Holographic image and grating image vision self-adapting synchronous print technique

A technology of holographic images and grating images, applied in printing devices, printing, typewriters, etc., can solve the problems of difficulty in guaranteeing absolute cutting accuracy, asynchronous image groups, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

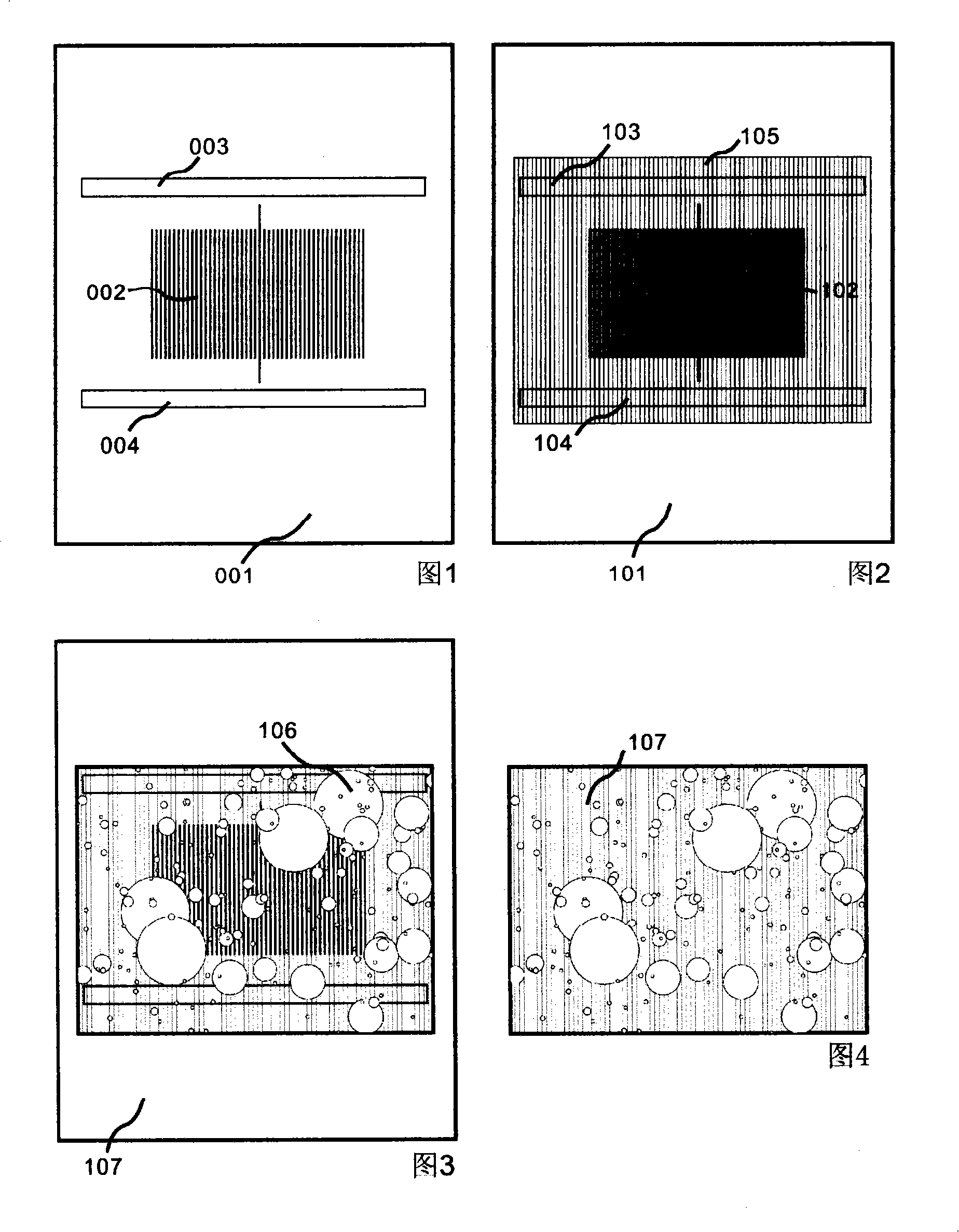

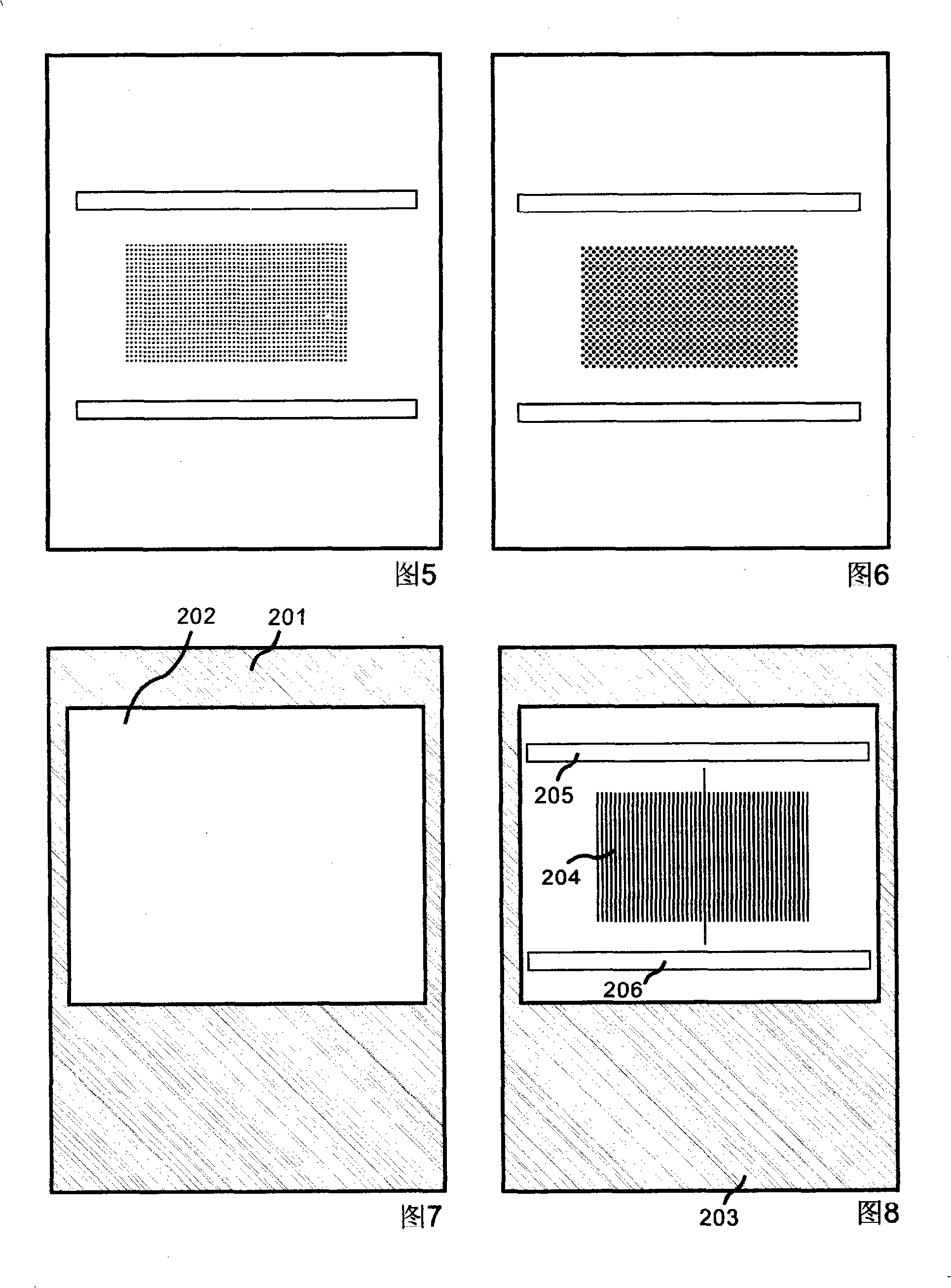

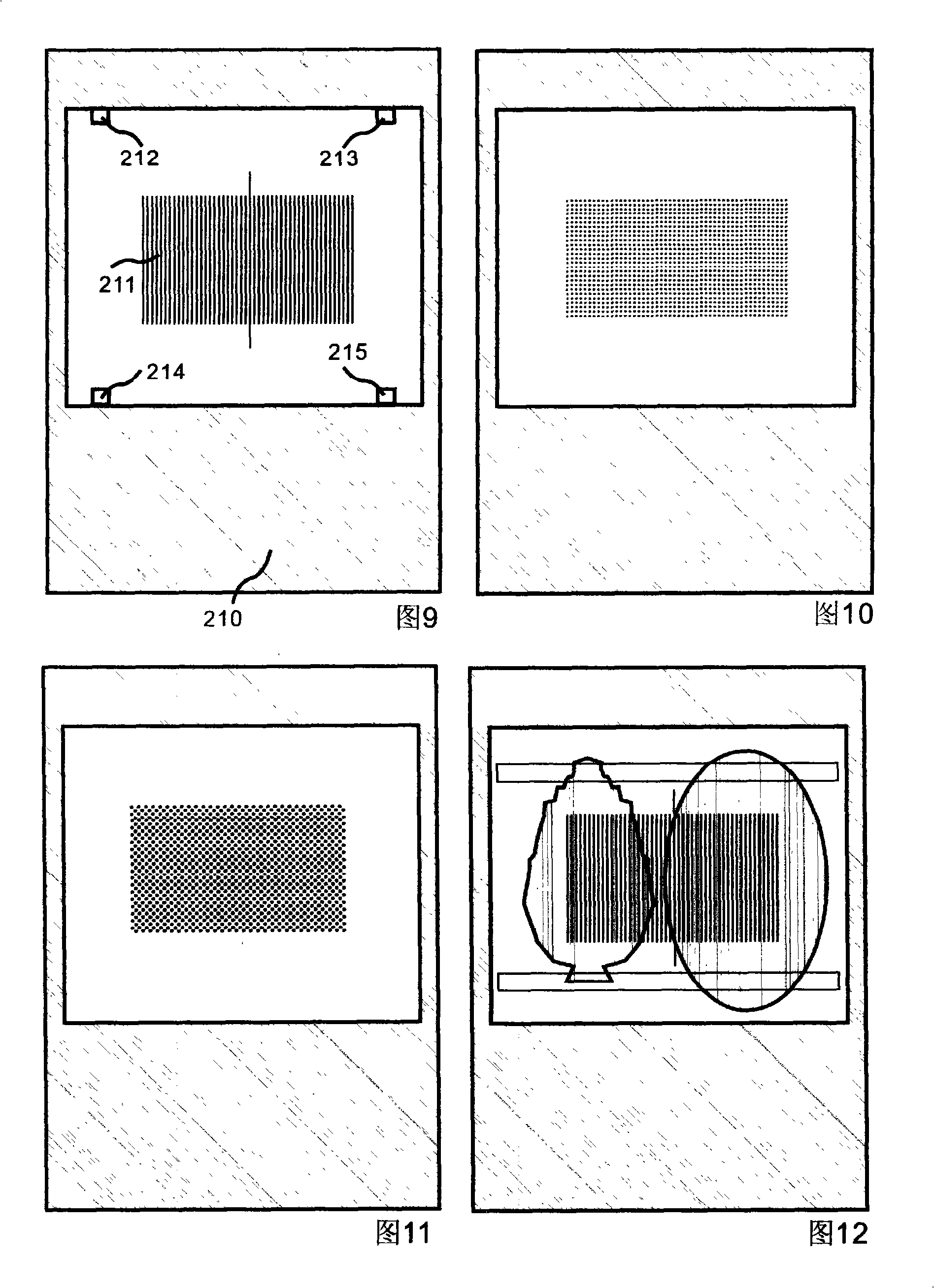

[0012] The visual adaptive synchronous printing technology of holographic image and raster image includes a computer synchronous parameter visual adaptive image generation system. When printing a holographic image, it can automatically produce a visual adaptive dot matrix image that is completely synchronized with the parameters of the holographic image material and has an adjustable duty cycle that is synchronized with the arrangement and spacing of the lens material according to the holographic image material parameters. The image includes matrix micro-lens material lattice image structure referring to FIG. 5, FIG. The visually adaptive image can be fixed when a completely black image appears on the normal viewing position during the visually adaptive synchronization step, and the processed carrier can be reinserted into the same printer, and then a holographic digital composite image is generated by the computer and provided to This printer carries out the step of image pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com