A phase-change wave rotor self-cascading refrigeration system and its working method

A technology of self-cascading and wave rotors, applied in the field of mechanical refrigeration, can solve the problems of inability to achieve low-temperature supercharging effect, large pressure ratio of single-stage compressors, and reduced refrigeration performance, and achieve easy development of equipment, lower pressure ratio, and structural small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 A phase change wave rotor self-cascading refrigeration system using mixed refrigerants.

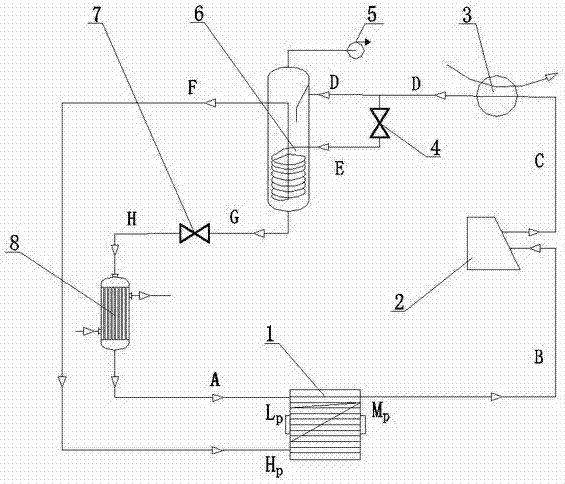

[0018] figure 1 A phase change wave rotor self-cascading refrigeration system with mixed refrigerant is shown. The phase change wave rotor self-cascading refrigeration system with mixed refrigerant in the figure includes a self-cascading refrigeration device and a supercharging device. The self-cascading refrigeration device includes a condenser 3, a high-temperature throttle valve 4, a non-condensable gas pump 5, a low-temperature throttle valve 7, an evaporator 8 and a self-cascading supercooler 6, and the self-cascading supercooler 6 is used to refrigerate the high temperature The refrigerant exchanges heat with the low-temperature refrigerant and discharges non-condensable gas at the same time. The supercharging device is composed of a phase change wave rotor supercharger 1 and a steam compressor 2 . The medium-pressure steam outlet Mp of the phase change wave r...

Embodiment 2

[0021] Example 2 Multi-stage vapor compression refrigeration system using a single refrigerant

[0022] In principle, the process and equipment layout remain unchanged, and the mixed refrigerant is replaced with a single refrigerant, so that a multi-stage vapor compression refrigeration system using a single refrigerant can be realized.

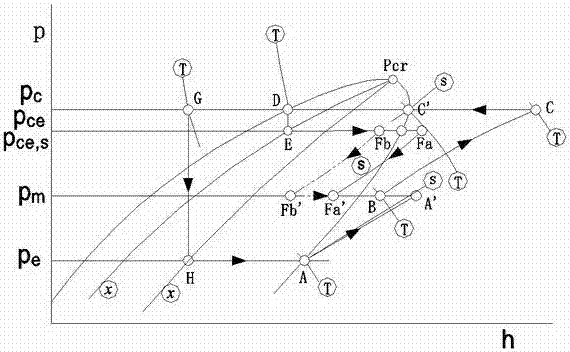

[0023] The high-pressure supersaturated vapor at point Fb expands isentropically to Fb' in the phase-change wave rotor supercharger 1, and the low-pressure saturated vapor at point A undergoes less than isentropic compression to A' in the phase-change wave rotor supercharger 1 The superheated steam at B is compressed by the steam compressor 2 to the high-temperature and high-pressure superheated steam at C, and is cooled to the high-pressure saturated liquid at D through equal pressure through the condenser 3, and the high-pressure saturated liquid at D is divided into low-temperature refrigeration Two paths of refrigerant and high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com