Brick laying device and brick laying method

A brick laying device and brick laying technology, applied in the direction of construction and building structure, can solve the problems of affecting the quality of laying, construction environment pollution, construction difficulty, etc., to improve the reuse rate, reduce industrial pollution, and speed up construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with examples. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

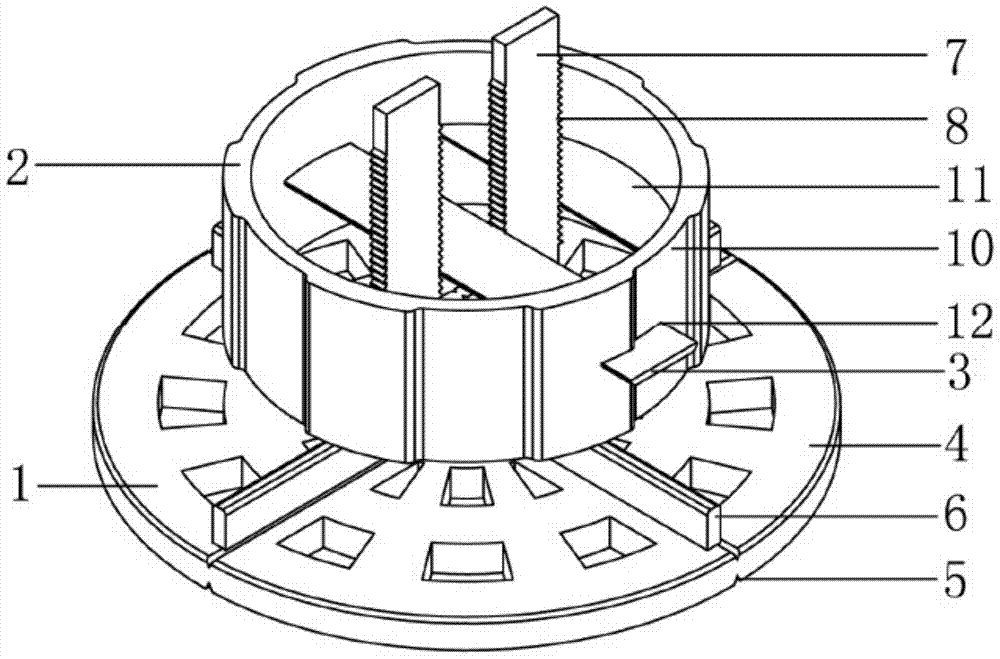

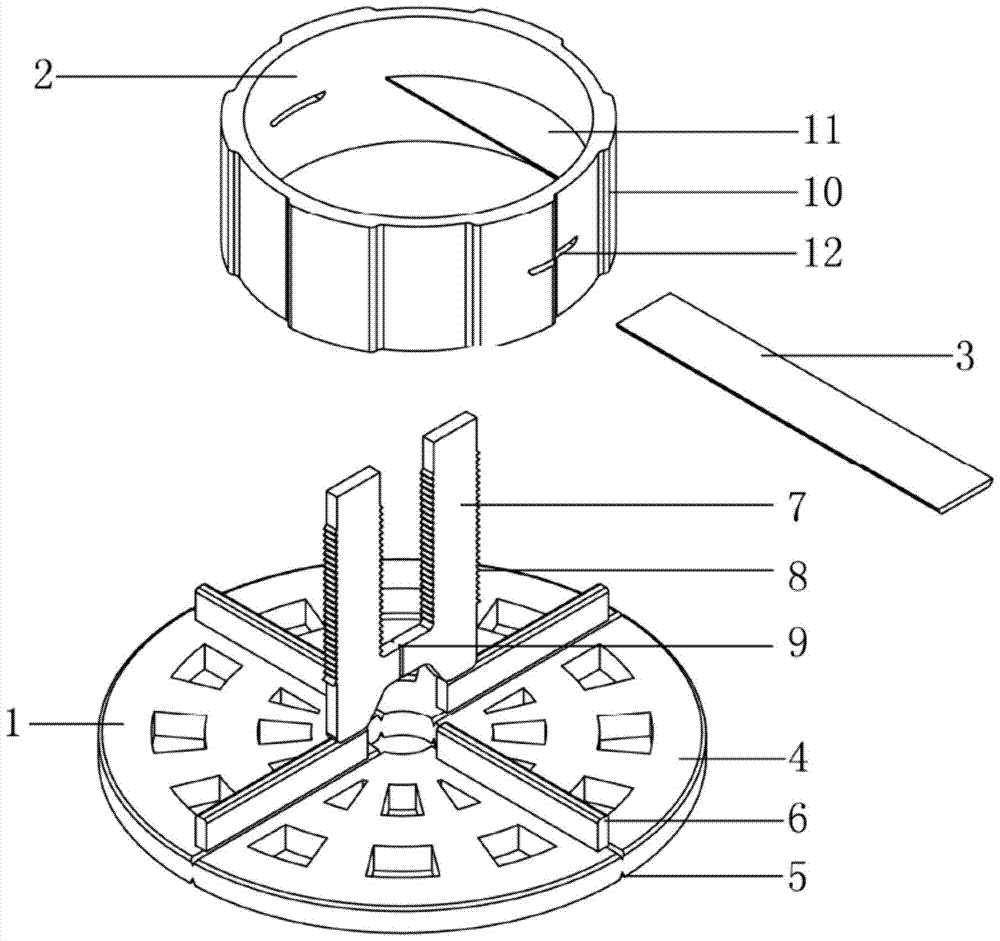

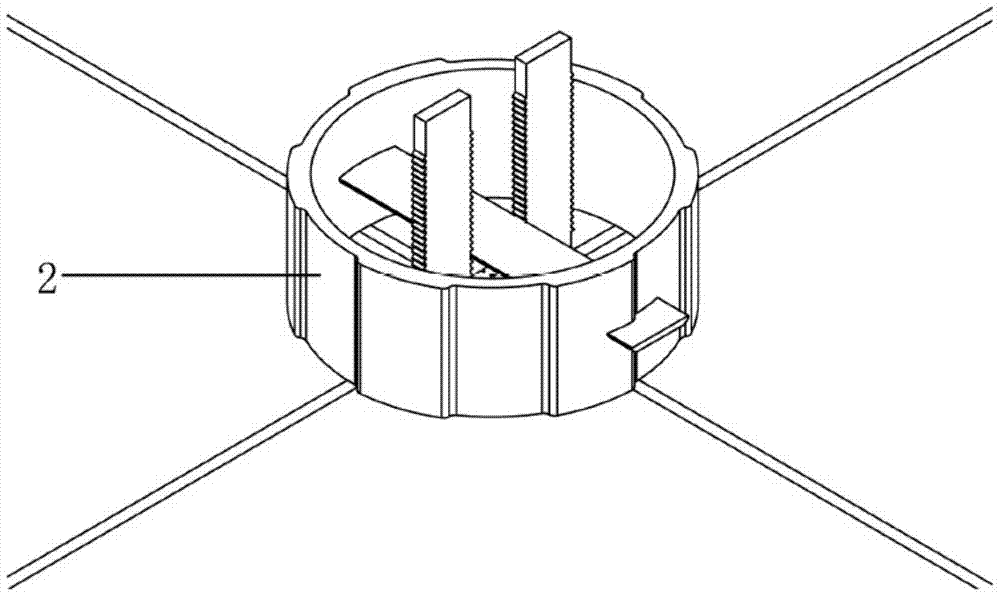

[0024] figure 1 It is a preferred embodiment of the brick laying device of the present invention; figure 2 yes figure 1 An exploded view of the tiling apparatus shown in . combine figure 1 with figure 2 As shown, the brick laying device provided in the preferred embodiment of the present invention includes a fixing part 1 and a leveling part 2 , and the fixing part 1 includes a base 4 and a fixing strip 7 . In general, the tile laying device provided by the present invention restricts the facing tiles to be laid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com