Connecting device for polymer pipeline and metal joint

A technology of metal joints and connecting devices, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of affecting the service life of polymer pipelines, polymer pipeline damage, and contact pressure reduction, etc., to achieve Large social and economic benefits, guaranteed service life, and anti-rotation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

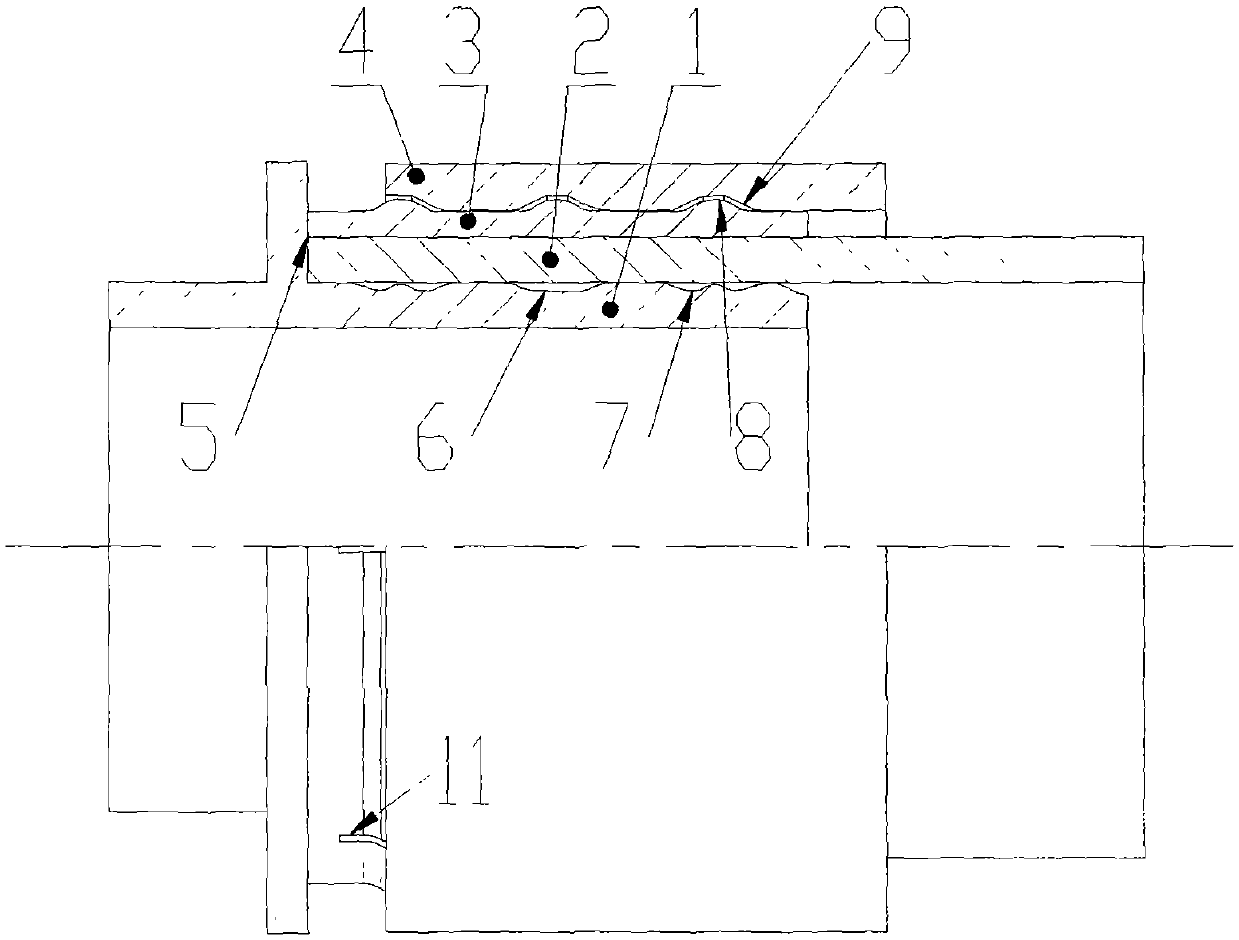

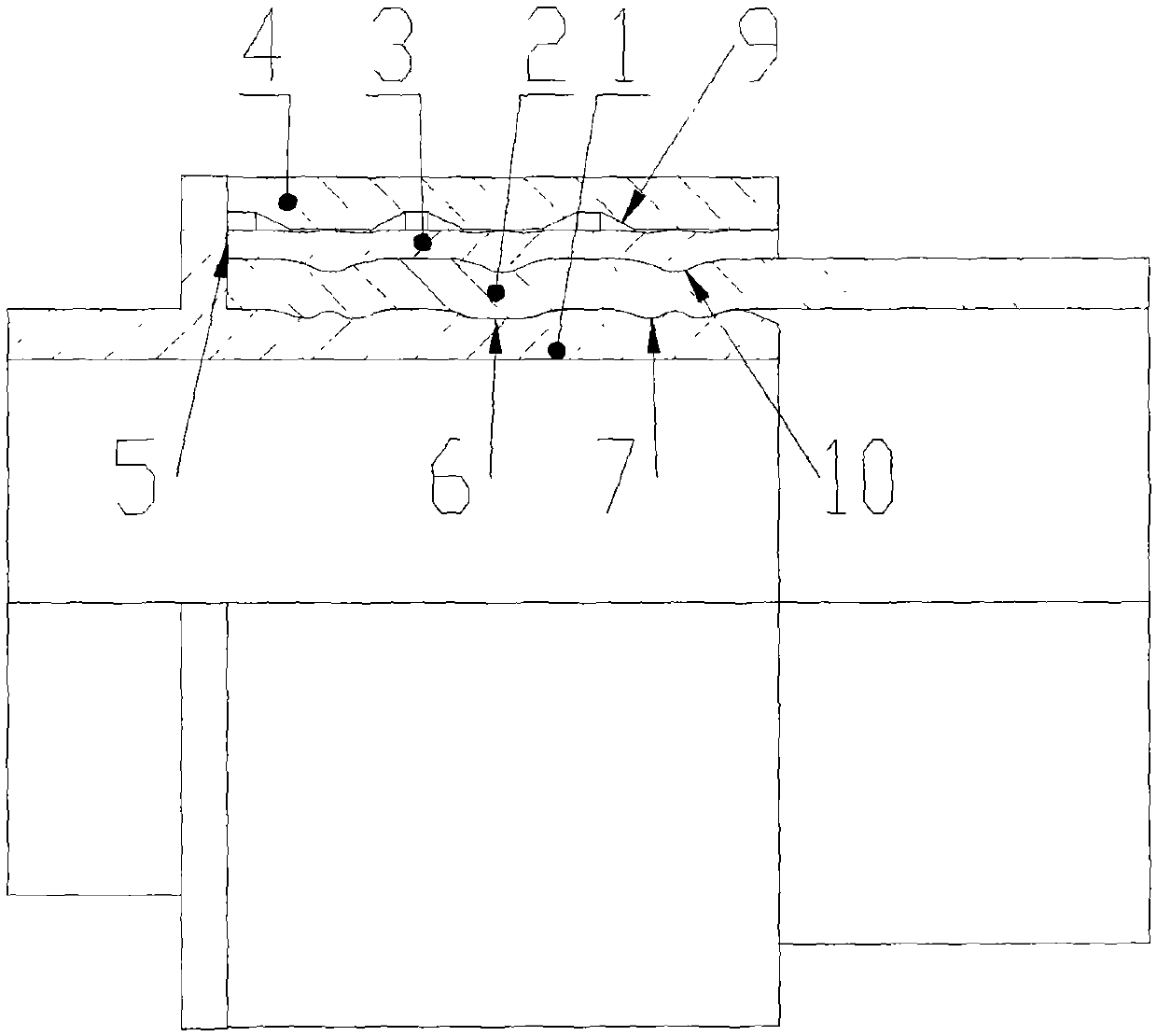

[0020] Embodiments of the present invention are described with reference to the accompanying drawings, which are combined below figure 1 and figure 2 The present invention will be specifically described. A connecting device for polymer pipes and metal joints, comprising metal joints 1 , shrink rings 3 and compression rings 4 . The metal joint 1, the shrink ring 3 and the compression ring 4 are all made of metal.

[0021] The outer circumferential surface of the shrink ring 3 is provided with an annular protrusion A8, and is also provided with a shrink groove 11 that opens inward and outward along the axial direction. Corresponding to the position of the annular protrusion A8 of the shrink ring 3, the inner circumferential surface of the compression ring 4 is provided with an annular groove C9. The shrinking ring 3 is pre-inserted into the pressing ring 4 , so that the annular protrusion A8 of the shrinking ring 3 is inserted into the annular groove C9 of the pressing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com