Tempering and forming device of hole-digging and bending glass plate

A glass plate and bending technology, which is applied in the field of tempering forming devices and tempering forming devices for curved glass plates, can solve the problems of easy deformation of the digging part, easy displacement of the yield, and easy breakage, so as to improve the quality of the profile and the finished product rate, avoid shading or waves, and solve the effect of easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described below in conjunction with the accompanying drawings.

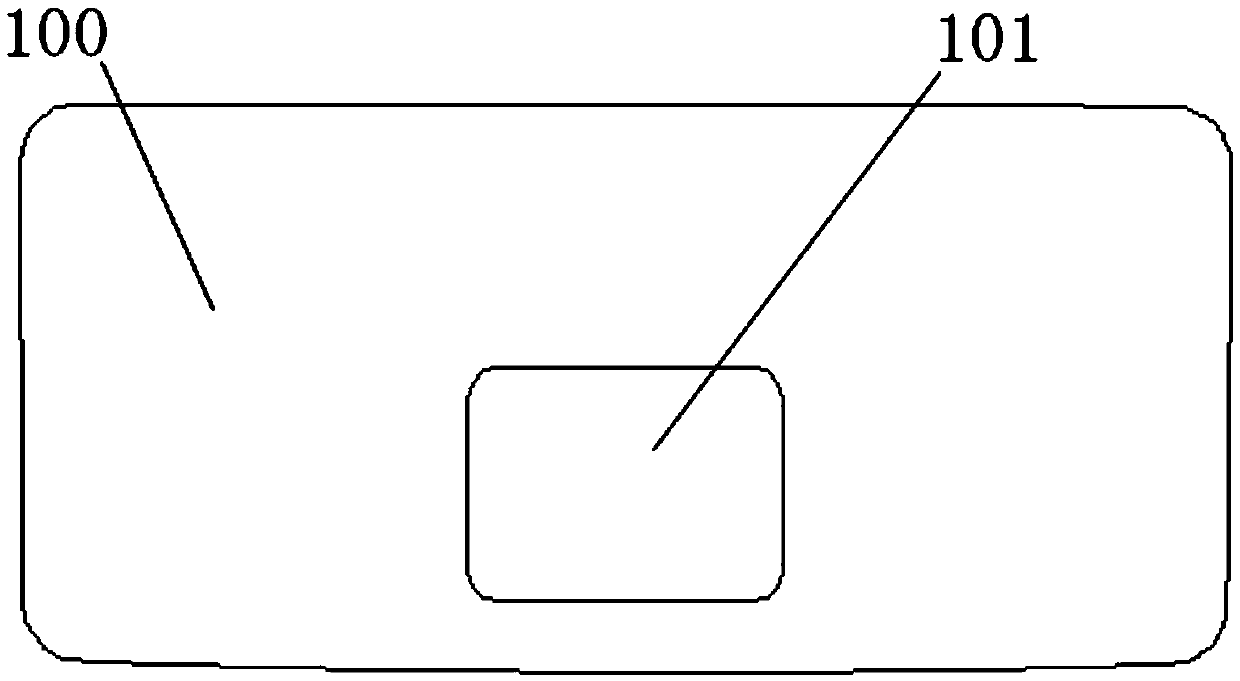

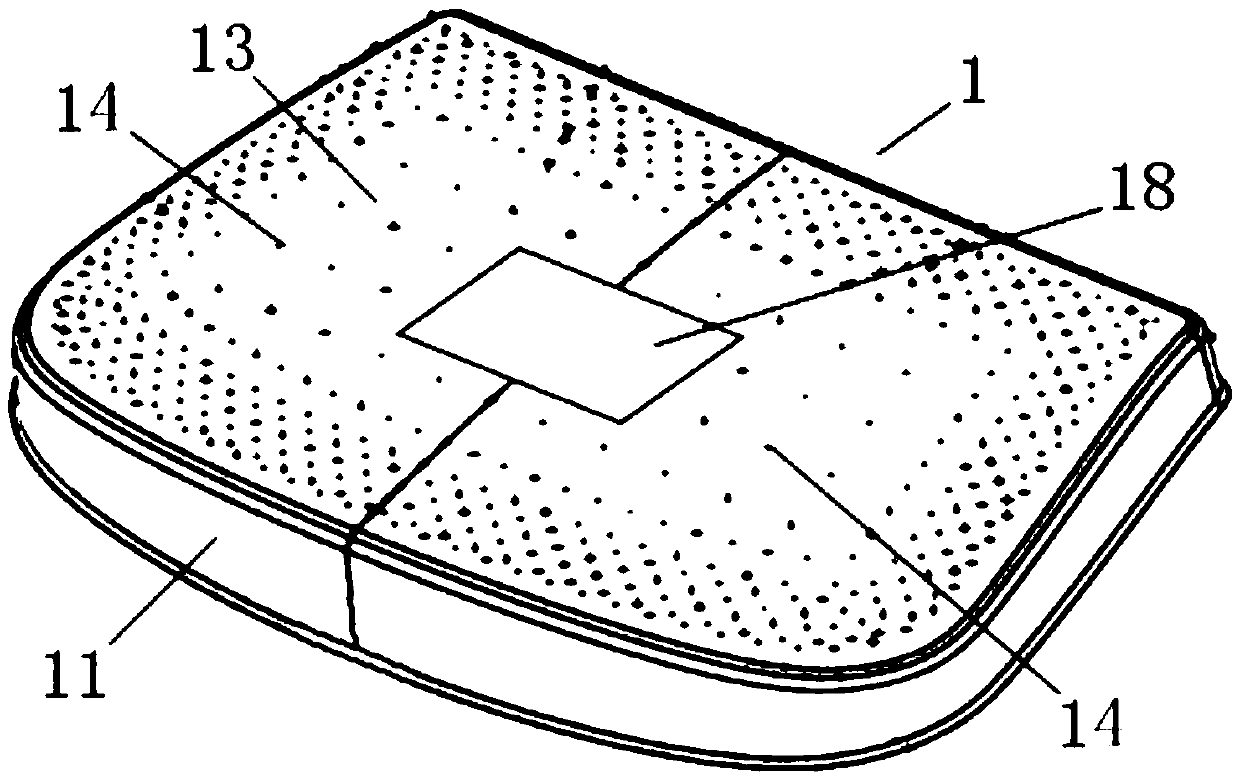

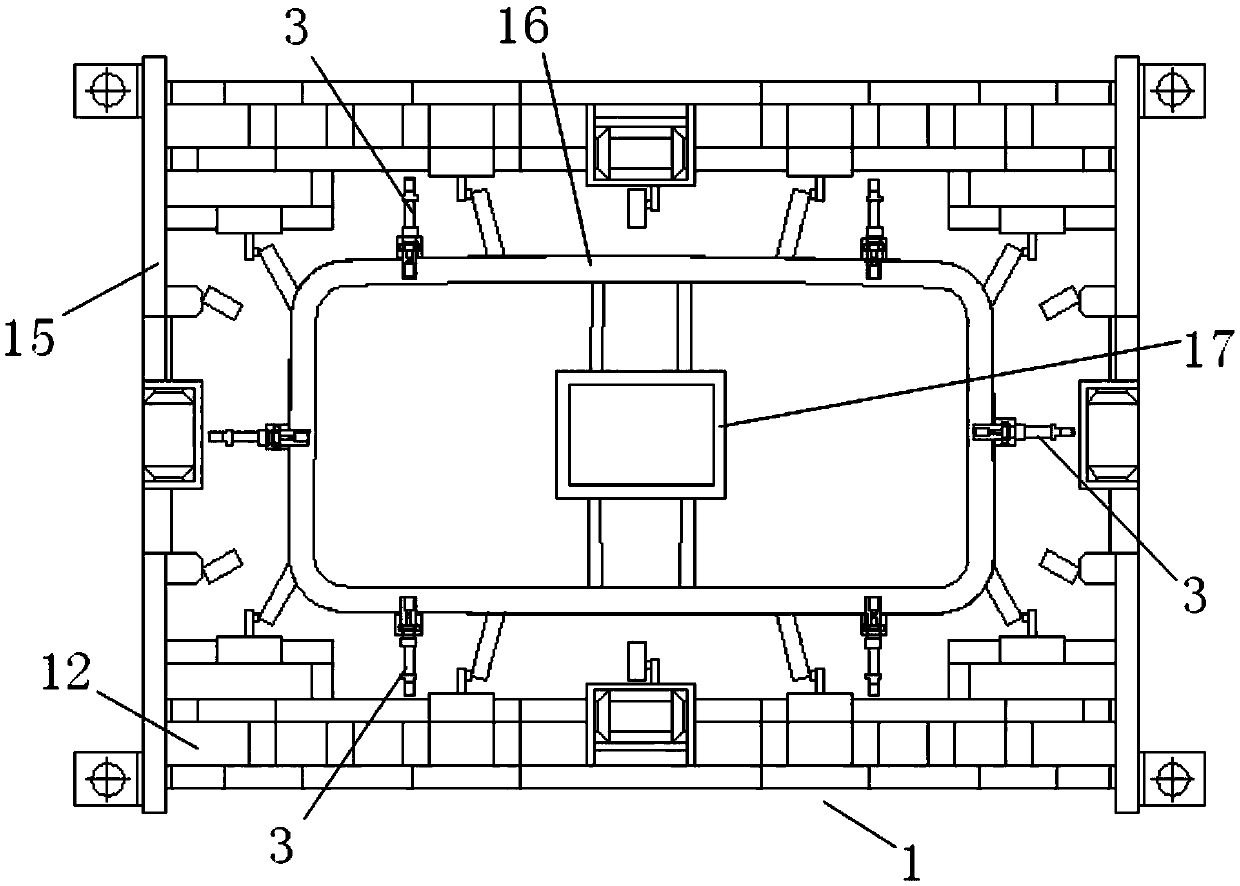

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a tempering and forming device for digging and bending a glass plate according to the present invention is used for tempering and forming a digging and bending glass plate 100 with a through hole 101, which includes a bending mold 1 and a cooling grid 2, A common glass substrate usually with a through hole 101 is moved by being transported on a conveying mechanism (not shown) in a heating furnace (not shown) and heated to a softening temperature, and then entered into a bending mold 1 to be pressed and bent, and then After entering the cooling air grid 2, it is cooled and tempered by blowing air, and finally a bent glass plate 100 with holes is obtained.

[0021] exist figure 2 Among them, the bending mold 1 includes an upper pressing punch 11 and a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com