Installation oil groove for vane pumps

A vane pump and oil tank technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluid, can solve the problems of easy cleaning and damage, and achieve the effect of protecting health, avoiding damage and draining oil. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

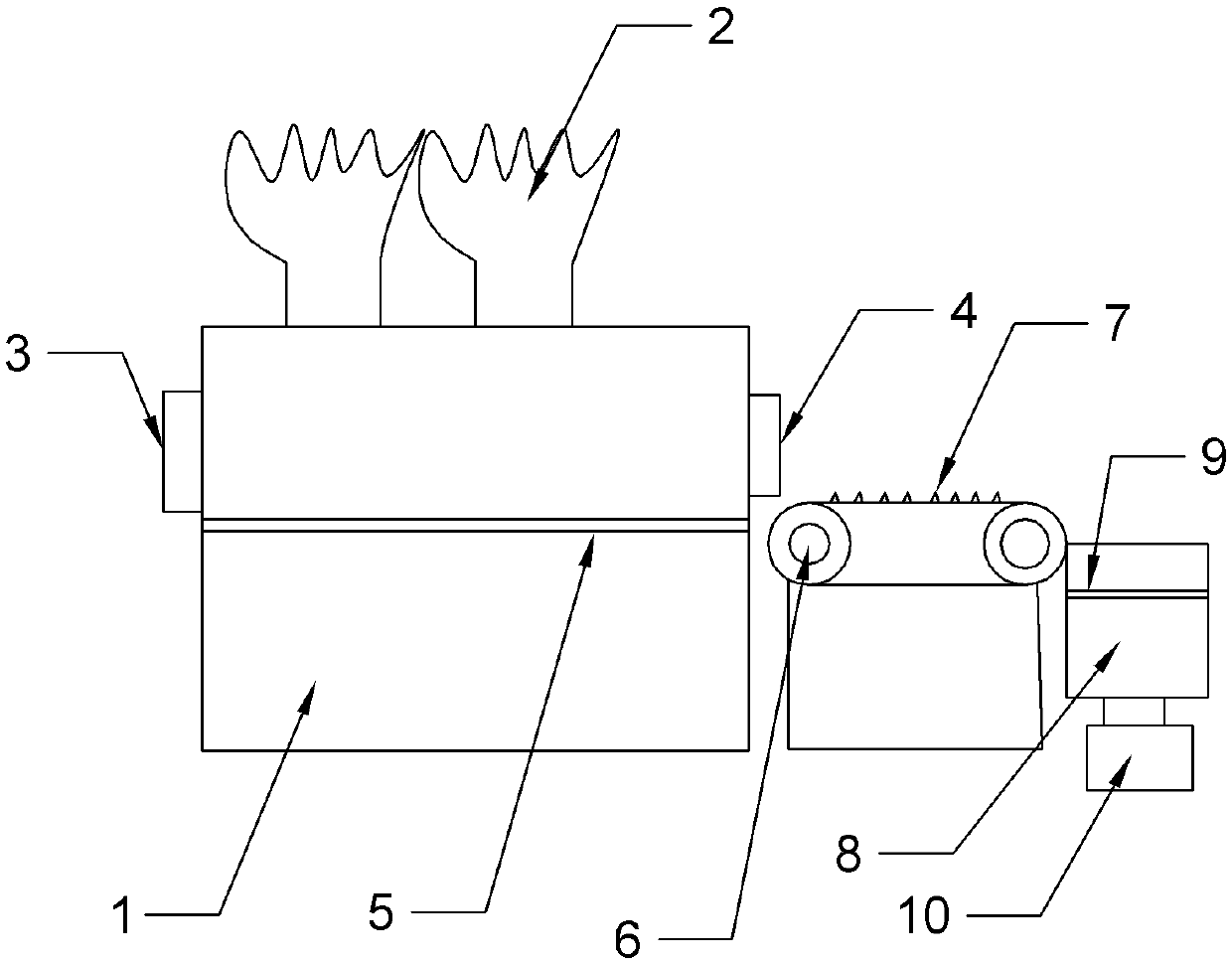

[0014] The marks in the accompanying drawings of the present invention are: oil tank body 1, gloves 2, feed port 3, discharge port 4, operating platform 5, transmission mechanism 6, protrusion 7, oil drain barrel 8, filter screen 9, motor 10 .

[0015] Such as figure 1 As shown, the installation oil tank for the vane pump includes the oil tank body 1. Two gloves 2 are arranged above the oil tank body 1. The gloves 2 are made of leather materials. The gloves 2 and the oil tank body 1 are connected through the installation pipe, so that It is convenient for people to access the vane pump through the oil tank body 1 in reverse. The side wall of the oil tank body 1 is provided with a material inlet 3, and the corresponding side wall of the oil tank body 1 is provided with a discharge port 4. The oil tank body 1 is provided with an operation platform 5, and an oil passage hole is arranged on the operation platform 5, and the oil passage hole Arranged in a uniform matrix, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com