System for adding grease for efficient silk threads

A high-efficiency silk thread technology, applied in the direction of textiles and papermaking, can solve the problems affecting sales and export, the oil content of silk thread is difficult to meet the standard, and the oiling efficiency is low, so as to facilitate trade and export, facilitate follow-up processing or movement, and facilitate The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

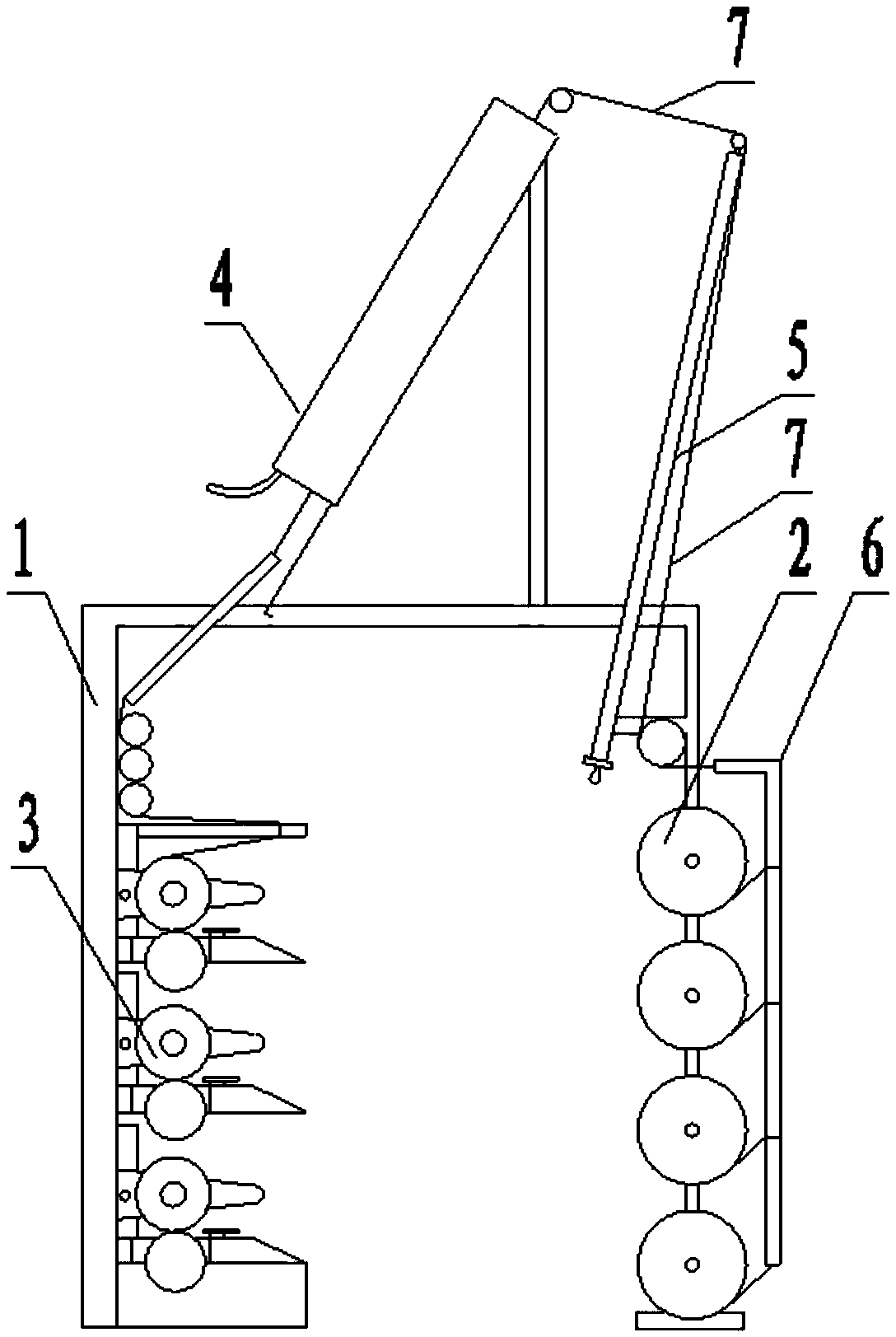

[0025] Example. A high-efficiency grease adding system for silk thread, which is composed of Figures 1 to 9 As shown, including frame 1, one side of frame 1 is provided with a plurality of vertically distributed precursor tubes 2, and the other side of frame 1 is provided with a plurality of winding devices 3; above winding device 3 and A heat treatment device 4 and a wire raising device 5 are arranged above the raw yarn drum 2 respectively, and the heat treatment device 4 and the wire raising device 5 are connected;

