A leather dropping mechanism

A cloth and leather technology, which is applied in the field of leather falling mechanism, can solve the problems of stretching and shrinkage of the base fabric, affecting the quality of the base fabric, and uncontrollable tension of the conveying equipment, etc., to achieve the effect of expanding the scope and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

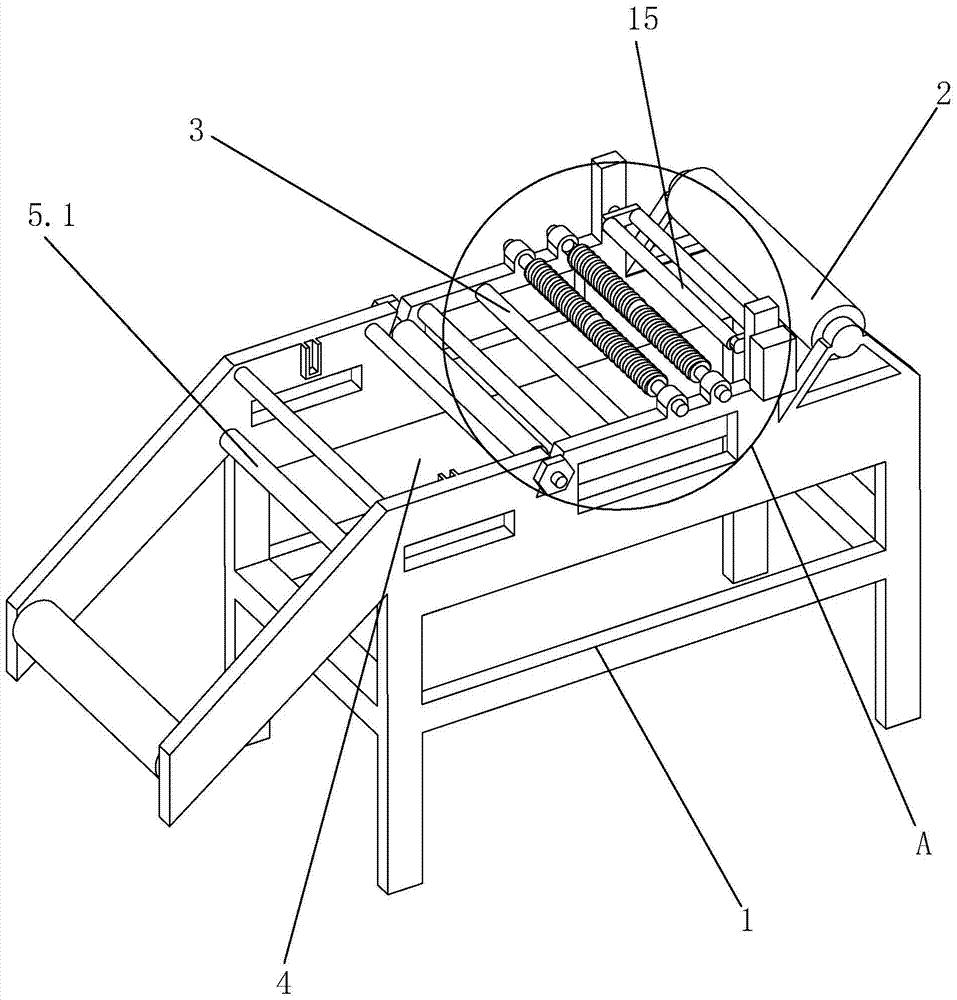

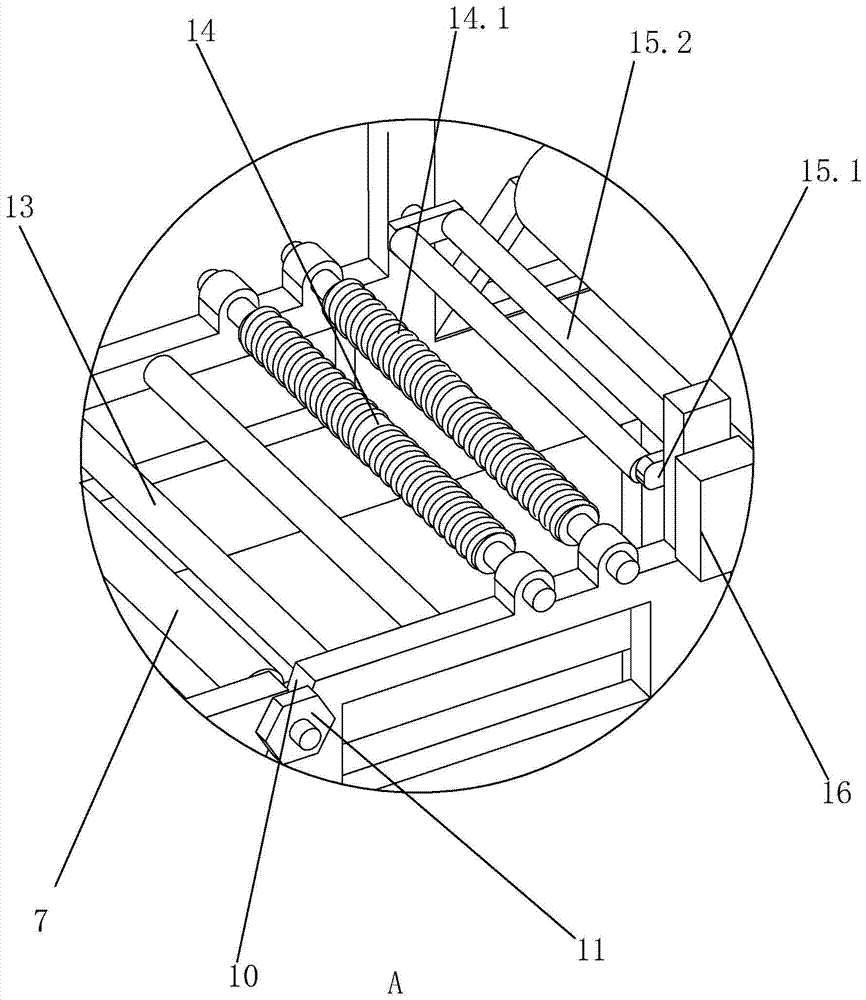

[0042] Embodiment one, with reference to Figure 1 to Figure 2 , a leather cloth drop mechanism, the cloth outlet end 2 is consistent with the prior art, including a cloth outlet frame, the base cloth is wound on the cloth outlet frame, and a plurality of guide cloths for positioning the base cloth are also arranged on the frame 1 Roller 3, when the base fabric starts from the cloth outlet end 2, and then enters the spreading rod group 15, the spreading rod group 15 includes two spreading rods 15.2, since the base cloth is always attached to the spreading rod group 15, so that When the spreader rod group 15 rotates, the two spreader rods 15.2 tap the surface of the base cloth one by one to spread out the base cloth. On the side, one of the connecting rods 15.1 is linked with the motor 16. When the motor 16 rotates, the connecting rod 15.1 drives the two spreading rods 15.2 to rotate.

[0043] refer to figure 2 , the base cloth then enters on the spreader roller 14, the spre...

Embodiment 2

[0047] Embodiment two, refer to Figure 6 , Figure 7 , a leather drop cloth mechanism, compared with the first embodiment, the difference is that when adjusting, the position of the adjusting rod 7 can be adjusted by adjusting the position of the adjusting member 9 on the threaded plate 8, and the adjusting member 9 can use bolts , the bolt passes through one end of the adjusting rod 7 and is threadedly connected with the threaded plate 8, and then realizes the change of the position of the adjusting rod 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com