A prefabricated folded steel plate shear wall with two-sided connections and a plastic hinge guiding mechanism

A steel plate shear wall and plastic hinge technology, applied to walls, building components, and earthquake resistance, can solve problems such as increasing construction difficulty, increasing energy consumption, and weakening the ultimate bearing capacity and lateral stiffness of steel plate shear walls. Achieve the effect of improving ultimate bearing capacity, improving energy dissipation performance and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

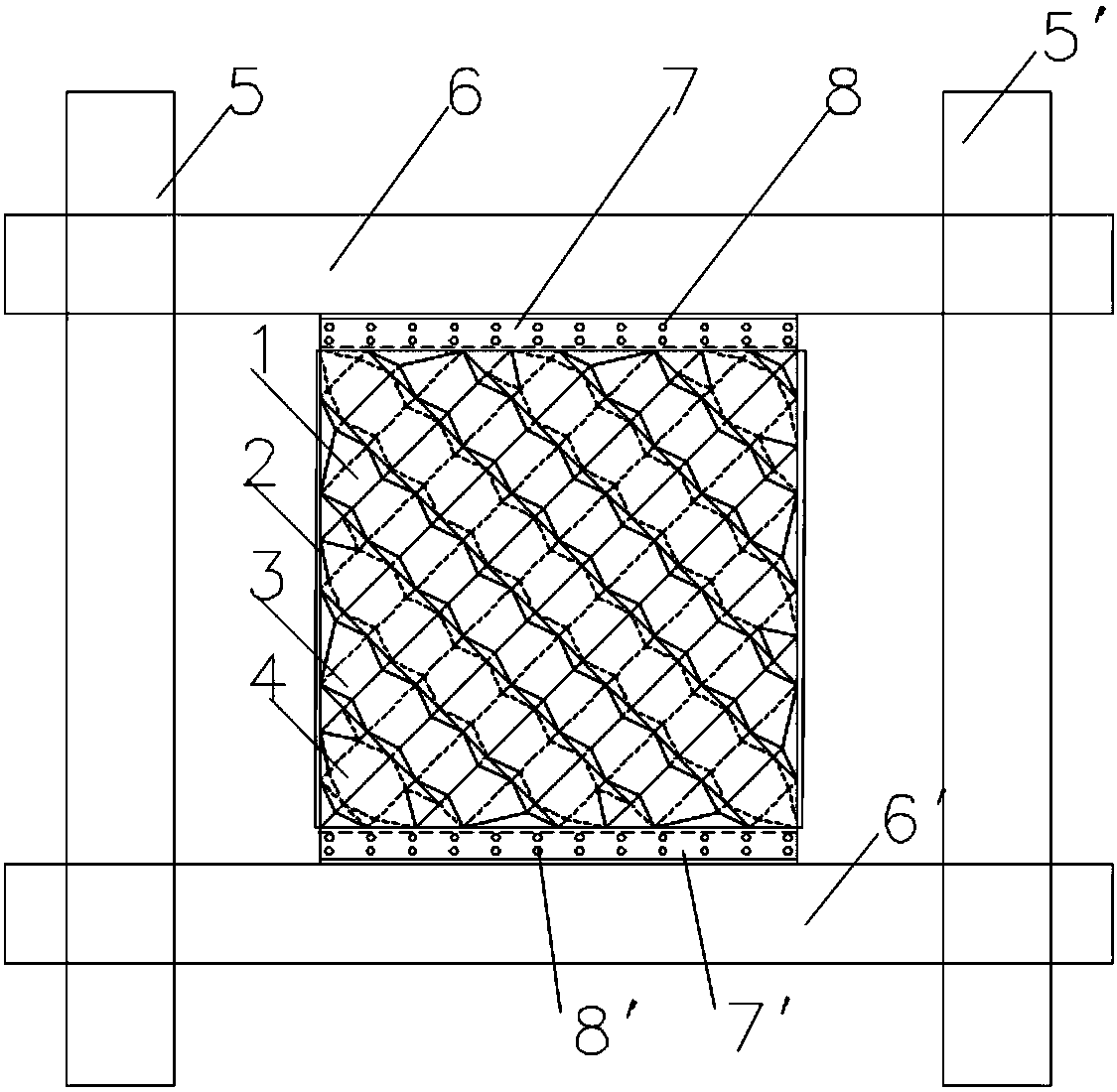

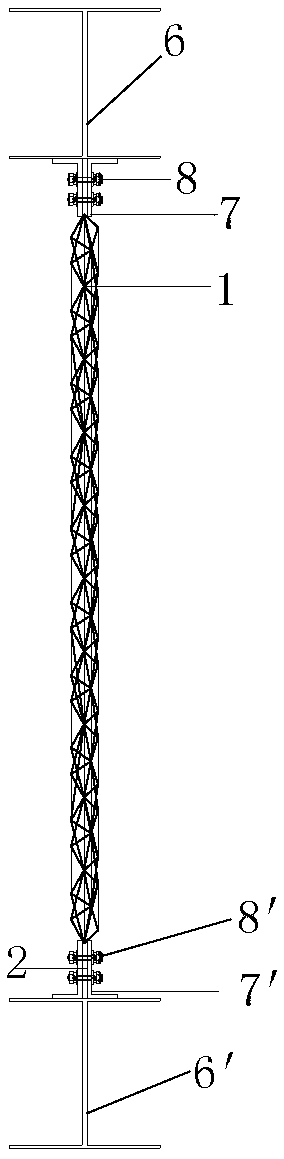

[0029] Combine below Figure 1-9 The shown two-side connected assembled folded steel plate shear wall with plastic hinge guiding mechanism will further describe the specific embodiment of the present invention:

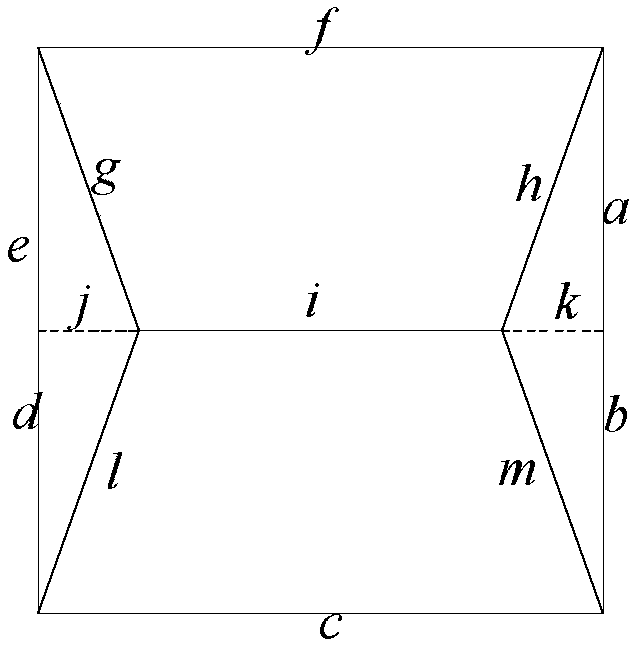

[0030] Such as figure 1 The shown two sides are connected with the prefabricated folded steel plate shear wall with a plastic hinge guiding mechanism, and the folded steel plate 1 is formed by special mechanical stamping according to the predetermined creases. Such as figure 1 As shown in , the solid line is the convex crease when viewed from the front, and the dotted line is the concave crease when viewed from the front. The relationship between the local coordinate system of the crease subunit and the overall coordinate system of the steel plate shear wall is as follows: Figure 9-10 shown. The appearance of the crease can be regarded as being composed of the first type of crease subunit 3 and the second type of crease subunit 4 connected according to certain to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com