Precast beam hoisting positioner and precast beam hoisting construction method

A positioning device and prefabricated beam technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult one-time accurate positioning, time-consuming, complicated operation process, etc., so as to avoid the displacement adjustment process and save construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

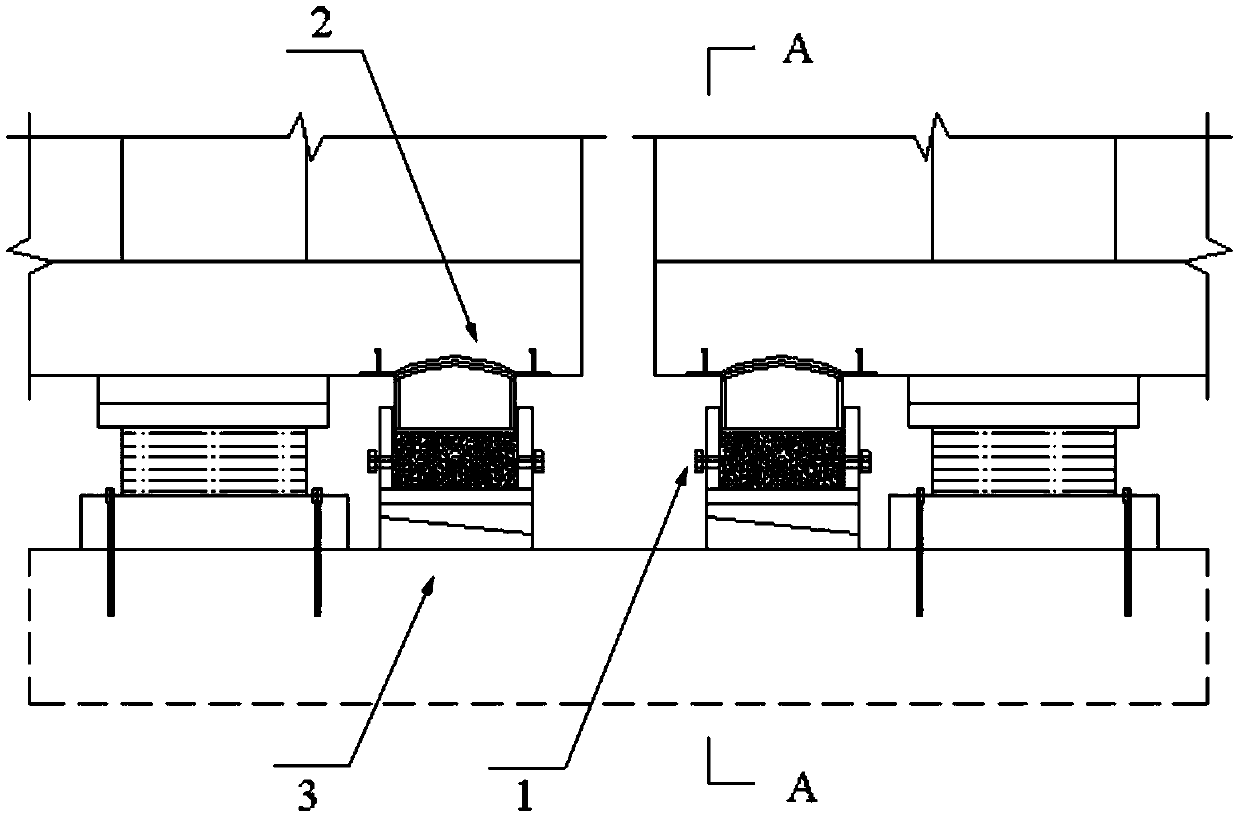

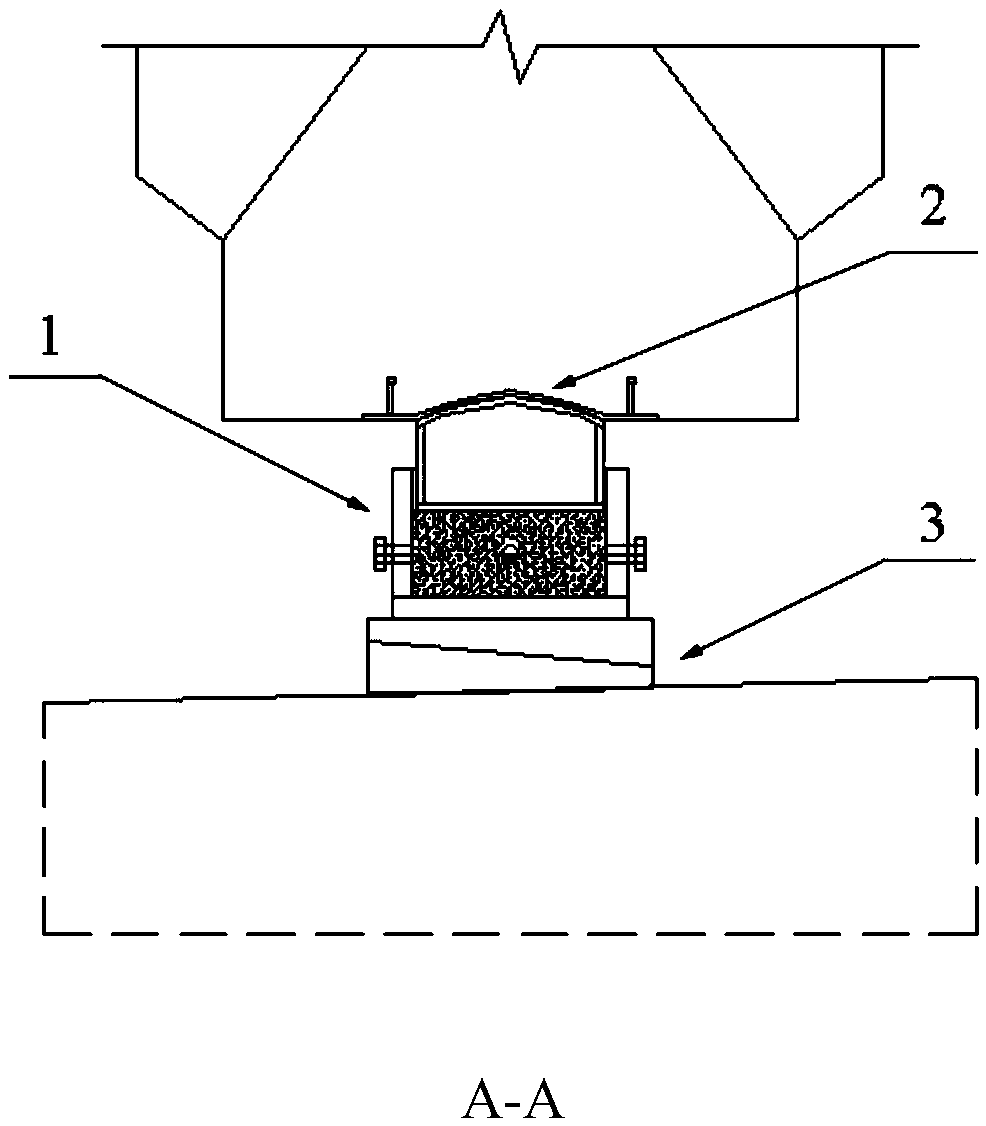

[0035] see figure 1 and figure 2 As shown, the present invention provides a prefabricated beam hoisting and positioning device, which includes a positioning sand box 1 , a pre-embedded device 2 and an adjusting device 3 . Wherein the pre-embedded