Method and device for optimizing aircraft wing structure

A technology of wing structure and optimization method, applied in the direction of design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of unfavorable continuous processing and forming of aircraft wings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

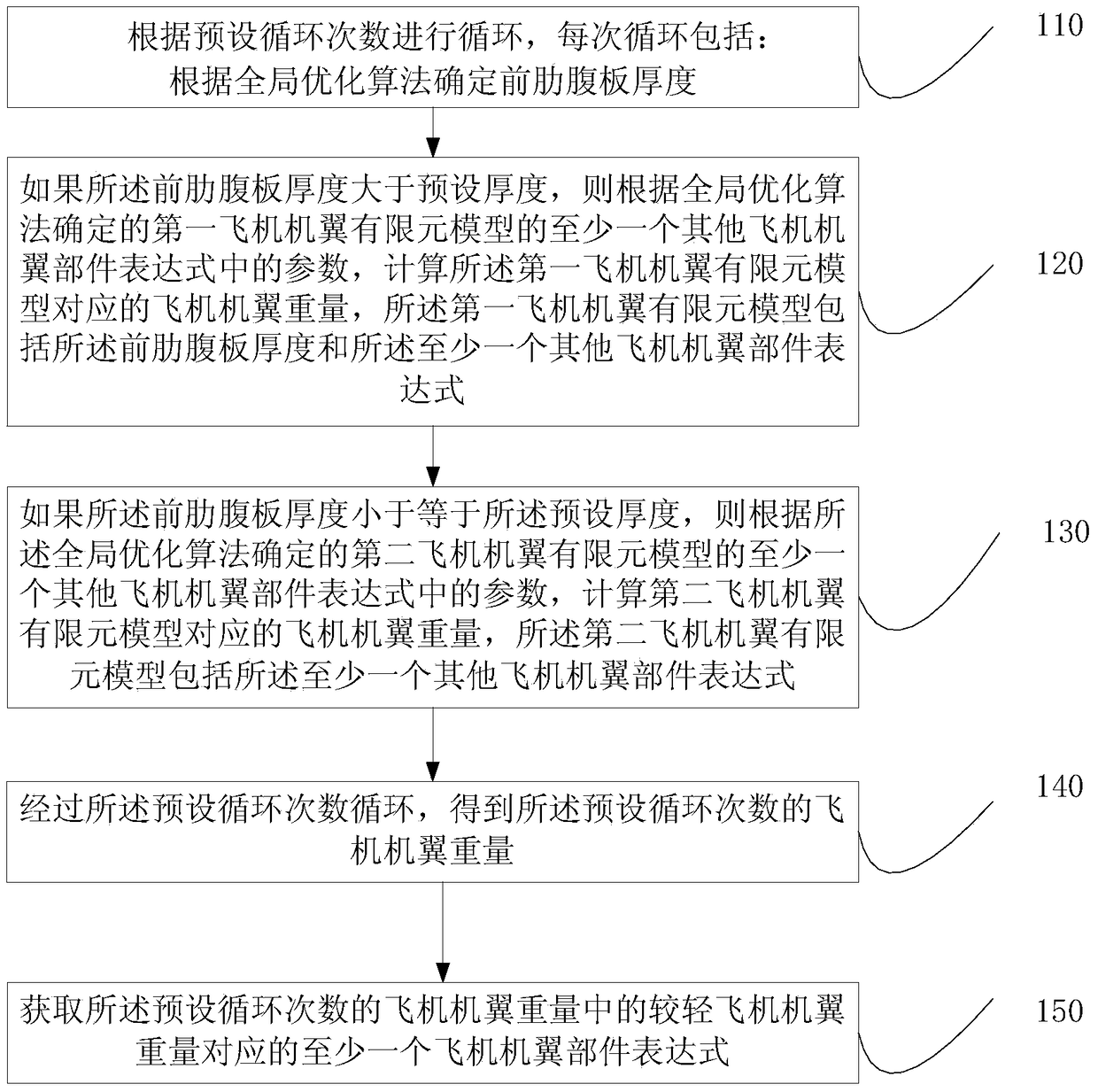

[0030] Figure 2A It is a flow chart of the method for optimizing the wing structure of an aircraft provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation of optimizing the wing of an aircraft. The method can be executed by a program, and specifically includes the following steps:

[0031] Step 110, perform the cycle according to the preset number of cycles, and each cycle includes: determining the web thickness of the front rib according to the global optimization algorithm;

[0032] Specifically, the number of preset cycles is set in the user interface of the optimization software, for example, it can be set to 1000 times. When each cycle is executed, the thickness of the front rib web must be determined first, so as to find the specified aircraft wing finite element according to the thickness. The element model of the aircraft wing is optimized, and the finite element model of the aircraft wing that meets the requirements is obtain...

