On-line steel tube detecting and sorting device

A sorting device and steel pipe technology, applied in sorting and other directions, can solve the problems of reducing production efficiency, affecting production efficiency, secondary damage to steel pipes, etc., and achieve the effects of improving work efficiency, fast detection speed, and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

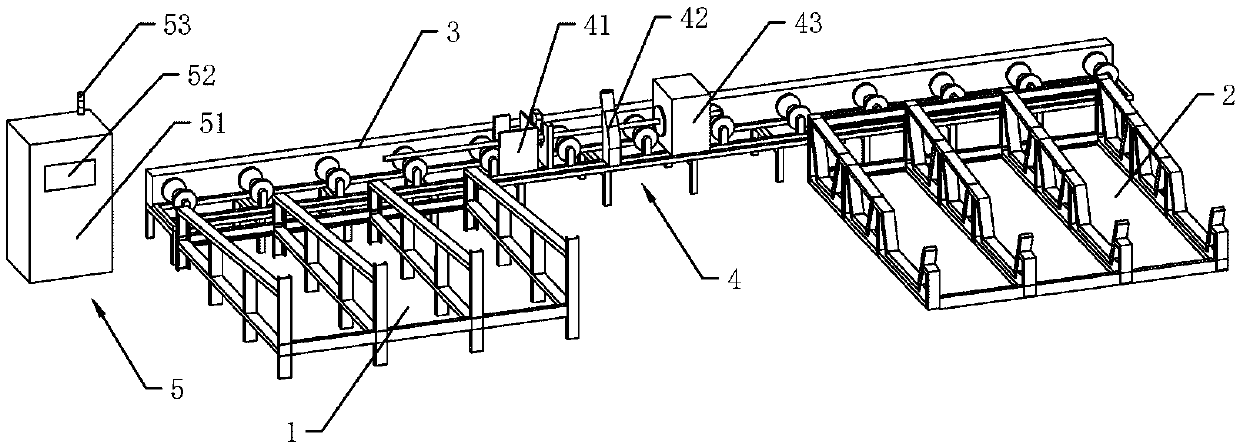

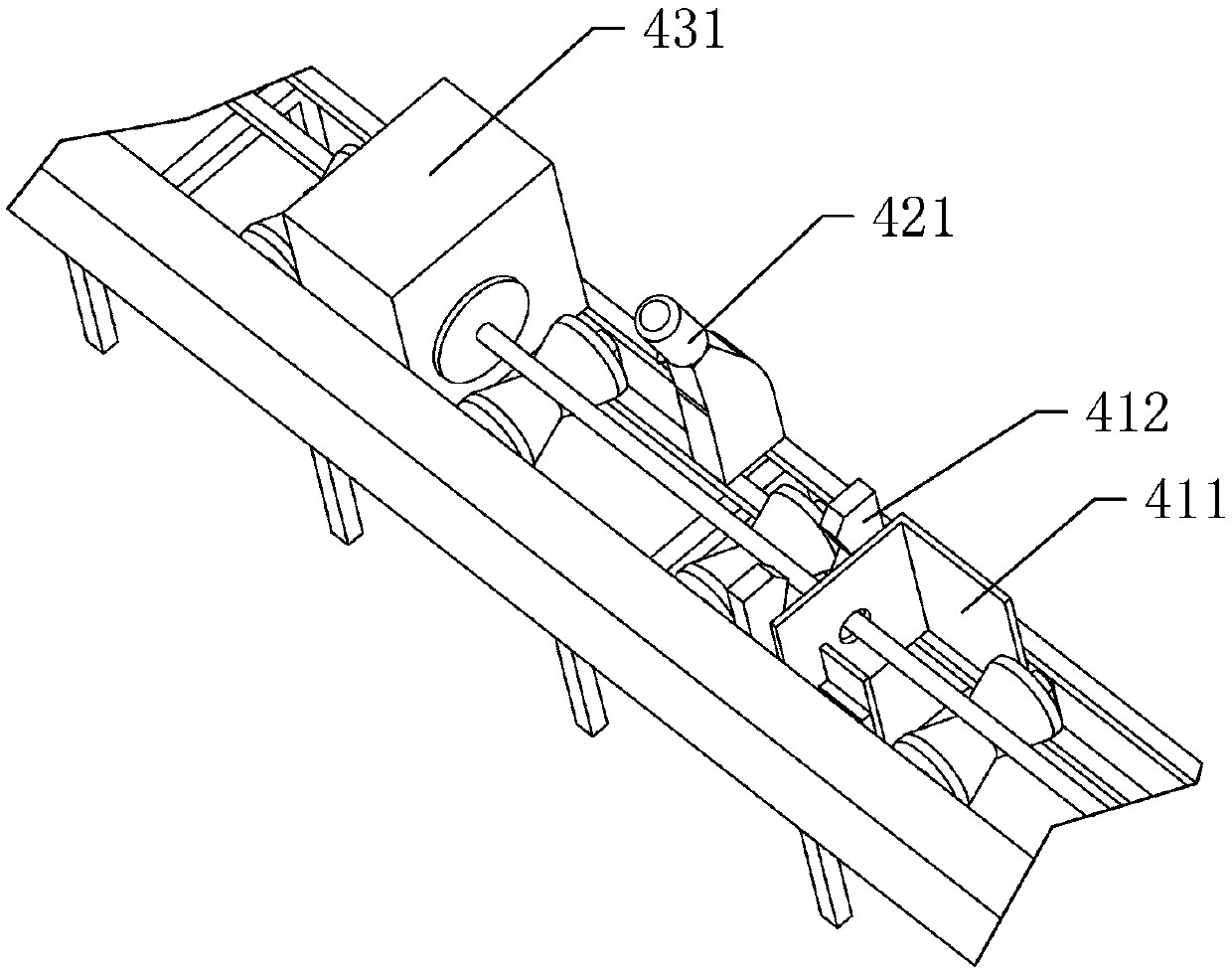

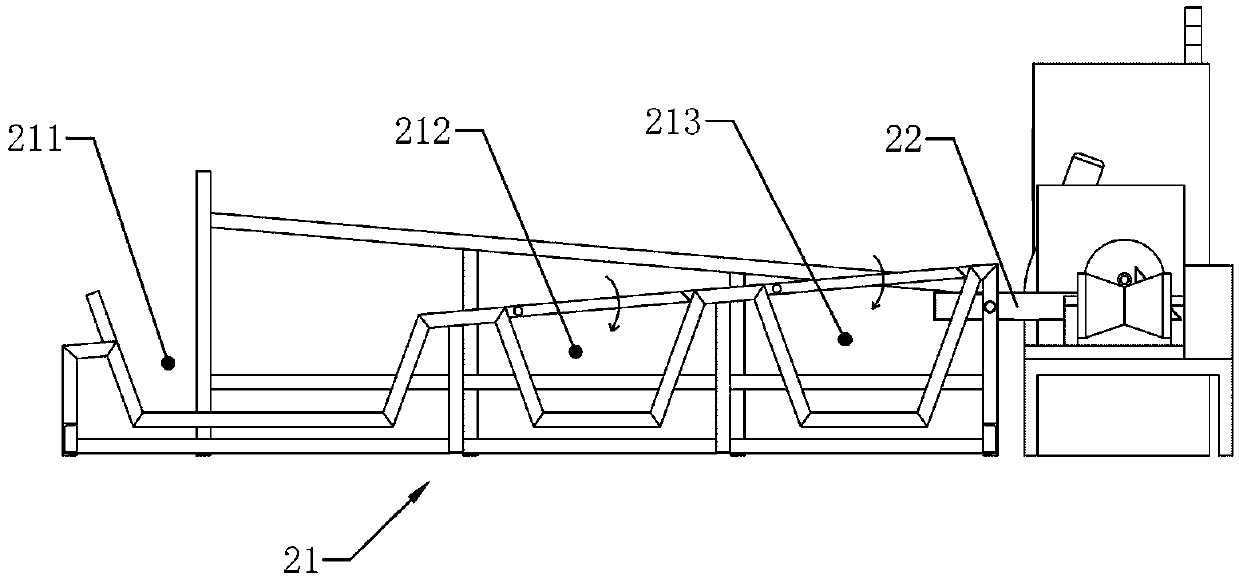

[0023] according to Figure 1 ~ Figure 3 As shown, an online detection and sorting device for steel pipes includes: a loading mechanism 1 for stacking and loading steel pipes to be inspected, a sorting mechanism 2 for stacking and sorting steel pipes that have been inspected, and a steel pipe from the upper The feeding mechanism 1 is transported to the conveying mechanism 3 of the sorting mechanism 2 and the display control mechanism 5 for controlling and displaying the working state of the whole device; the feeding mechanism 1 is a steel frame structure with an inclined top, and the conveying mechanism 3 is provided with The conveying rollers used to convey steel pipes in a row are steel frame structures with an inclined top and several storage areas; the feeding mechanism 1 and the sorting mechanism 2 are respectively located at the two ends of the conveying mechanism 3, and the conveying mechanism 3 is located on the feeding mechanism 1 and the sorting mechanism 2 are provi...

Embodiment 2

[0028] The difference from the above-mentioned embodiment 1 is that, along the direction of steel pipe transportation, a second marking part is installed downstream of the flaw detection part 43, and the second marking part adopts a two-color paint spraying device. When the flaw detection fails, the second marking part can use different colors respectively. The paint distinguishes and marks the defect sections on the inner and outer surfaces to facilitate the identification of defect types of steel pipes and facilitate repairs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com