device 2 is fixed at the bottom of the prefabricated beam, and the positioning sand box 1 is fixed beside the support at the top of the pier. The adjusting device 3 is located between the bottom of the positioning sand box 1 and the pier.

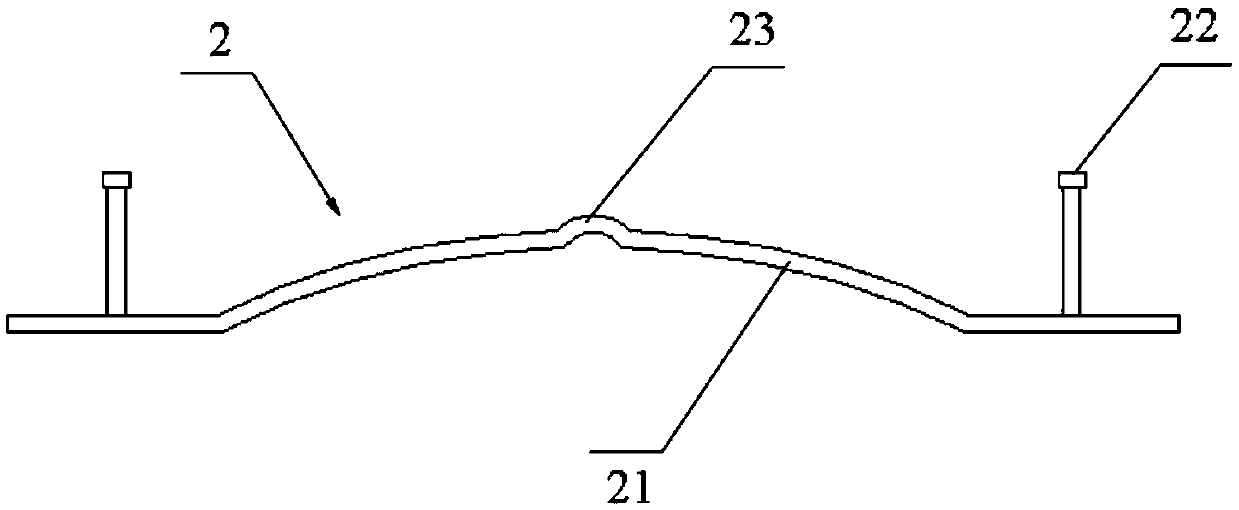

[0036] see also image 3 and Figure 4 As shown, the embedded device 2 is made of a complete stainless steel plate, which includes an arc guide part 21 and embedded bolts 22 . The pre-embedded bolts 22 are firmly welded to the arc-shaped guide part 21, and the top of the arc-shaped guide part 21 is also provided with a positioning groove 23 consistent with the concave direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com