Embodiment 2

[0071] image 3 The flow chart of the optimization method for the aircraft wing structure provided by Embodiment 2 of the present invention. This embodiment is based on Embodiment 1. Before calculating the weight of the aircraft wing corresponding to the first aircraft wing finite element model, it is also Including the following steps:

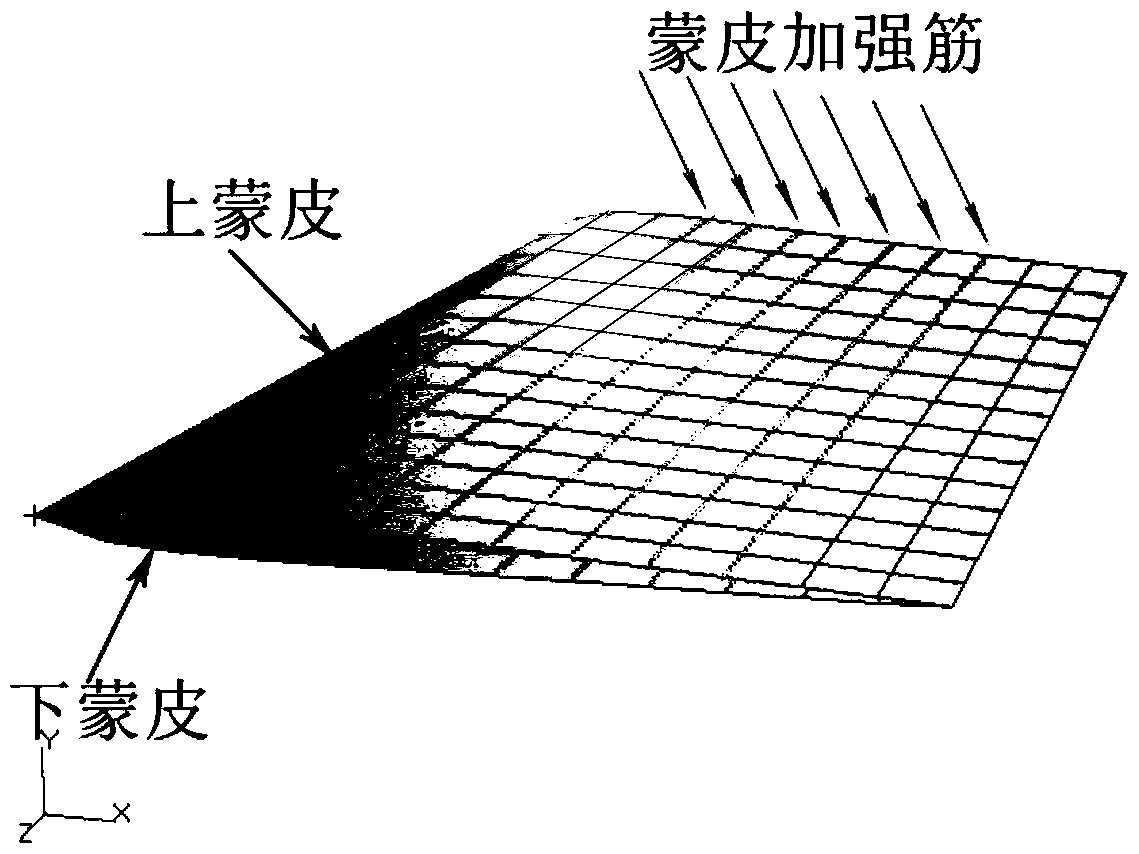

[0072] Step 210, applying the at least one working condition load to the aircraft wing skin nodes constrained by root fixation.

[0073] According to the multi-condition loads checked by the strength, they are respectively applied to the skin nodes of the aircraft wing to form the load boundary conditions of the model; when the loads are applied, one type of load can be applied, or more than one type can be applied Condition load.

[0074] At the same time, the root of the aircraft wing is fixedly supported to form a constraint boundary condition, which is used to add boundary conditions to the subsequent static and buckling analysis of the...

Embodiment 3

[0102] Figure 4 The flow chart of the optimization method for the aircraft wing structure provided by Embodiment 3 of the present invention, this embodiment is based on Embodiment 1, and also includes the following steps before calculating the weight of the aircraft wing corresponding to the second aircraft wing finite element model :

[0103] Step 310, applying the at least one working condition load to the aircraft wing skin nodes constrained by root fixation.

[0104] According to the multi-condition loads checked by the strength, they are respectively applied to the skin nodes of the aircraft wing to form the load boundary conditions of the model; when the loads are applied, one type of load can be applied, or more than one type can be applied Condition load.

[0105] At the same time, the root of the aircraft wing is fixedly supported to form a constraint boundary condition, which is used to add boundary conditions to the subsequent static and buckling analysis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com