A reliable connection and adjustable bearing preload structure and assembling method

A method of assembling and adjusting, a bearing technology, applied in the direction of bearing assembly, shaft and bearing, bearing components, etc., can solve problems such as complicated operation, and achieve the effect of simple operation and uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0031] The invention provides a reliably connected and adjustable bearing pre-tightening structure and an assembling method.

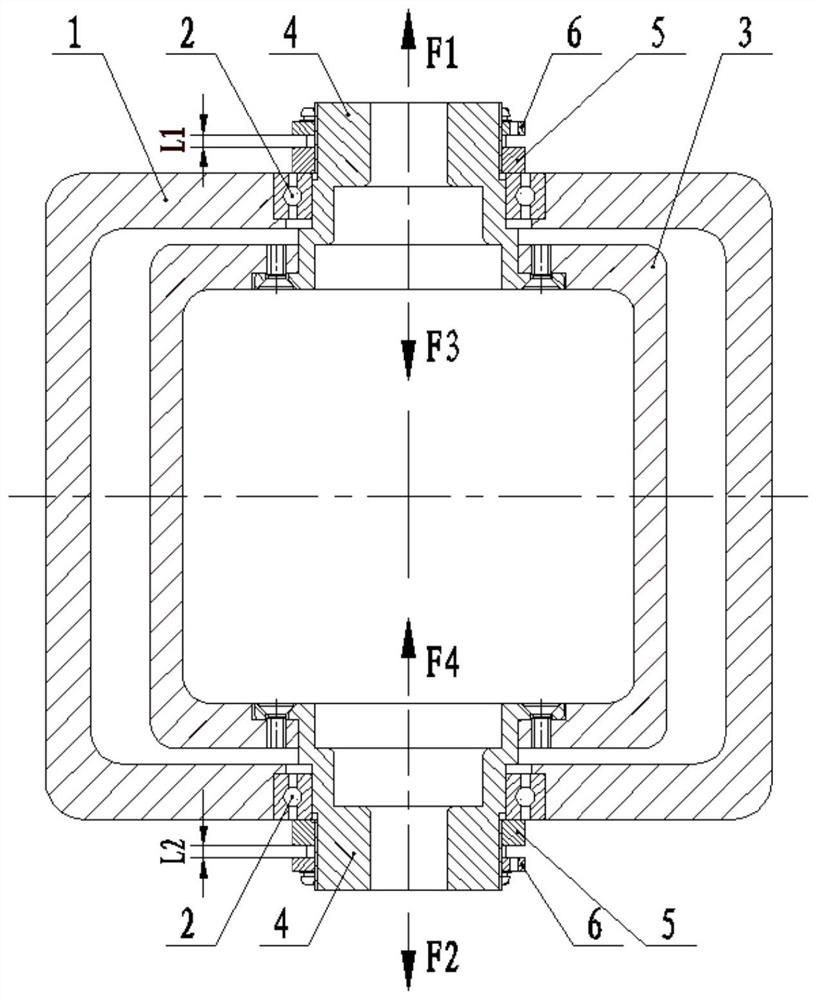

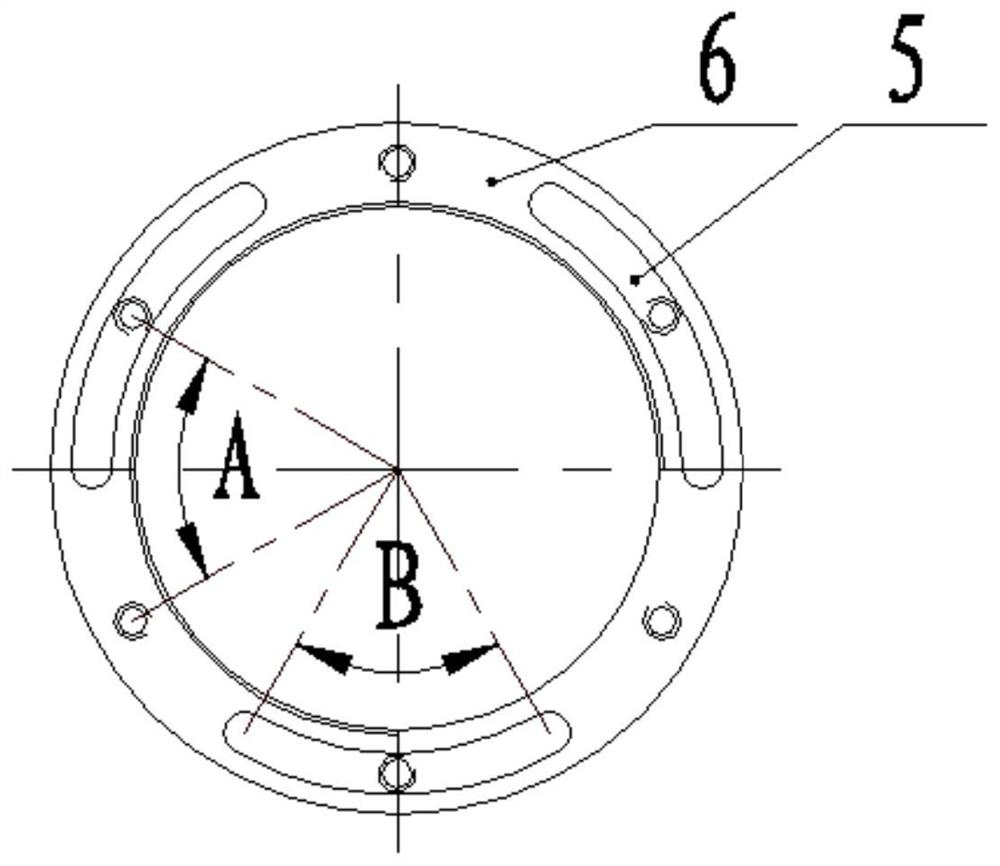

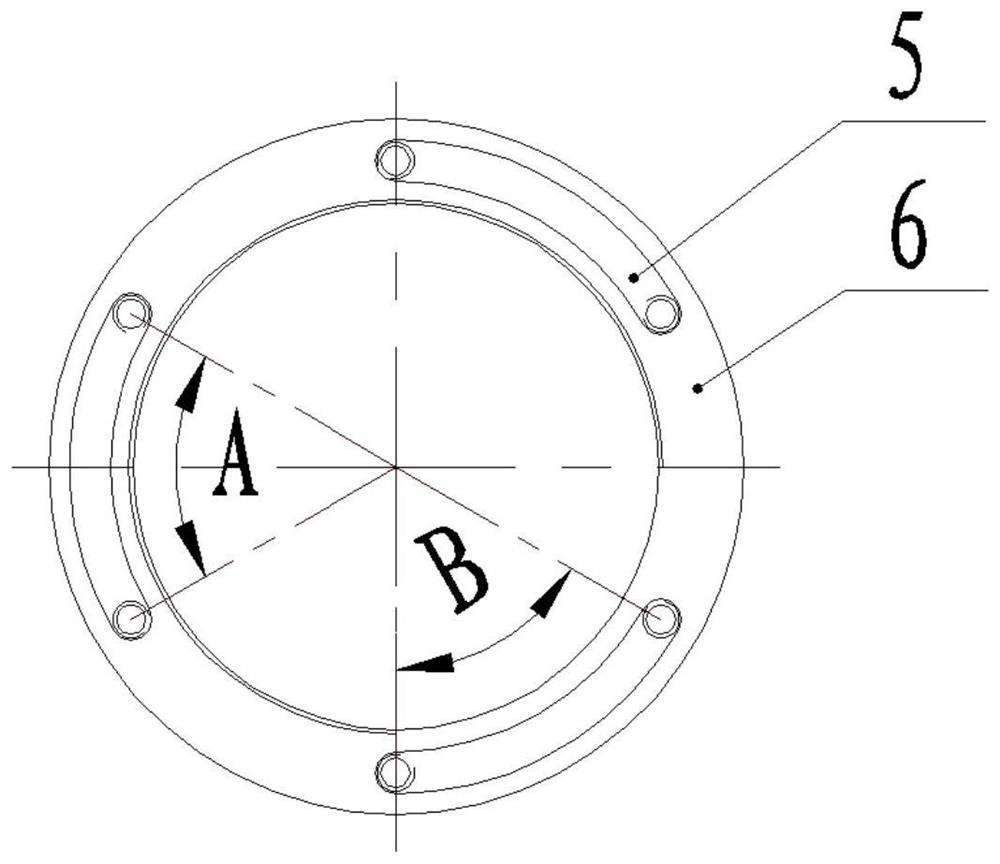

[0032] like figure 1 As shown, the reliable connection and adjustable bearing preload structure of the present invention includes: outer frame 1, bearing 2, inner frame 3, rotating shaft 4, adjustment ring 1 5, adjustment ring 2 6 and fasteners, etc. The frame 1 and the inner frame 3 are both closed frame structures. The two bearings 2 are respectively installed in the torus of the stepped structure on both sides of the outer frame 1. The two torus surfaces of the outer frame 1 have the same size and are coaxial. The two bearings 2 The outer circular surface is in interference fit with the two annular surfaces of the outer frame 1, the inner frame 3 is inside the outer frame 1, the two annular surfaces of the inner frame 3 have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com