Vacuum ring main unit with gas detection function and manufacturing method thereof

A technology of gas detection and production method, applied in the field of ring network cabinets, can solve the problems of no gas detection function, hidden dangers of personnel and equipment safety, etc., and achieve the effects of short recovery time, fast response speed, and large market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

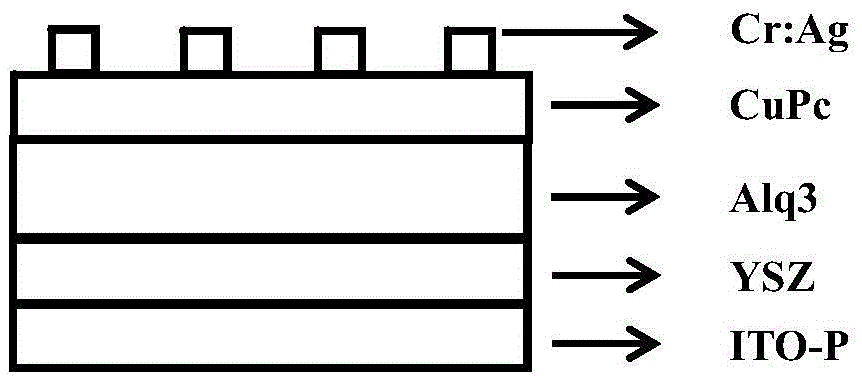

[0050] A vacuum ring main unit with gas detection function is characterized in that a gas detection module is installed outside the cabinet body of the vacuum ring main unit, and the gas detection module is made by the following method:

[0051] The specific process is: surface cleaning and treatment of conductive plastic ITO-PET—substrate placed in a vacuum chamber—vacuum vapor deposition of organic layers—evaporated metal electrodes—package or test.

[0052] 1. Conductive plastic ITO-PET cleaning

[0053] First, cut ITO-PET of a specific size, scrub the ITO-PET substrate with special detergent and clean cloth to remove various oil stains on the substrate, and then put in compound biological enzyme solution, deionized water, In acetone and ethanol, each ultrasonic for 55min; then, dry the ITO-PET with high-purity nitrogen to evaporate the ethanol, then put it into the pretreatment chamber, continuously feed high-purity oxygen, and bombard the substrate with plasma for 5min; ...

Embodiment 2

[0068] A vacuum ring main unit with gas detection function is characterized in that a gas detection module is installed outside the cabinet body of the vacuum ring main unit, and the gas detection module is made by the following method:

[0069] The specific process is: surface cleaning and treatment of conductive plastic ITO-PET—substrate placed in a vacuum chamber—vacuum vapor deposition of organic layers—evaporated metal electrodes—package or test.

[0070] 1. Conductive plastic ITO-PET cleaning

[0071] First, cut ITO-PET of specific size, scrub the ITO-PET substrate with special detergent and clean cloth to remove various oil stains on the substrate, and then put it in deionized water, acetone and ethanol in turn, Ultrasound for 15min each; then, dry the ITO-PET with high-purity nitrogen to evaporate the ethanol, then put it into the pretreatment chamber, continuously feed high-purity oxygen, and bombard the substrate with plasma for 5min;

[0072] 2. Preparation of Poro...

Embodiment 3

[0085] A vacuum ring main unit with gas detection function is characterized in that a gas detection module is installed outside the cabinet body of the vacuum ring main unit, and the gas detection module is made by the following method:

[0086] The specific process is: surface cleaning and treatment of conductive plastic ITO-PET—substrate placed in a vacuum chamber—vacuum vapor deposition of organic layers—evaporated metal electrodes—package or test.

[0087] 1. Conductive plastic ITO-PET cleaning

[0088] First, cut ITO-PET of a specific size, scrub the ITO-PET substrate with special detergent and clean cloth to remove various oil stains on the substrate, and then put in compound biological enzyme solution, deionized water, In acetone and ethanol, each ultrasonic for 15min; then, dry the ITO-PET with high-purity nitrogen to evaporate the ethanol, and then put it into the pretreatment chamber, continuously feed high-purity oxygen, and bombard the substrate with plasma for 5mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Luminous brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com