A method for real-time on-line safe determination of explosive triboelectric voltage

A technology of friction electrification and voltage value, which is applied in the direction of measuring current/voltage, measuring only voltage, measuring electrical variables, etc., to eliminate safety risks and ensure the effect of life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

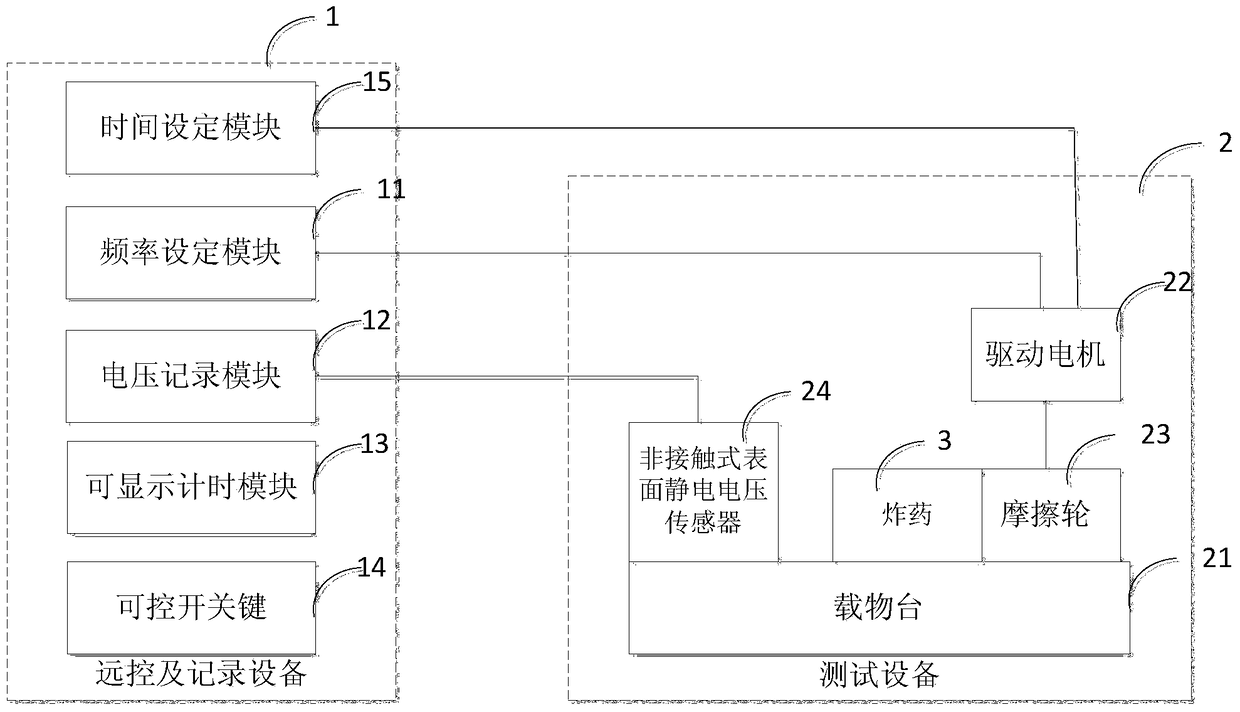

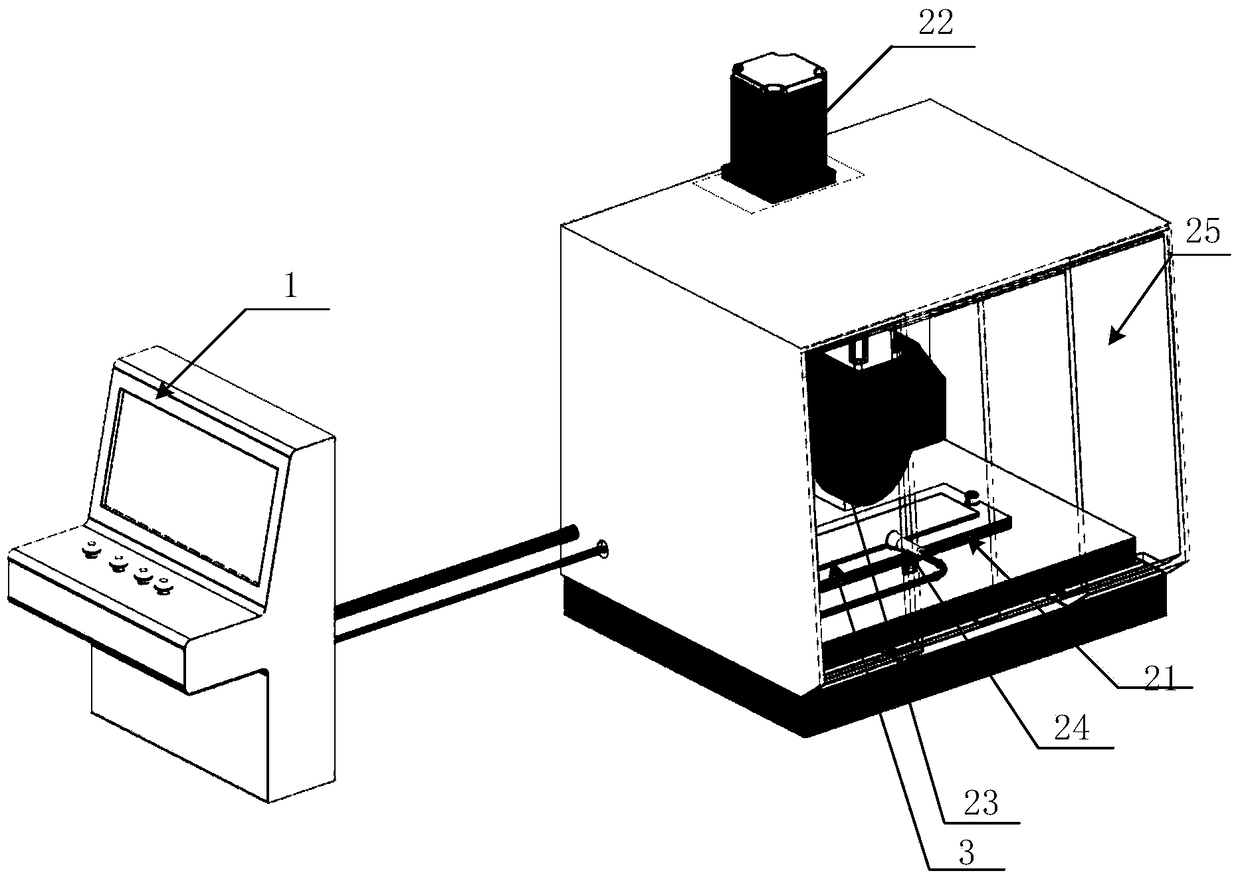

[0026] figure 1 It is a functional block diagram of a system for real-time on-line safety measurement of explosive triboelectrification voltage value provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the system includes remote control and recording equipment 1, testing equipment 2 and explosion-proof room 25. The explosion-proof room 25 is a closed space and is provided with explosion-proof glass observation windows.

[0027] The remote control and recording device 1 includes a frequency setting module 11 , a voltage recording module 12 , a displayable timing module 13 , a controllable switch key 14 , and a time setting module 15 . In this embodiment, the controllable switch key 14 is a key-inserted controllable switch, and the remote control and recording device 1 is activated or deactivated by the controllable switch key 14 .

[0028] The testing device 2 includes a stage 21 , a driving motor 22 , a friction wheel 23 connected to the driving mot...

Embodiment 2

[0033] Embodiment 2 provides a real-time online method for safely measuring the frictional electrification voltage value of explosives, which includes the following steps.

[0034] Step (S1): The person in charge of the test confirms that the remote control and recording equipment and the test equipment are both turned off, and pulls out the key of the controllable on-off key of the remote control and recording equipment in his hand. Step (S2) is executed after step (S1) is executed.

[0035] Step (S2): Fixing the explosive on the object platform in the explosion-proof room, so that the friction wheel can effectively contact the explosive. After step (S2) is executed, step (S3) is executed.

[0036] Step (S3): Place the non-contact surface electrostatic voltage sensor at a distance of 2 cm to 10 cm from the explosive, and use a conductive rod to derive the accumulated charge on the surface before the explosive test. Step (S4) is executed after step (S3) is executed.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com