Coating machine

A coating machine and frame technology, applied in the field of coating machines, can solve the problems of high processing accuracy accessories assembly requirements of the mobile table, out-of-sync on both sides, affecting product qualification rate, etc., to ensure coating quality and improve qualification rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

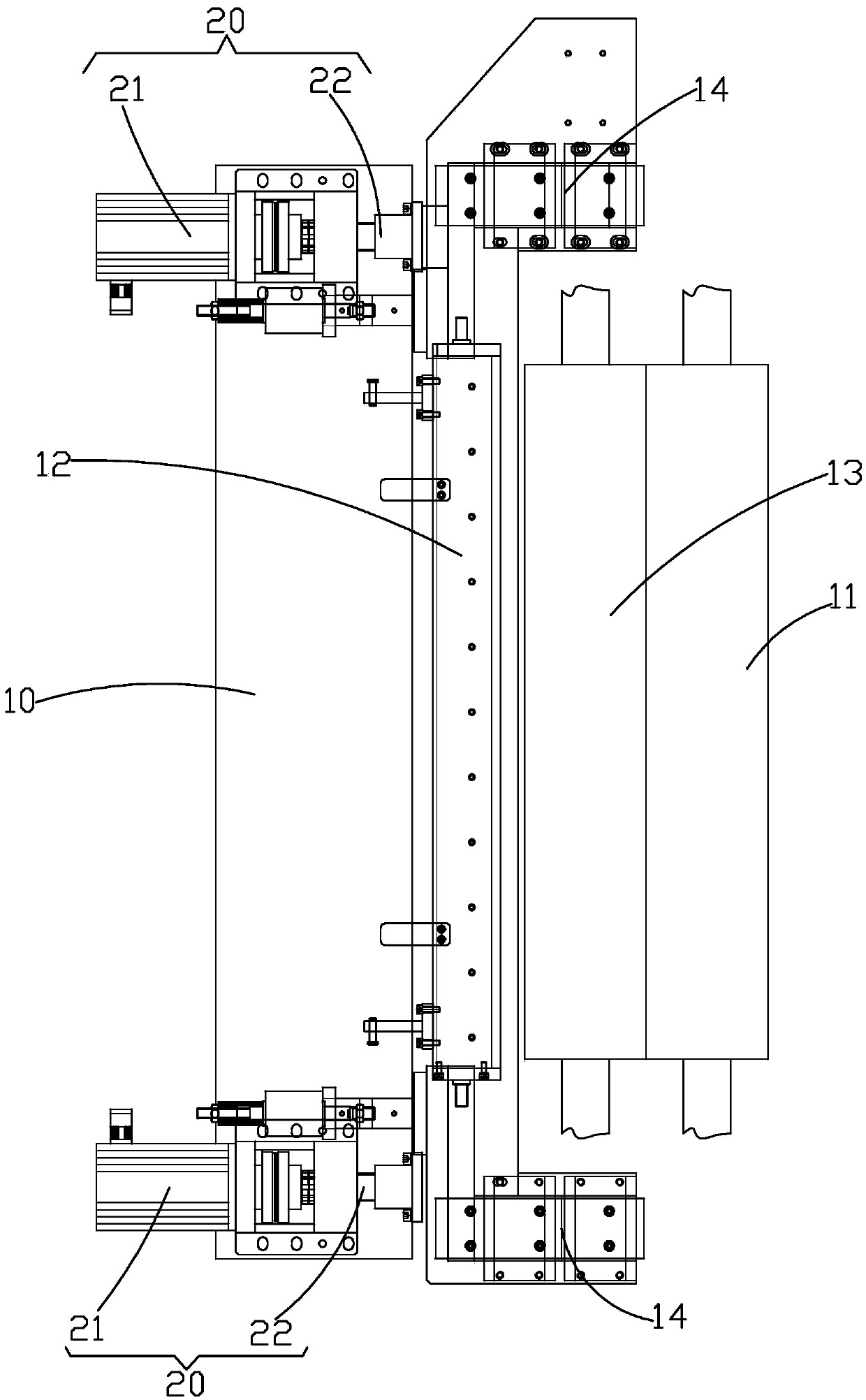

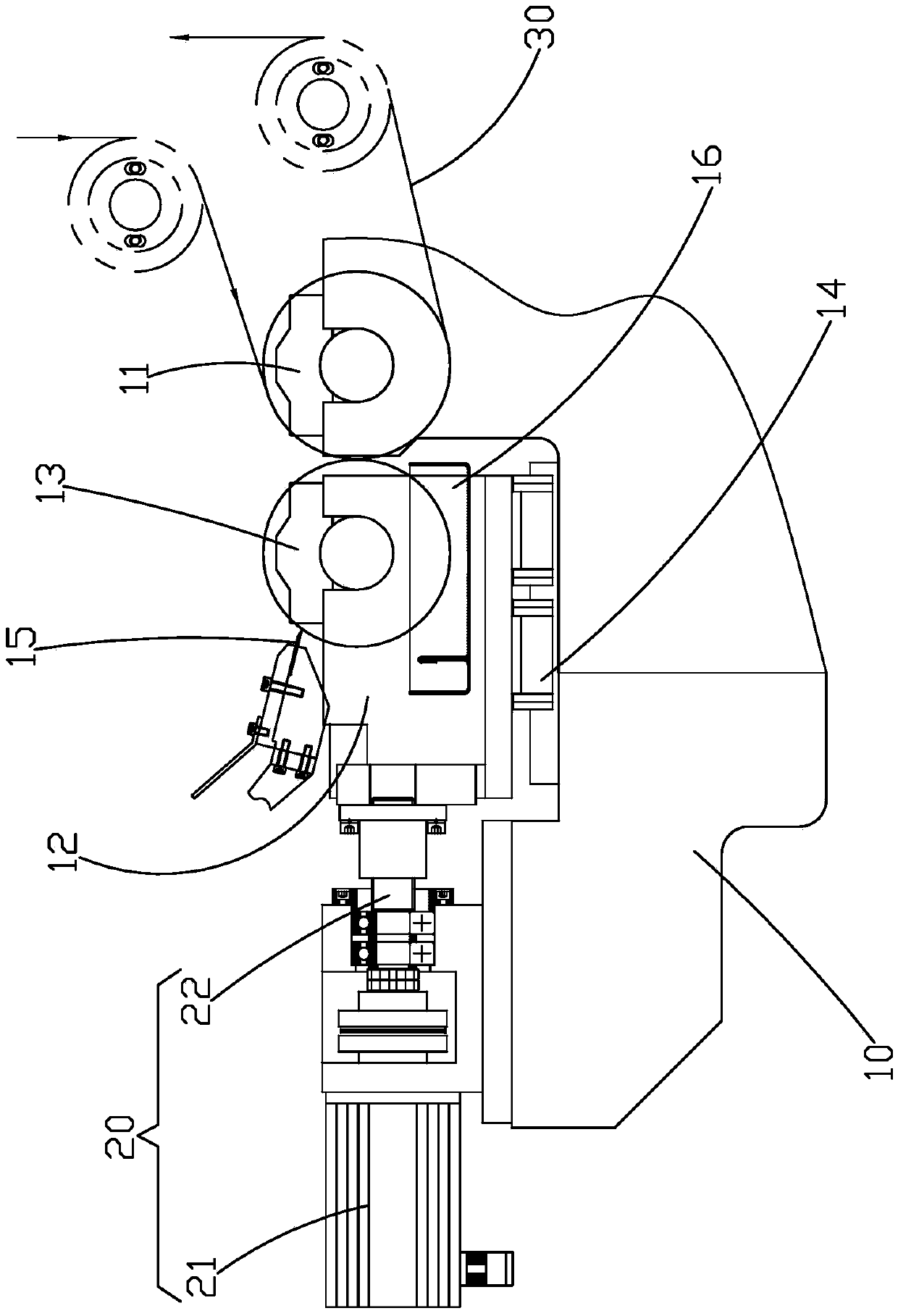

[0017] refer to figure 1 , figure 2 , a kind of coating machine, comprises a frame 10, and described frame 10 is provided with an embossing roller 11, and one side of described embossing roller 11 is provided with the movable platform 12 that is movably installed on described frame 10 , the mobile table 12 is provided with a gravure roller 13 that can follow the mobile table 12 to move close to or away from the embossing roller 11, and the frame 10 is provided with two groups for driving the mobile table 12 to move close to Or away from the driving mechanism 20 of the embossing roller 11 , two sets of driving mechanisms 20 are respectively connected to the two sides of the moving table 12 .

[0018] Because the present invention arranges two groups of driving mechanisms 20 to be connected with the both sides of mobile platform 12 respectively, drive mobile platform 12 reciprocating motion synchronously through two groups of driving mechanisms 20, can effectively solve the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com