Tire

A tire and bead technology, applied in tire parts, treads, transportation and packaging, etc., can solve problems such as apex deformation, and achieve the effect of restraining deformation, superior durability and restraining damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

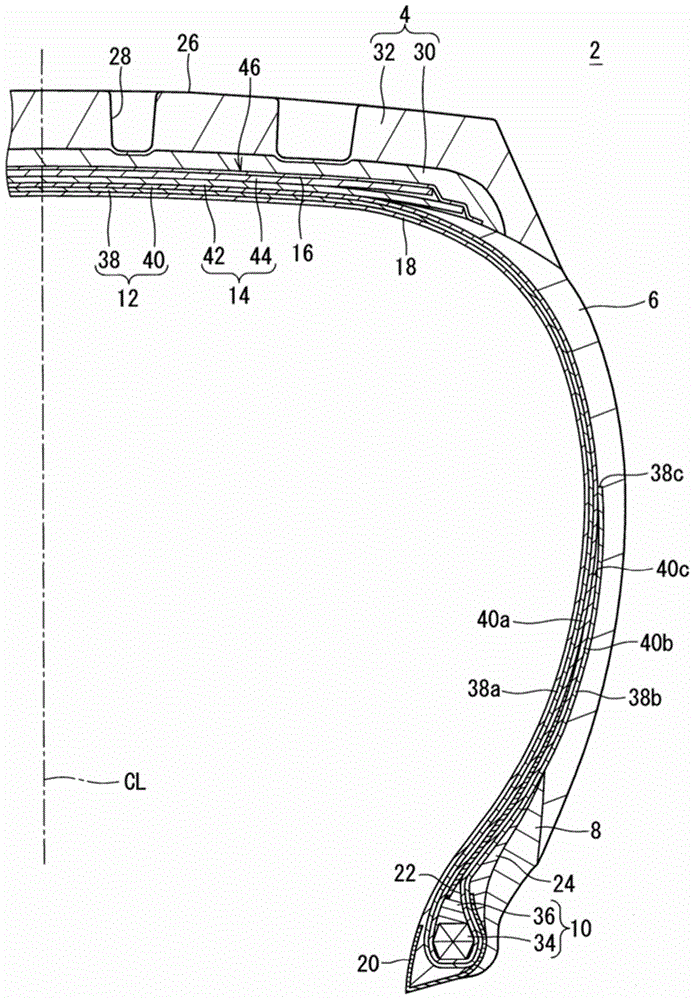

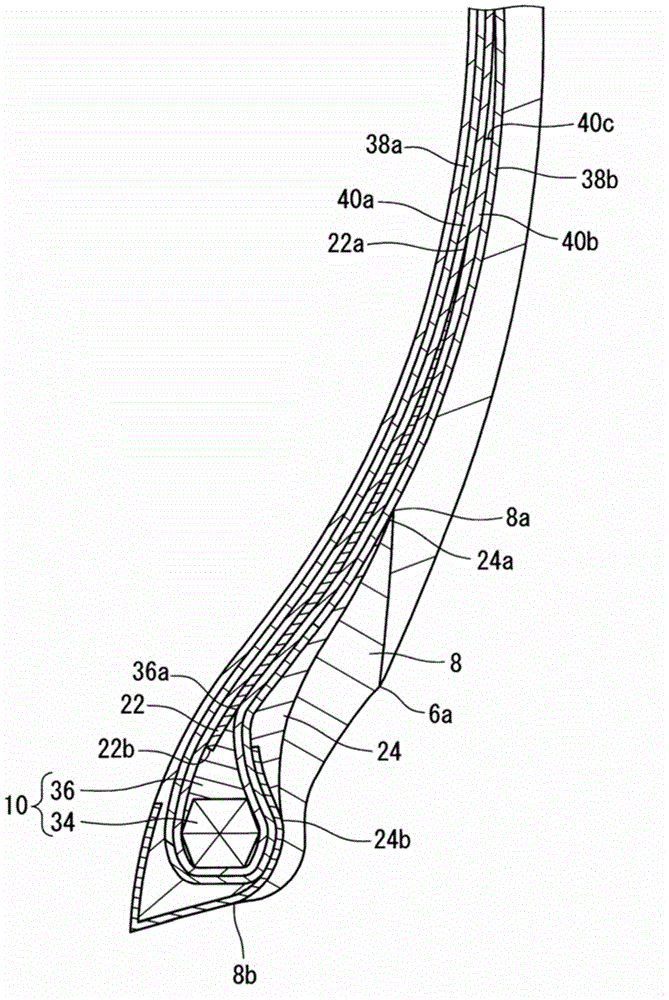

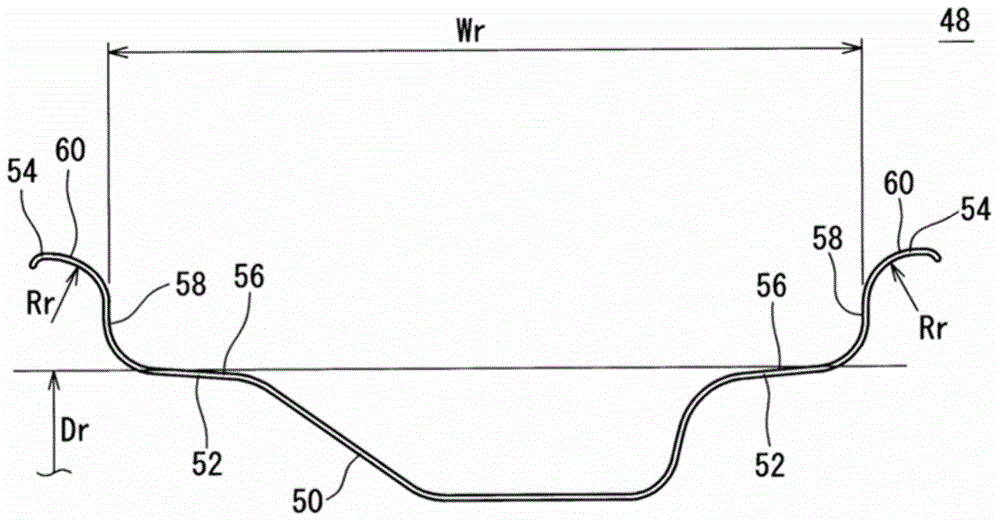

[0069] In addition to not having rubber belts and fillers, the production has figure 1 The structure of the tire shown. The size of this tire is LT265 / 75R16. The position angle α of the front end of the apex of this tire is 30° when it is assembled on a normal rim with a normal internal pressure and a load of 120% of the normal load.

Embodiment 2-4 and comparative example 2-3

[0073] Tires were obtained in the same manner as in Example 1 except that the position angle α of the front end of the apex was as shown in Table 1 below.

Embodiment 5-6

[0075] A tire was obtained in the same manner as in Example 1 except that the filler was included. Table 2 shows the ratio (Tf / Tt) of the thickness Tf of the filler to the thickness Tt of the tire when assembled on a normal rim with a normal internal pressure and a load of 120% of the normal load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com