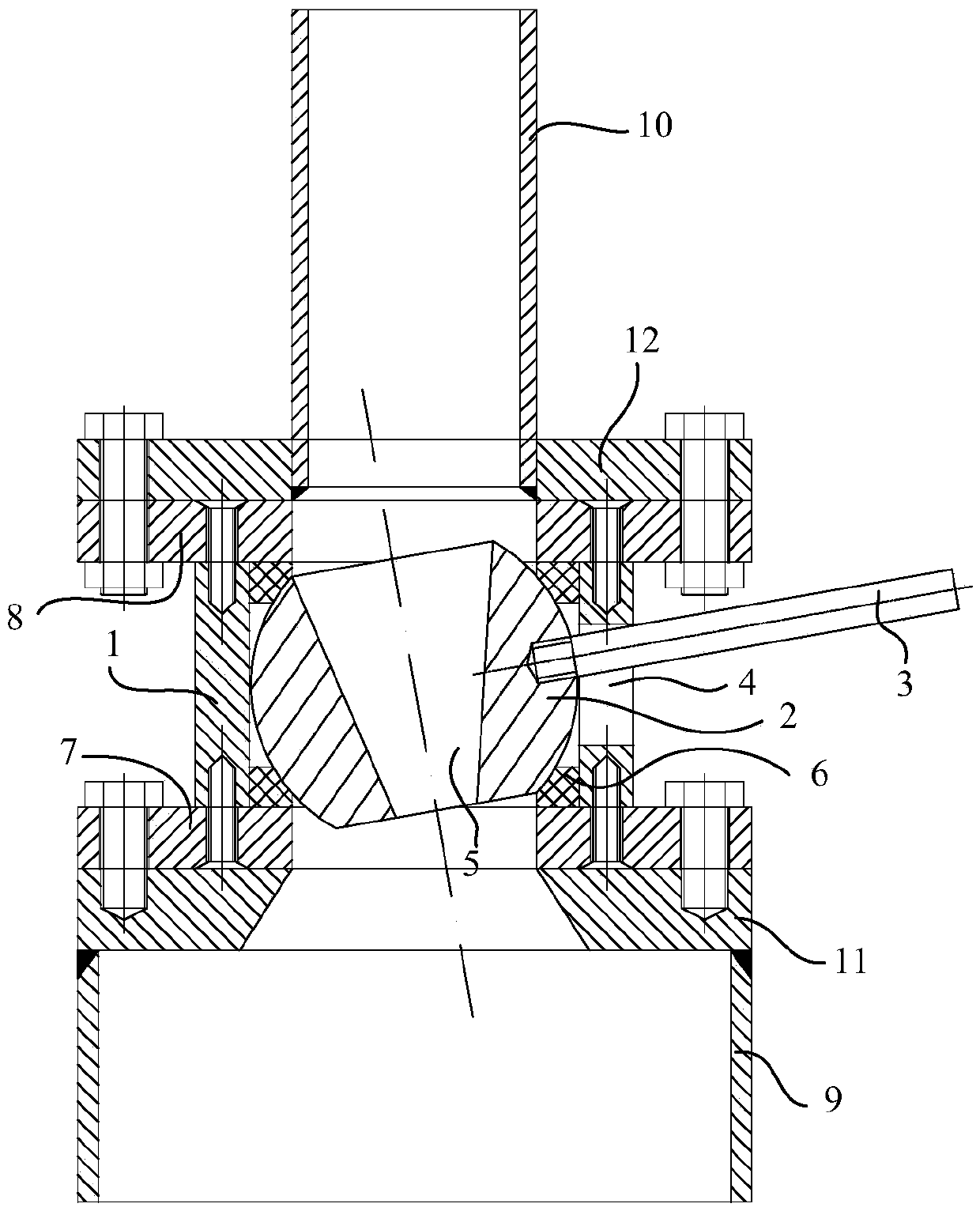

[0024] An anchor chain nozzle, comprising a casing 1 and a water inlet pipe 10 communicating with the casing 1, a nozzle 2 is arranged inside the casing 1, a handle 3 is fixed on the nozzle 2, the handle 3 extends through the casing 1 to the outside of the casing 1, and the nozzle 2 Move under the drive of the handle 3 to adjust the water outlet angle of the nozzle 2. Such as figure 1 As shown, the handle 3 can swing in the up and down direction, and can also swing in the front and rear directions, not only the water outlet direction of the nozzle 2 can be adjusted, but also the water outlet angle of the nozzle 2 can be adjusted, the water outlet adjustment of the nozzle 2 is more accurate, and the flushing effect is better. , reducing rework. Up and down, front and back are for clarity of description, and refer to figure 1 display in .

[0025] Specifically, the shell 1 is provided with a through hole 4, the handle 3 passes through the shell 1 through the through hole 4, t...

Embodiment 2

[0033] This embodiment is basically similar in structure to the anchor chain nozzle of Embodiment 1, including a casing 1 and a water inlet pipe 10 communicating with the casing 1. A nozzle 2 is arranged inside the casing 1, and a handle 3 is fixed on the nozzle 2, and the handle 3 passes through The casing 1 extends out of the casing 1, and the handle 3 can swing around a straight line parallel to the water inlet direction, and can also swing around a straight line perpendicular to the water inlet direction.

[0034] The difference is that the specific structure of the nozzle 2 is not limited, the specific structure of the housing 1 is not limited, and the specific positional relationship between the handle 3 and the housing 1 is not limited, as long as the water outlet direction and the water outlet angle can be adjusted simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com