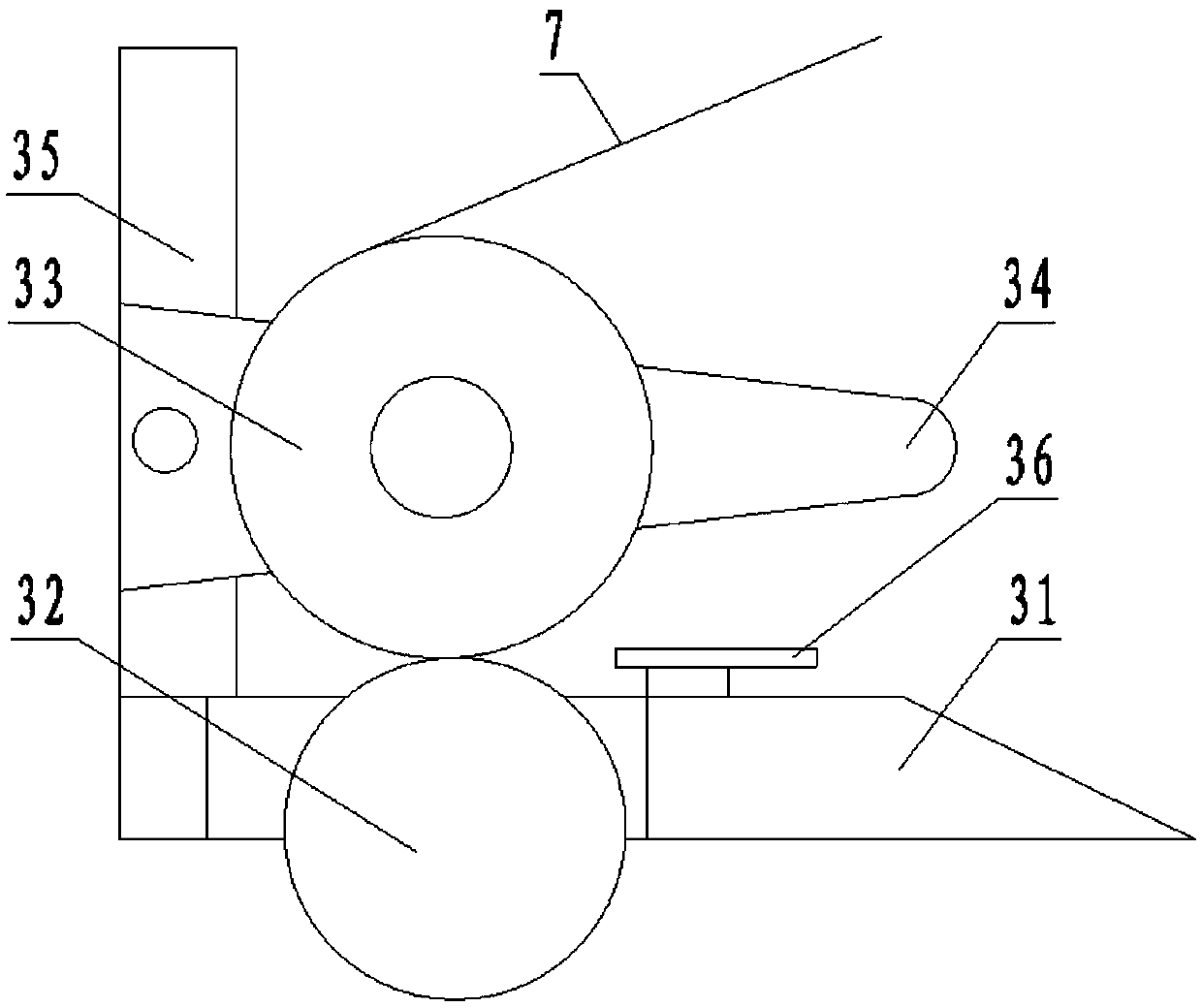

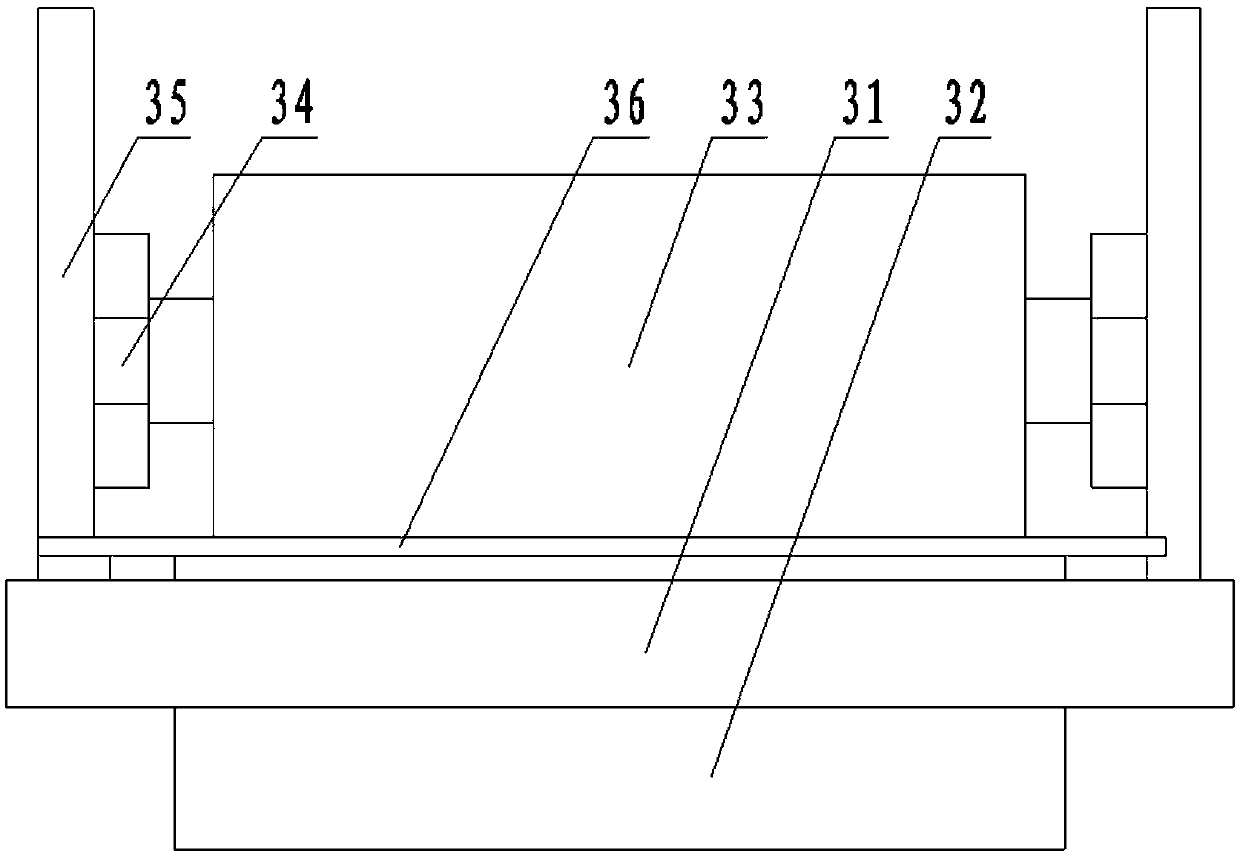

[0026] The winding device 3 includes a winding frame 31, the inside of the winding frame 31 is provided with a winding roller 32; the top of the winding roller 32 is provided with a winding drum 33, and both sides of the winding drum 33 are provided with a bobbin holder 34 , One end of the bobbin frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com