A positioning mechanism for double-speed chain assembly line and double-speed chain assembly line equipment

A positioning mechanism and assembly line technology, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of fast and accurate positioning of materials, and achieve the effect of adapting to automated operations, fast positioning, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

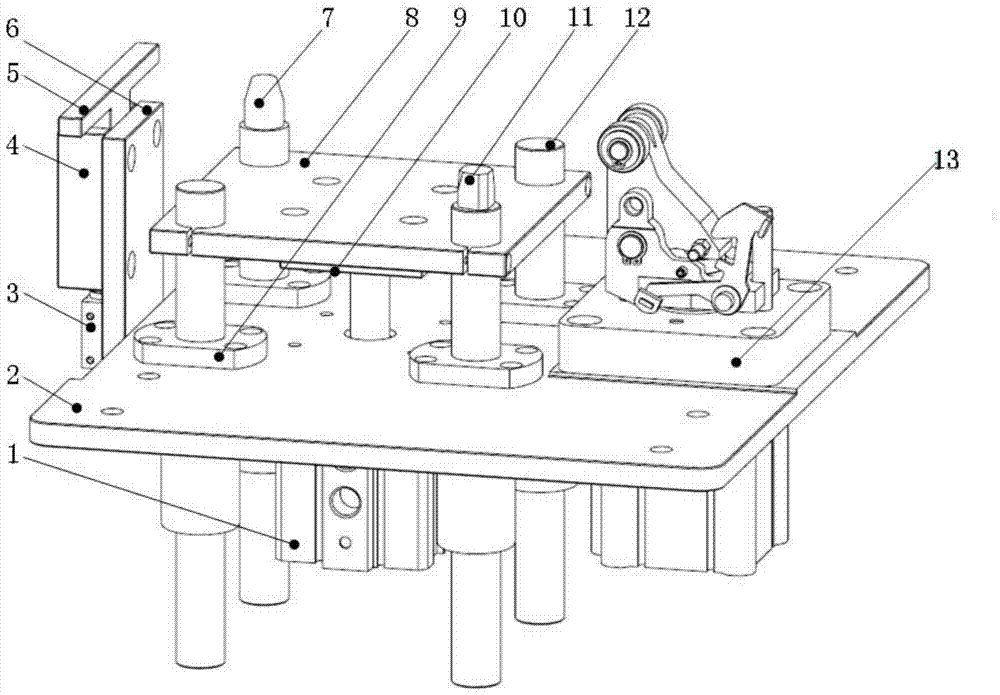

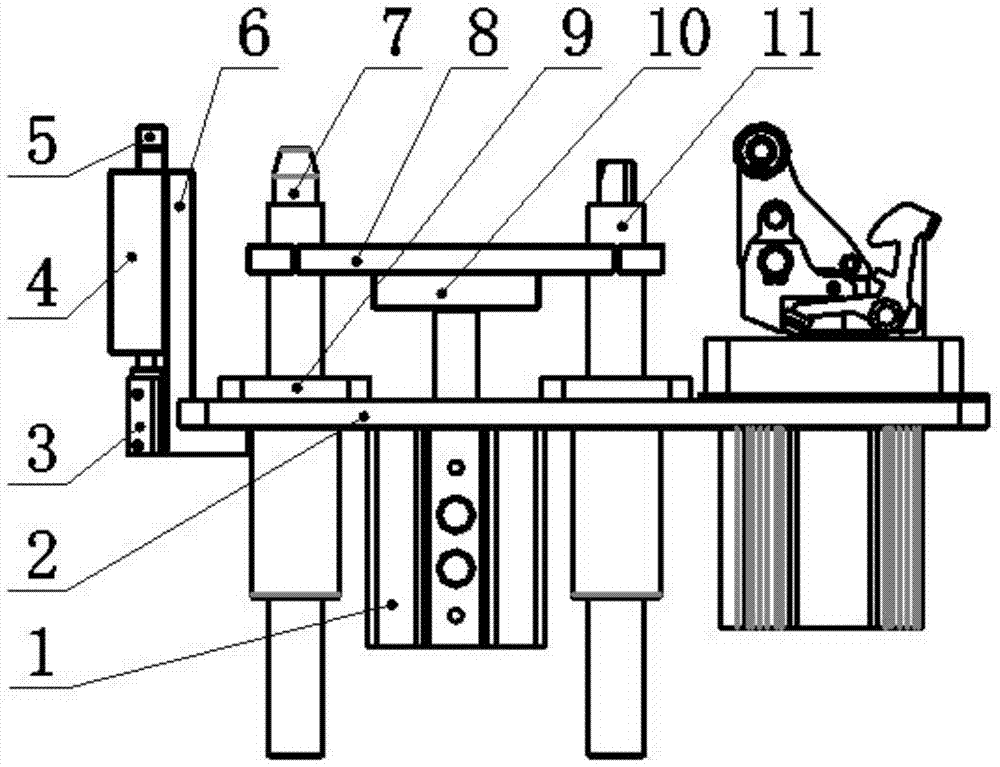

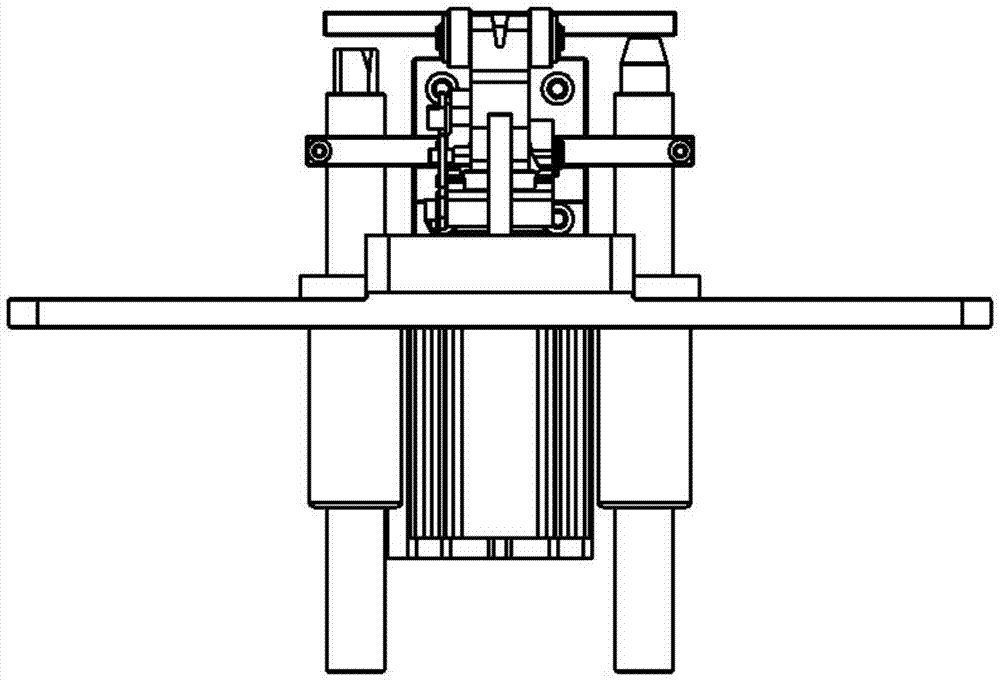

[0035] An embodiment of the present invention provides a positioning mechanism for a double-speed chain assembly line, which generally includes a front blocking device, a rear blocking device, a vertical positioning device, and a mounting plate.

[0036] like figure 1 As shown in , the front blocking device is installed on the upper surface of one end of the mounting plate 2, and is located in the direction in which the material advances. Then the blocking device is installed on the end face of the other end of the mounting plate, and is located in the direction in which the material retreats. Both the front blocking device and the rear blocking device have driving devices and liftable parts for blocking materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com