Lifting, conveying, loading and unloading device for hole digging of underground pipe gallery vertical shaft

A technology of loading and unloading device and underground pipe gallery, which is used in transportation and packaging, earthmoving machines/shovels, cranes of trolleys, etc. Convenient and fast, wide application range, saving investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

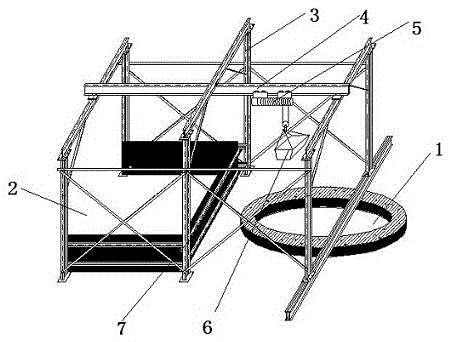

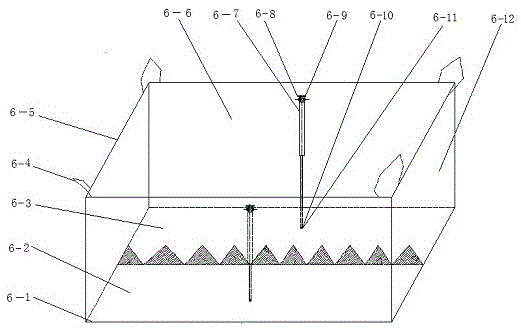

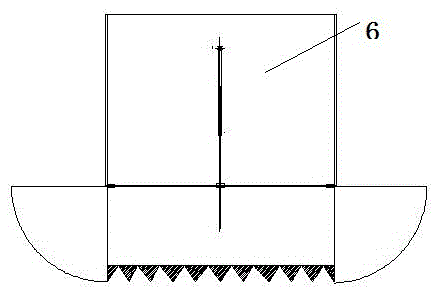

[0018] In the figure, a lifting and loading and unloading device for digging holes in an underground pipe gallery shaft of the present invention includes a shaft 1, a discharge area 2, a support frame 3, a lifting and unloading beam 4, an electric hoist 5, a loading hopper 6, and a living hinge 6 -1, hopper left bottom plate 6-2, hopper right bottom plate 6-3, hopper lifting lug 6-4, hopper short side side plate 6-5, hopper long side side plate 6-6, automatic telescopic oil cylinder 6-7, oil cylinder Upper fixed ear plate 6-8, oil cylinder connecting pin 6-9, oil cylinder lower connecting ear plate 6-10, oil cylinder lower connecting pin 6-11, hopper short side plate 6-12, baffle plate 7.

[0019] A lifting and unloading device for digging holes in an underground pipe gallery shaft, the lifting and unloading device includes a shaft 1, a discharge area 2, a support frame 3, a lifting and unloading beam 4, an electric hoist 5, and a loading hopper 6; the shaft 1 A support frame ...

Embodiment 2

[0026] The top of the shaft 1 is provided with a support frame 3, and the top of the support frame 3 is provided with two horizontal lifting and unloading beams 4, and the lifting and unloading beams 4 are all provided with an electric hoist 5, and the electric hoist 5 is connected with the loading hopper 6 through a wire rope; the support frame 3 is provided with a discharge area 2 isolated from the shaft 1; two horizontal beams 4 for lifting and unloading, one for lifting and the other for discharging, work interactively and cooperatively to improve construction efficiency. Progress, other with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com