High sensitivity PVDF film

A high-sensitivity, silica-gel layer technology, applied in the field of sensors, can solve the problems of PVDF film perception sensitivity to be improved, achieve high potential value, improve perception sensitivity, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

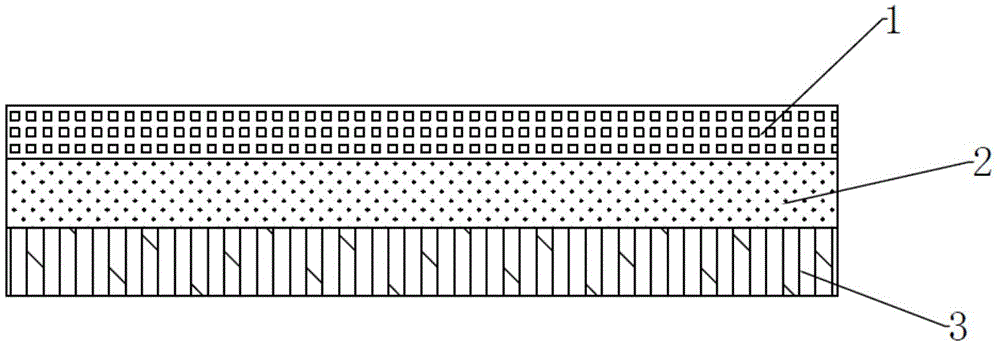

[0010] A high-sensitivity PVDF membrane, comprising a silica gel layer 1, a PVDF layer 2, and a ceramic layer 3, wherein the ceramic layer 3 is located at the bottom of the high-sensitivity PVDF membrane, the silica gel layer 1 is located at the top of the high-sensitivity PVDF membrane, and the PVDF layer 2 Located between the silica gel layer 1 and the ceramic layer 3, the surfaces of the above silica gel layer 1, PVDF layer 2 and ceramic layer 3 are tightly bonded to form a whole, and the thickness of the ceramic layer 3 is not greater than the thickness of the PVDF layer 2.

[0011] The embodiments of the present invention have been described in detail above, but the content is only a preferred embodiment of the present invention, and is not intended to limit the present invention. All modifications, equivalent replacements and improvements made within the application scope of the present invention shall be included in the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com