Double-lifting-pin lifting tool for avoiding flat rack container dropping accident

A container and falling container technology, applied in the field of spreaders to prevent frame container falling accidents, to achieve the effect of improving equipment operation safety and efficiency, and reducing the incidence of false locking of spreaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

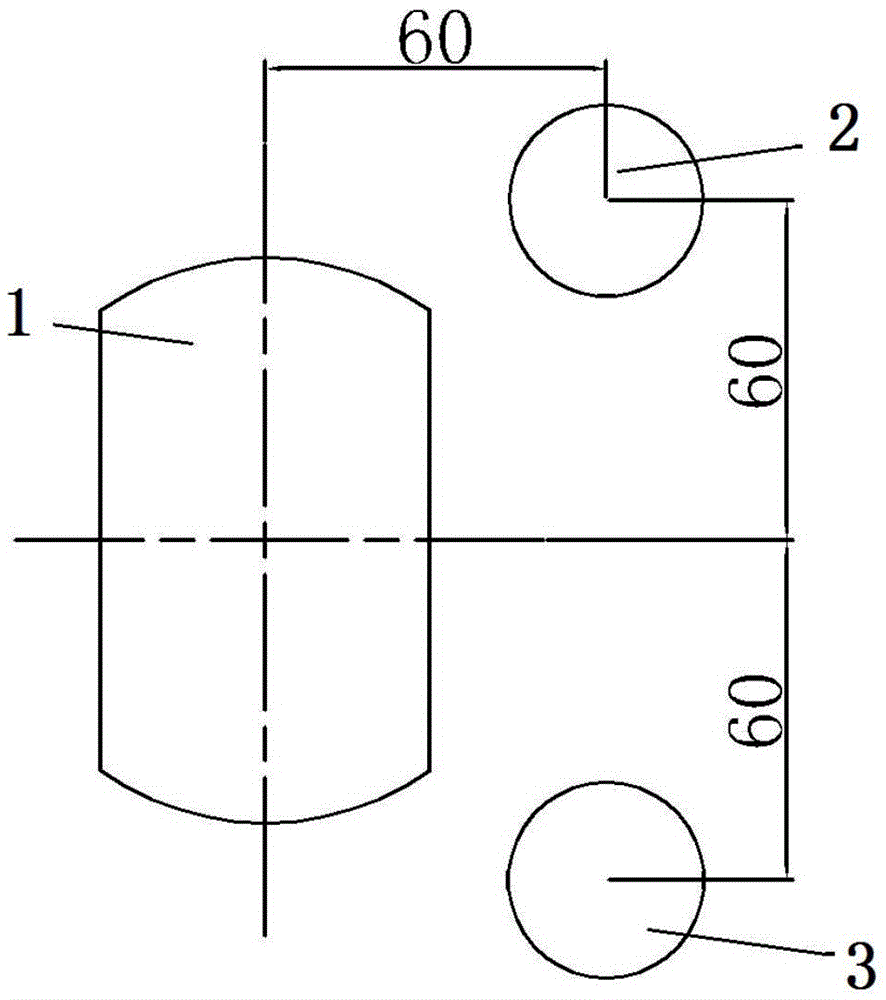

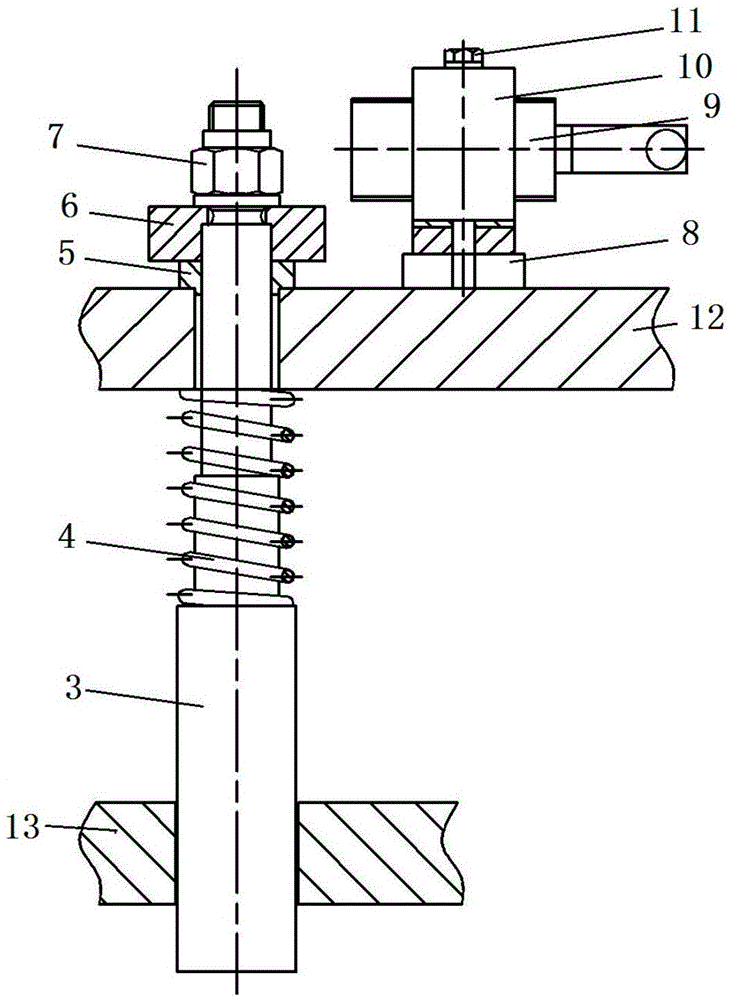

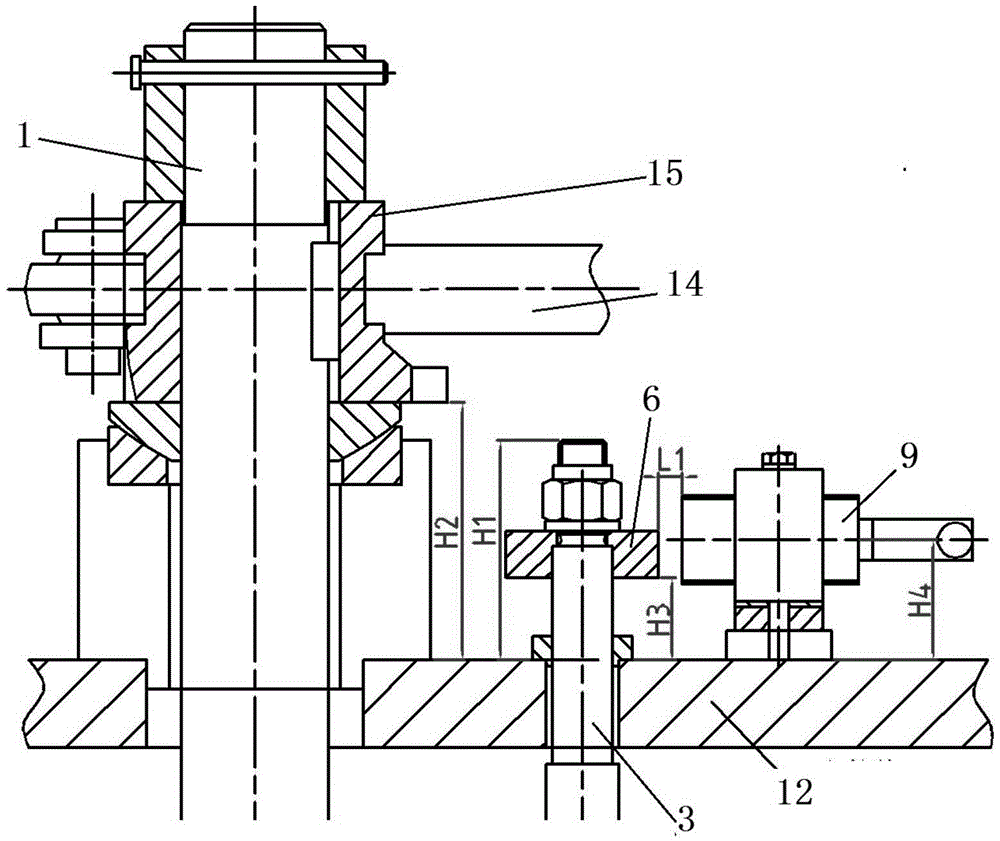

[0020] Such as figure 1 As shown, a double ejector pin spreader for preventing frame container fall accidents includes a lock head, a twist lock 1 installed on a box body 12 and an ejector mechanism. Twist lock 1 is provided with two ejector mechanisms at symmetrical positions on the center line of the lock head to form a double ejector pin structure; a detection limit device is installed next to the ejector mechanism, and is connected in series with the ejector limit to realize chain control.

[0021] Each lock head corresponds to a set of ejector pin device. Install the ejector pin B3 at the symmetrical position of the original ejector pin A2 with respect to the center line of the lock head, and form a double ejector pin structure at each turn lock, and its position structure is as follows figure 2 shown. By installing a detection limit on the upper box body 12 and connecting it in series with the original ejector pin limit, chain control is realized. One crane has four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com