Shield construction residue soil transferring device

A transfer device and muck technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high difficulty, small equipment installation space, and narrow shield construction space, etc., and achieves convenient operation, simple and compact structure, and improved construction. The effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

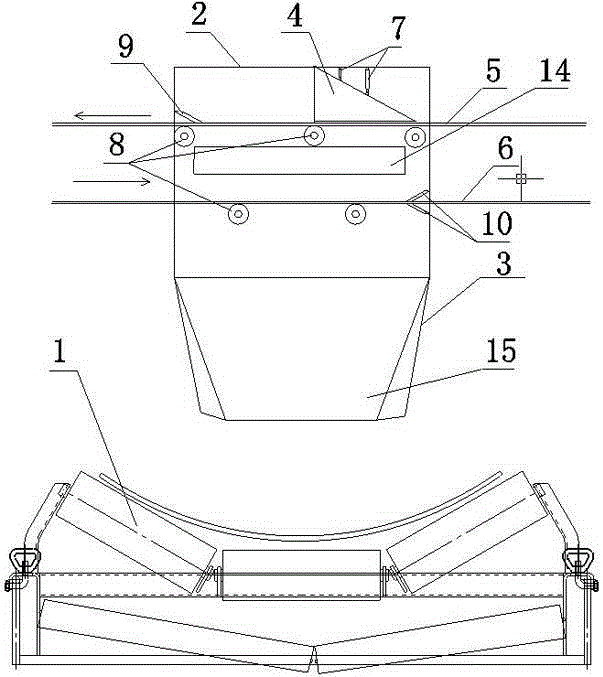

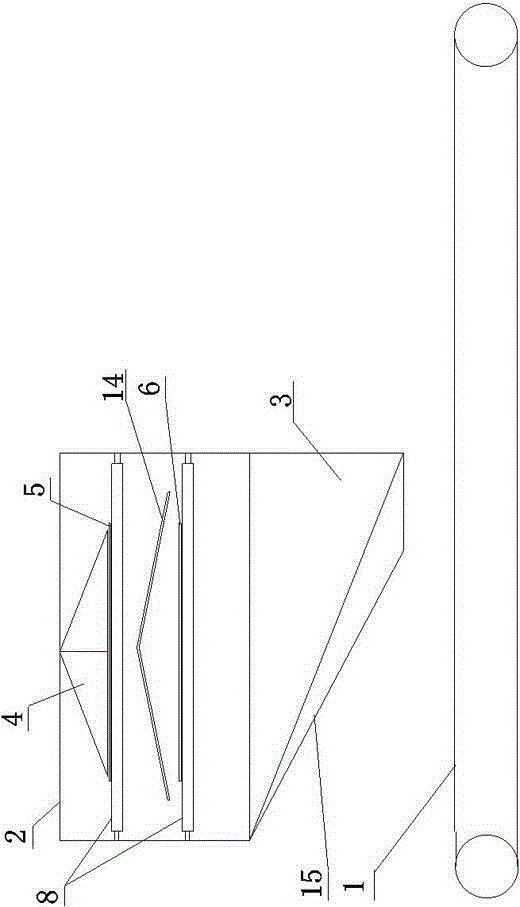

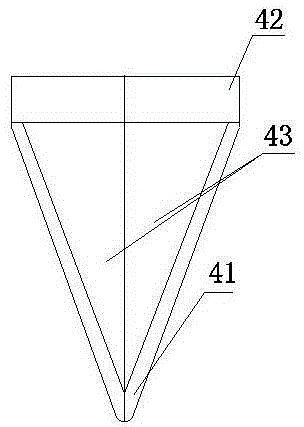

[0023] like figure 1 , 2 A kind of shield construction slag transfer device shown in . However, the inner top of the housing 2 and above the upper belt 5 are provided with a central mud scraper 4, the central mud scraper 4 includes a vertical baffle 42 and a dregs distributor connected thereto, and the dregs The sharp corner of the soil diverter faces to the right, the vertical baffle 42 matches the width of the upper belt 5 , and the transfer belt conveyor 1 is located below the discharge chute 3 .

[0024] The working principle is as follows. The muck on the upper belt 5 of the shield belt machine is diverted to both sides through the central scraper 4, and the opening where the upper belt 5 enters the shell 2 must ensure that all the muck transported enters and scrapes down to the dregs. Along the inner wall of the housing 2, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com