Method for predicting production effect of shale reservoir after size modification

A technology of production effect and volume transformation, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of not taking into account the stress-sensitive effect of heterogeneity in ultra-low permeability gas reservoirs at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0183] In this embodiment, a method for predicting the production effect after volume fracturing of shale reservoirs is applied, specifically as follows:

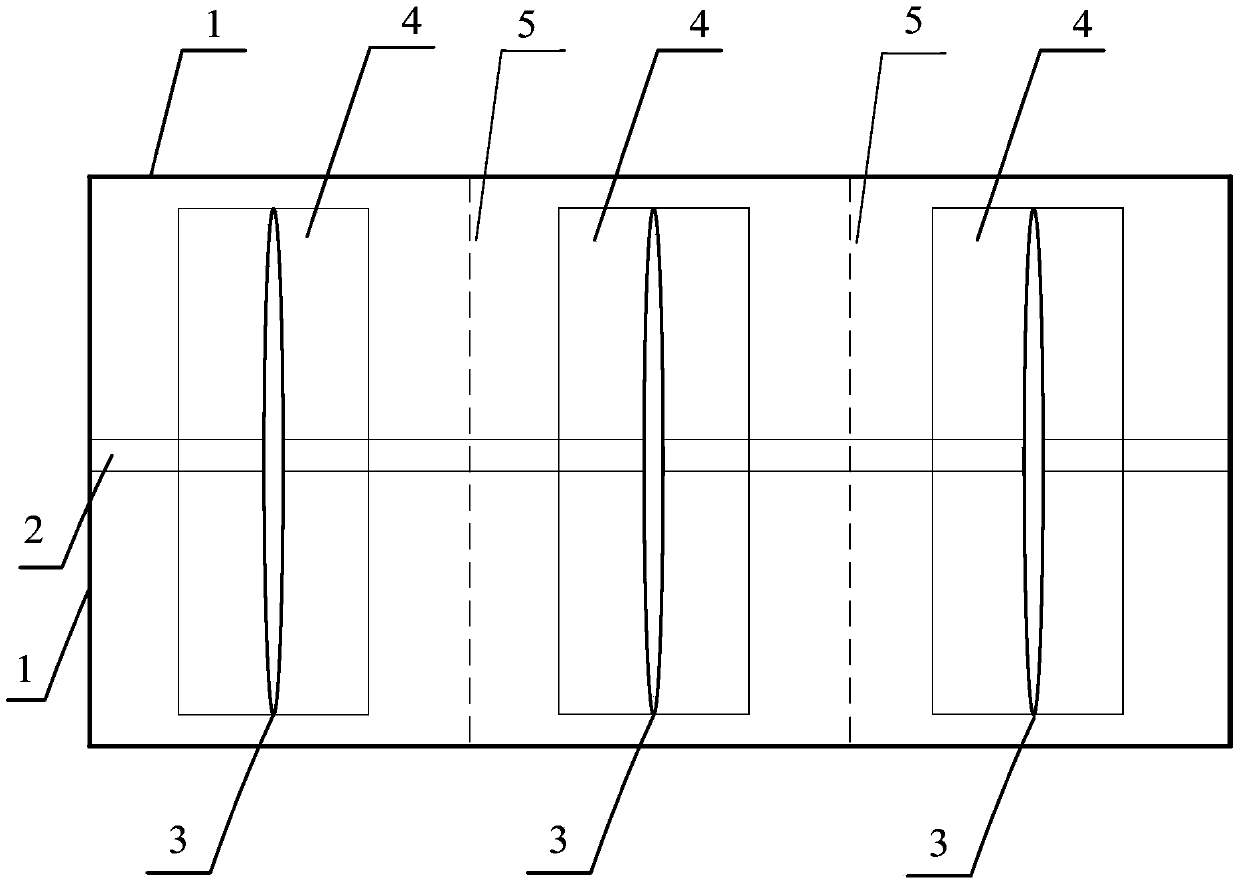

[0184] The basic parameters of a horizontal well in a heterogeneous shale gas reservoir are as follows: the length of the heterogeneous gas reservoir is 1000 m, the width is 120 m, the thickness is 20 m, the porosity is 3%, the closed boundary pressure is 30 MPa, and the internal pressure of the horizontal wellbore is 25 MPa. Three heterogeneous vadose zones, matrix permeability deformation factor is 0.015MPa -1 ;A total of 9 fractures were formed by segmented multi-cluster perforation with packer, see Table 1. The half-length of all fractured networks is 60m, and the reconstruction volume of a single fracture is = 20m (the width of the fractured network) × 120m (the length of the fractured network) × 20m (the height of the fractured network) = 48000m 3 , the permeability of the fracture network high permeability zone is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com