Multifunctional television rear shell mould

A TV and multi-functional technology, applied in the field of multi-functional TV rear shell molds, can solve the problems of lower raw material temperature, no heat dissipation holes, and many operating processes, so as to reduce operating tools, reduce operating processes, and save operating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

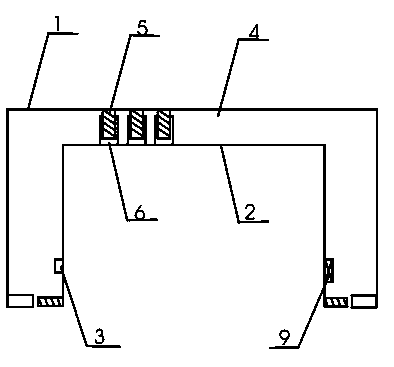

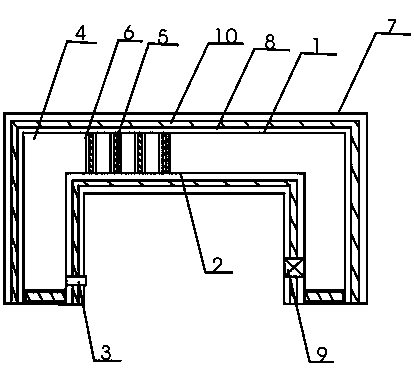

[0011] The present invention is a multi-functional television rear case mold, which includes an upper mold 1, a lower mold 2, a glue injection hole 3, and a molding cavity 4, and is characterized in that it also includes a heat dissipation protrusion 5, a heat dissipation concave hole 6, an insulation layer 7, Heating layer 8, exhaust hole 9, flowing water cooling layer 10, the upper mold 1 and the lower mold 2 are fastened together by a fixed structure to form a molding cavity 4, and the upper mold 1 is provided with a heat dissipation protrusion 5, and the heat dissipation protrusion 5 and the lower mold The heat dissipation concave holes 6 on the mold 2 are matched, and the upper mold 1 is sequentially provided with a heating layer 8, a flowing water cooling layer 10, and an insulating layer 7, and the lower mold 2 is also sequentially provided with a heating layer 8, a flowing water cooling layer 10, and an insulating layer. 7. One side of the lower mold 2 is provided with ...

Embodiment 2

[0013] When in use, first fasten the upper mold 1 and the lower mold 2 together, the heat dissipation protrusion 5 and the heat dissipation concave hole 6 are fixed together to achieve a good fixing effect, the raw material is injected into the molding cavity 4 through the injection hole 3, and the heating is turned on The heater in layer 8 heats the raw materials, and the insulation layer 7 keeps the raw materials warm. During injection molding, the gas in the molding cavity 4 is discharged out of the cavity through the exhaust hole 9, ensuring the quality of the product. When the injection molding is completed, stop the injection molding Then, cold water is injected into the flowing water cooling layer 10 through the water injection hole, and the cold water flows through the flowing water cooling layer 10 and then is discharged to the outside through the drainage hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com